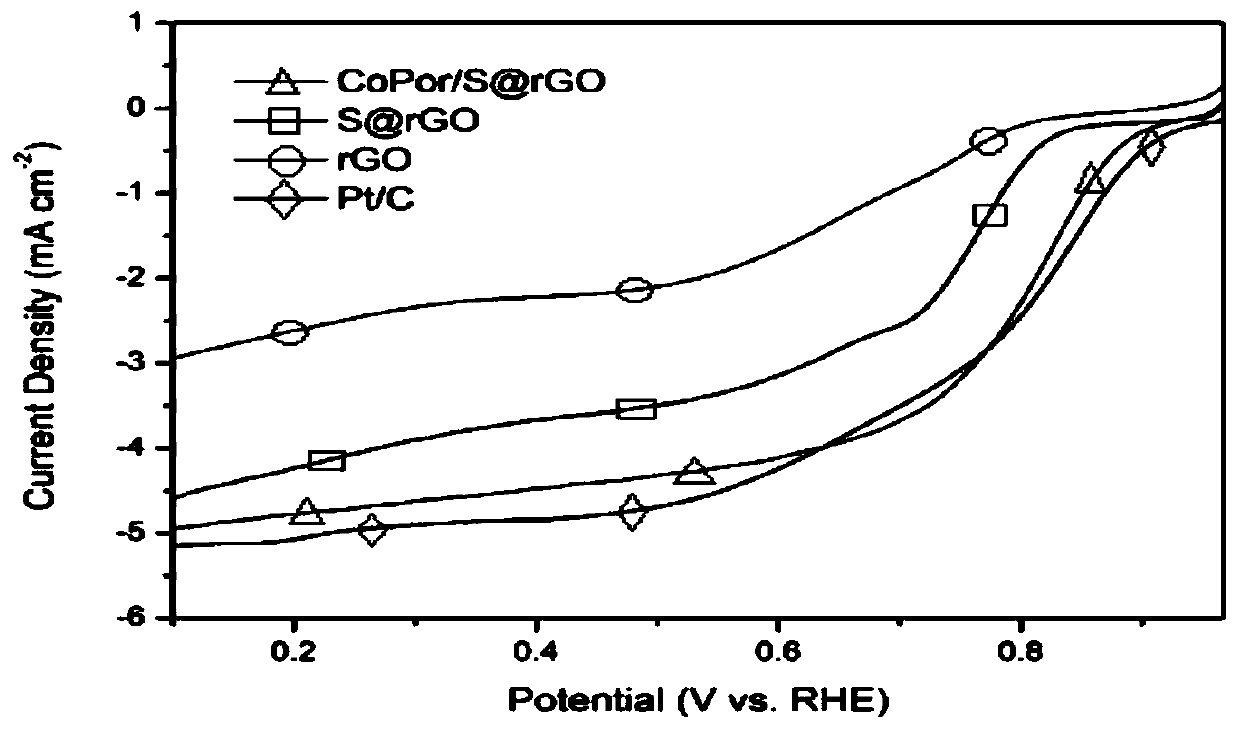

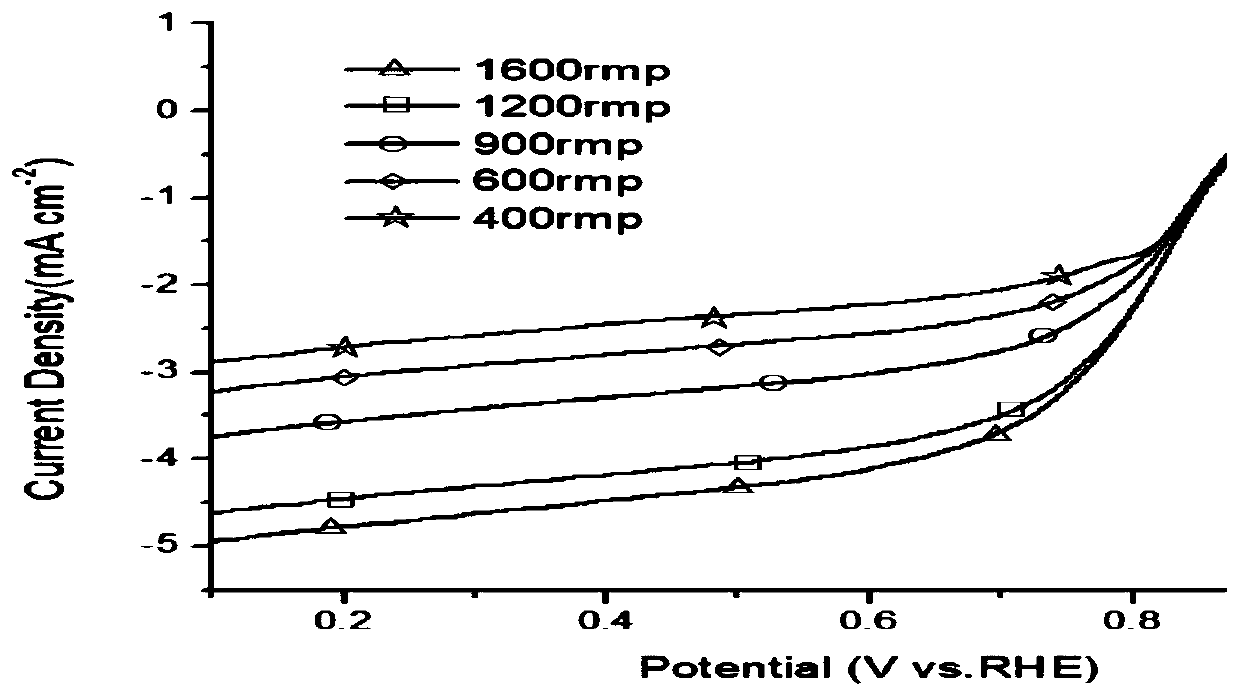

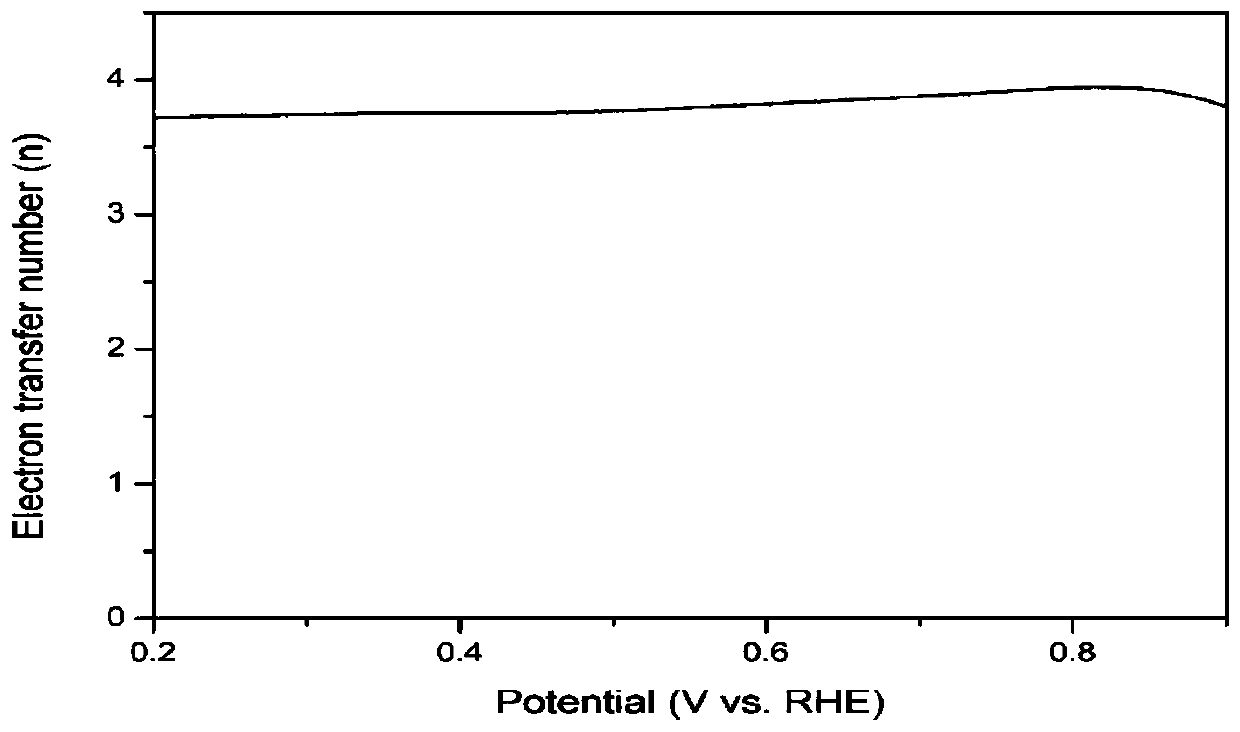

Preparation method and application of metalloporphyrin-modified sulfur-doped reduced graphene oxide electrocatalyst

A technology of metalloporphyrin and electrocatalyst, which is applied in the direction of fuel cell half-cells and primary battery half-cells, circuits, electrical components, etc., to achieve the effects of reducing overpotential, low cost, and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Add 0.5g of graphene oxide into 30ml of tetrahydrofuran and ultrasonically treat it for 10 minutes, then add 1.0g of sodium carbonate and stir at room temperature for 2 hours, then add 1.0g of p-toluenesulfonyl chloride and stir at 60°C for 8 hours, the reaction is complete After cooling to room temperature, the solvent was removed by rotary evaporation under reduced pressure, washed with deionized water, centrifuged after washing, dried in a drying oven at 60°C, and then continued to be heated in a tube atmosphere furnace at a rate of 5°C / min under the protection of an inert gas. Heating rate, heating up to 900°C, and calcining at 900°C for 2 hours