Hydrogen fuel battery pack of fuel battery vehicle and radiator

A fuel cell stack, fuel cell technology, applied in the direction of fuel cell heat exchange, fuel cell, fuel cell additives, etc., can solve the problems of electric vehicle performance gap, affecting battery life, unsatisfactory, etc., to improve performance and operational safety, increased reliability and consistency, and reduced waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

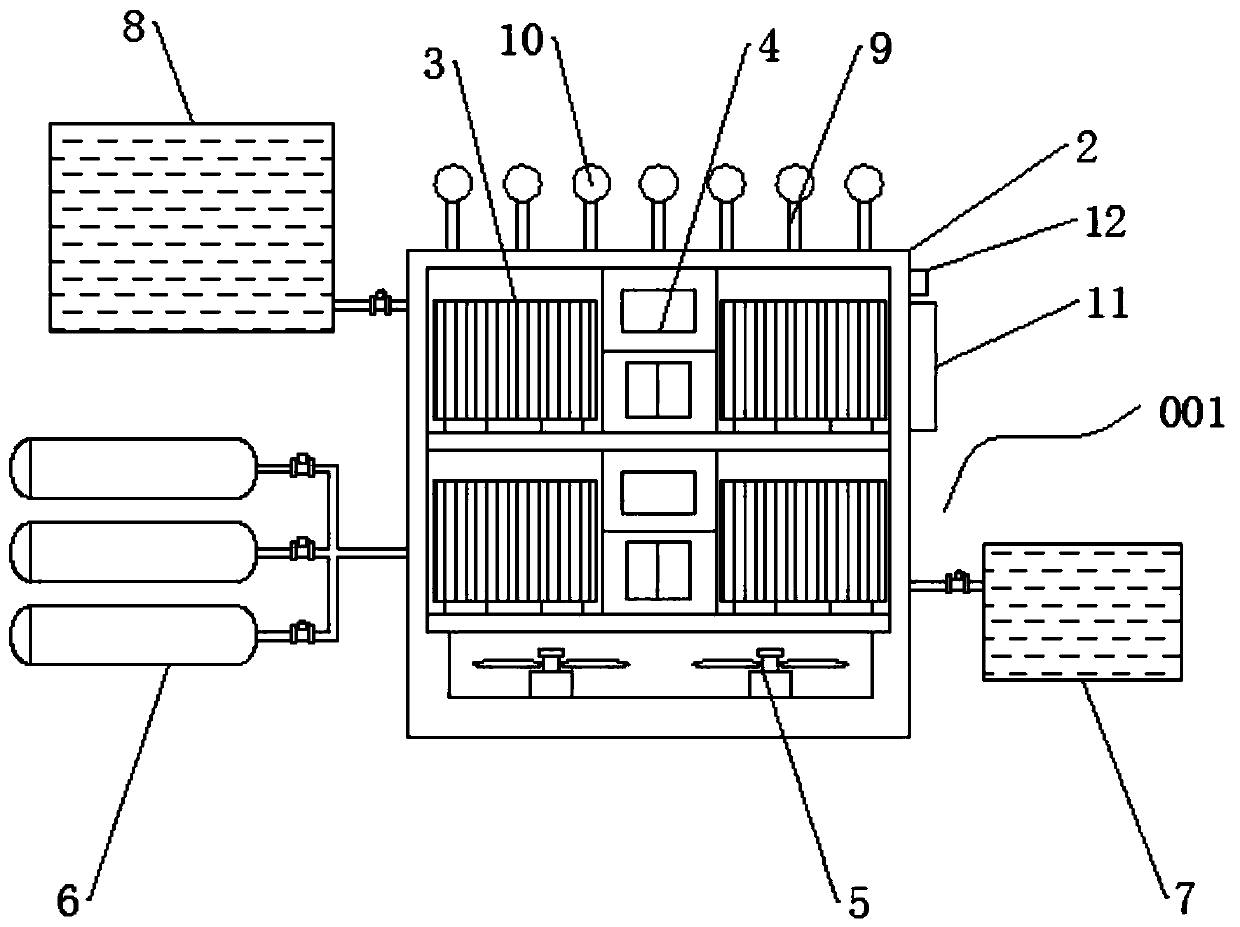

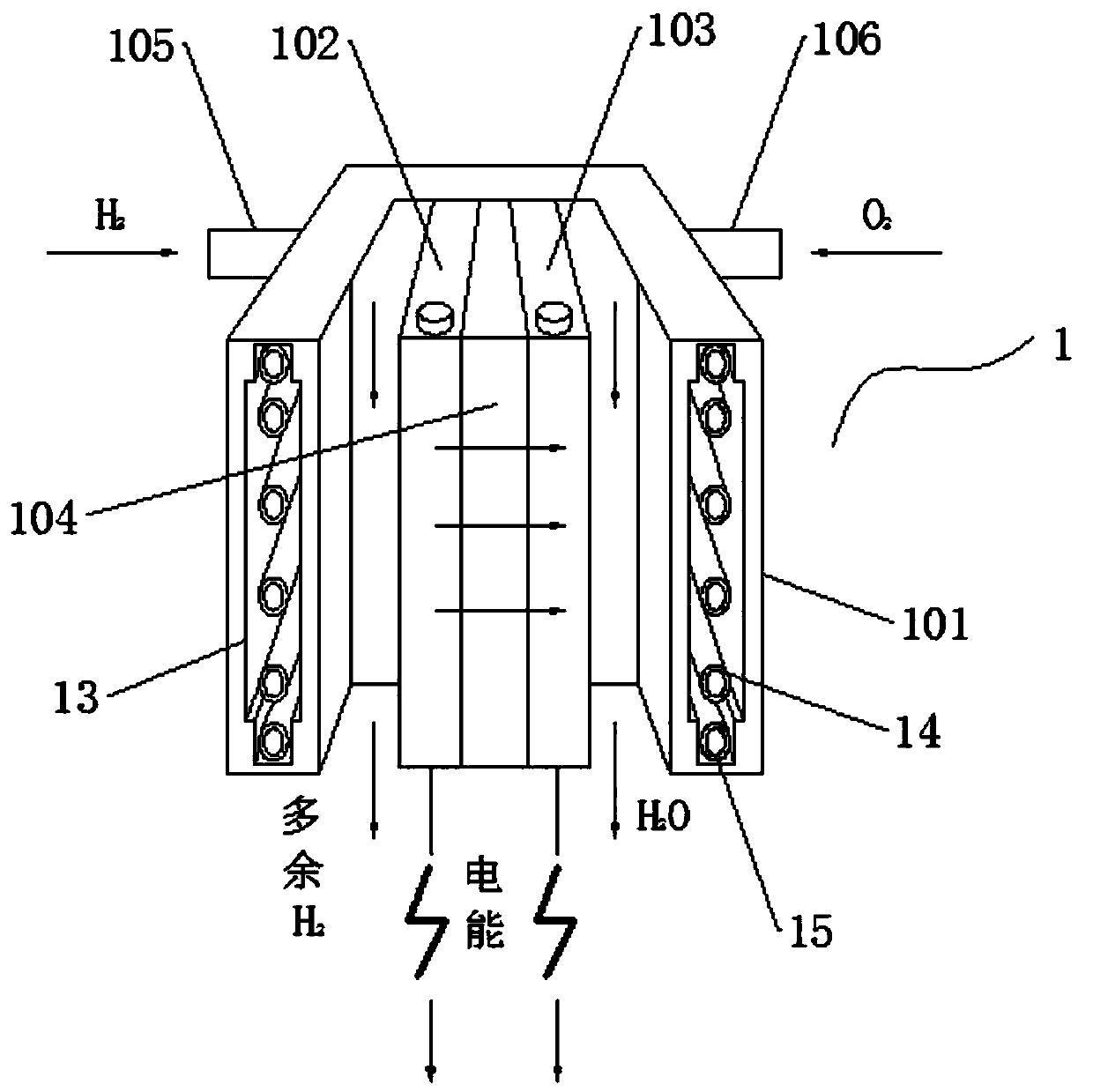

[0042] see figure 1 , a fuel cell vehicle hydrogen fuel cell stack and cooling device, including a fuel cell body 001, a high-pressure hydrogen tank 6 and an air compressor, the fuel cell body 001 includes a mounting shell 2 and a plurality of battery packs 3, and the mounting shell 2 is fixedly connected There is a pair of partitions, and a pair of partitions divide the installation shell 2 into two battery pack placement cavities and a wind cooling cavity, and the wind cooling cavity is located at the lower end of the installation shell 2, and the installation shell 2 is connected with a wide surface cooling The mechanism is used to dissipate the heat of the installation shell 2 as a whole. The wide-area heat dissipation mechanism includes a speed-regulating fan 5 and a fast heat dissipation column 9. A pair of speed-regulating fans 5 are installed in the wind cooling chamber, and a plurality of fast heat dissipation columns 9 are evenly distributed on the installation shell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com