3D printing tantalum rod

A 3D printing and threaded part technology, applied in the field of 3D printing tantalum rods, can solve problems such as uneven distribution of pore structure, poor bone conduction and bone fusion performance, and treatment failure, so as to avoid unsatisfactory bone ingrowth, avoid surgical revision, The effect of promoting bone conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the technical solution of the present invention, a 3D printing tantalum rod of the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

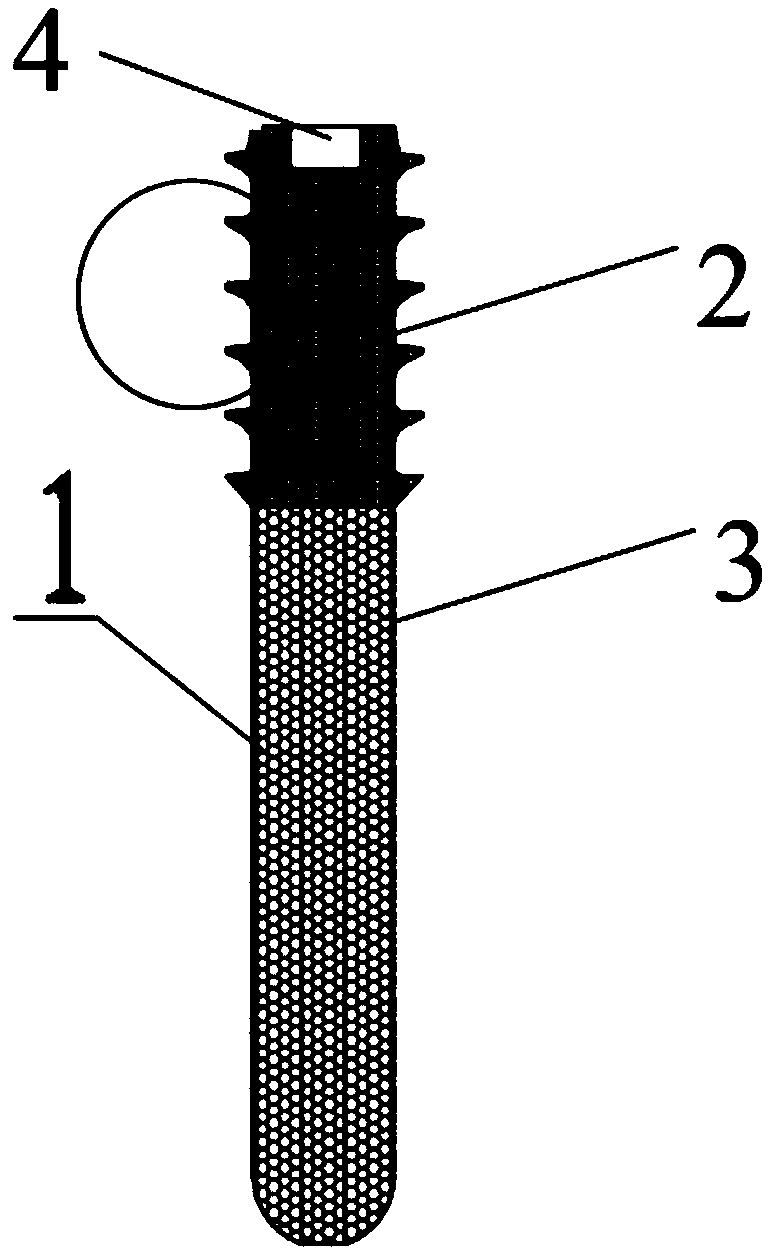

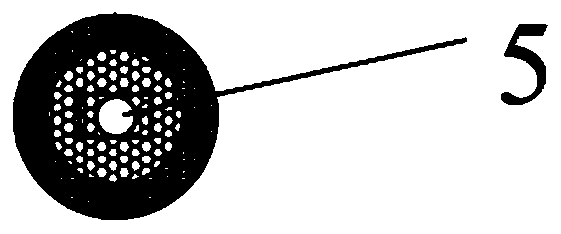

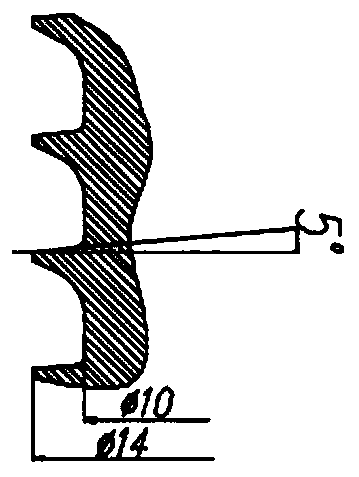

[0024] Such as Figure 1-3 As shown, the tantalum rod 1 includes a threaded portion 2 and a multi-stage hole portion 3, wherein the threaded portion 2 and the multi-stage hole portion 3 are provided with a through hole 5 that penetrates up and down, and the diameter of the through hole is φ3mm. The setting of the through hole Conducive to continuous decompression during and after surgery, the installation of the tantalum rod can be screwed in and positioned along the positioning pin through the through hole; moreover, after the tantalum rod is screwed in, the guide pin can be easily taken out from the through hole; A well-filled bone tissue can also be injected through the through hole through the feeder, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com