to obtain 0.25g of sulfur-doped reduced graphene oxide; (2) Take 50mg m-tetrakis(4-methylphenyl)porphine, 70mg Add cobalt to 80ml of N,N-dimethylformamide, heat and reflux at 120°C for 8 hours, and cool to room temperature to obtain a cobalt porphyrin solution; (3) Take 0.2g of sulfur-doped reduced graphene oxide and add ...

Embodiment 2

[0032] (1) Add 0.5g of graphene oxide to 30ml of N,N-dimethylformamide and sonicate for 30 minutes, then add 1.5g of potassium phosphate and stir at room temperature for 1 hour, then add 2.0g of phenylsulfonyl chloride at 80°C Stir under low temperature for 12 hours, cool to room temperature after the reaction is completed, remove the solvent by rotary evaporation under reduced pressure, wash with methanol solution, centrifuge after washing, dry in a drying oven at 60°C, and then continue to be heated in a tubular atmosphere furnace under the protection of an inert gas. With a heating rate of 3°C / min, the temperature was raised to 800°C, and calcined at 800°C for 1 hour to obtain 0.23g of sulfur-doped reduced graphene oxide; 1. Add 50mg ferric chloride hexahydrate into 200ml 1,4-dioxane, heat and reflux at 100°C for 10 hours, and cool to room temperature to obtain iron porphyrin solution; (3) Take 0.2g sulfur-doped reduced graphene oxide and add into 200ml of iron porphyrin so...

Embodiment 3

[0034](1) Add 0.5g of graphene oxide into 30ml of toluene and ultrasonically treat it for 40 minutes, then add 2.0g of potassium hydroxide and stir at room temperature for 4 hours, then add 3.0g of benzylsulfonyl chloride and stir at 100°C for 10 hours. Cool to room temperature after completion, remove the solvent by rotary evaporation under reduced pressure, wash with methanol solution, centrifuge after washing, dry in a drying oven at 60°C, and then continue to heat in a tube atmosphere furnace at a rate of 10°C / min under the protection of an inert gas. Heating rate, heating up to 600°C, and calcining at 600°C for 4 hours to obtain 0.22g of sulfur-doped reduced graphene oxide; Nickel was added to 140ml of tetrahydrofuran, heated to reflux at 80°C for 12 hours, and cooled to room temperature to obtain a nickel porphyrin solution; (3) 0.2g of sulfur-doped reduced graphene oxide was added to 140ml of nickel porphyrin solution and ultrasonically treated for 40 minutes, Then the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com