A kind of nickel-titanium shape memory alloy square thin wire material continuous processing method

A nickel-titanium alloy, memory alloy technology, applied in metal processing equipment, metal wire drawing, manufacturing tools, etc., can solve the problems of easy surface scratches, low production efficiency, low strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0027] It should be noted that the structures, proportions, sizes, etc. shown in this specification are only used to cooperate with the content disclosed in the specification for the understanding and reading of those familiar with this technology, and are not used to limit the conditions for the implementation of the present invention , any modification of structure, change of proportional relationship or adjustment of size shall still fall within the scope covered by the technical content disclosed in the present invention without affecting the effect and purpose of the present invention. .

[0028] At the same time, terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and are not used to limit this specification. The practicable scope of the invention and the change or adjustment of its relative relationship shall also be regarded as the practicable scope of the present invention without...

Embodiment 1

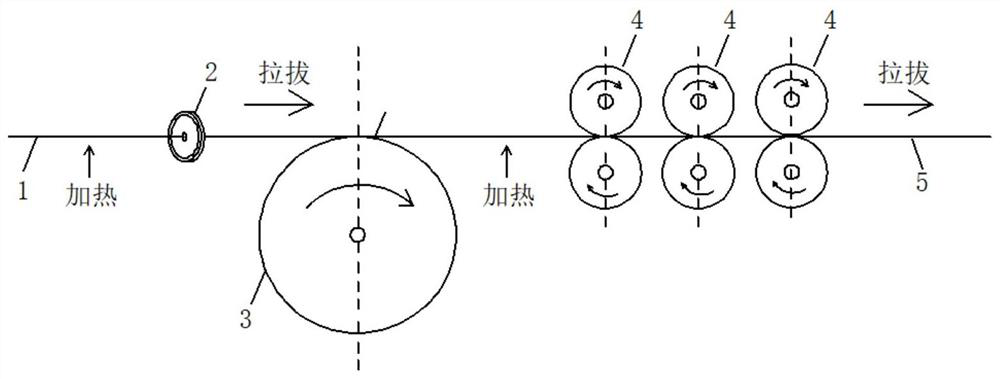

[0030] The invention discloses a method for continuously processing nickel-titanium shape memory alloy square thin wires, which comprises the following steps:

[0031] Step 1) surface-treating the Ф3mm nickel-titanium alloy thin round wire billet;

[0032] Step 2) performing square hot die drawing and hot roller drawing on the nickel-titanium alloy fine round wire blank after surface treatment in step 1), to obtain the nickel-titanium alloy square thin wire material;

[0033] Step 3) Perform square cold die drawing and online straightening heat treatment on the nickel-titanium alloy square thin wire in step 2), to obtain the nickel-titanium shape memory alloy square thin wire.

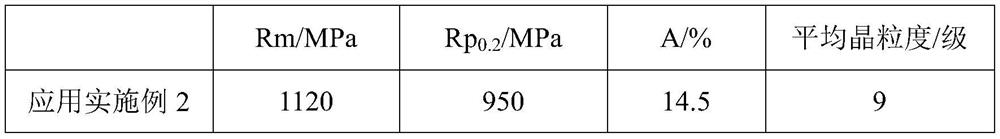

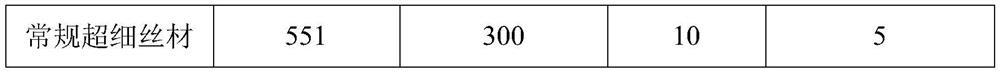

Embodiment 2

[0035] The invention discloses a method for continuously processing nickel-titanium shape memory alloy square thin wires, which comprises the following steps:

[0036] Step 1) surface-treating the Ф3mm nickel-titanium alloy thin round wire billet;

[0037] Step 2) performing square hot die drawing and hot roller drawing on the nickel-titanium alloy fine round wire blank after surface treatment in step 1), to obtain the nickel-titanium alloy square thin wire material;

[0038] Step 3) Perform square cold die drawing and online straightening heat treatment on the nickel-titanium alloy square thin wire in step 2), to obtain the nickel-titanium shape memory alloy square thin wire.

[0039]Preferably, the surface treatment in the step 1) is to clean and dry the Ф3mm nickel-titanium alloy thin round wire billet after hot drawing in the early stage, check and grind to remove cracks, folds, and burrs, and then coat the surface with graphite Emulsion lubricant, then fully dried at 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com