Tunnel waterproof layer, model board trolley and construction method

A technology of formwork trolley and construction method, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of reducing the bearing capacity of secondary lining structures, low construction efficiency, and reducing waterproof performance, and achieves the improvement of secondary lining pouring Quality, reduce construction costs, improve the effect of waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

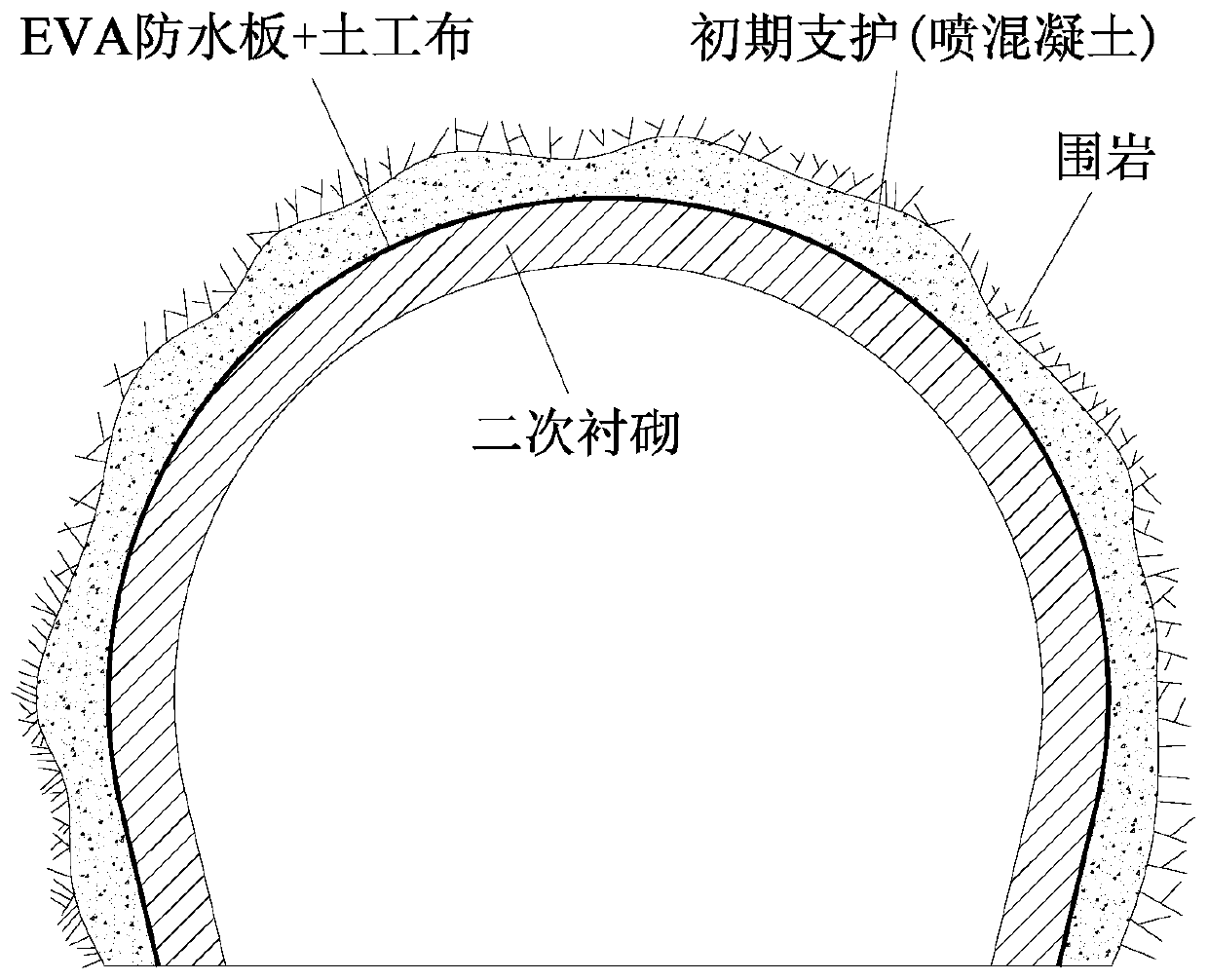

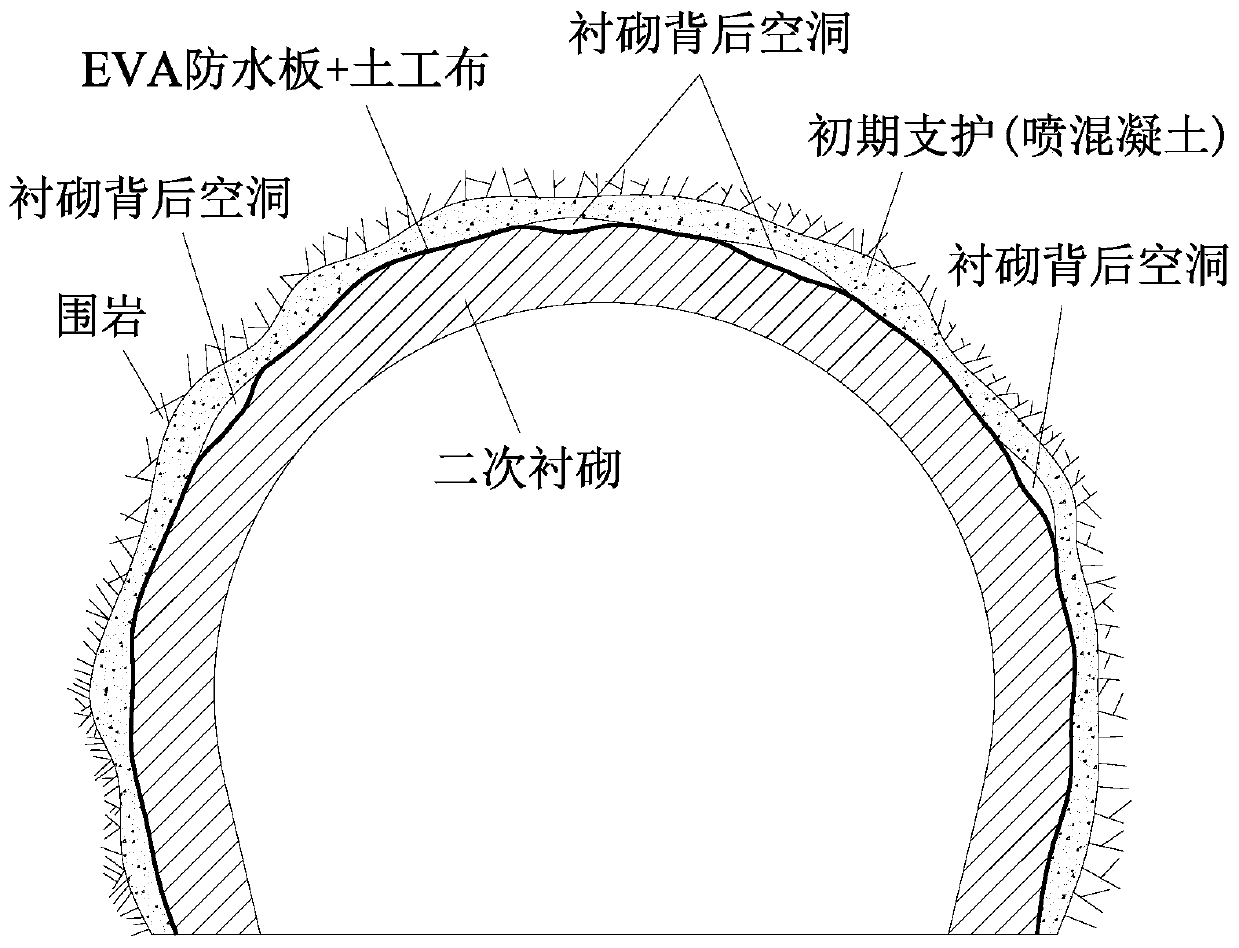

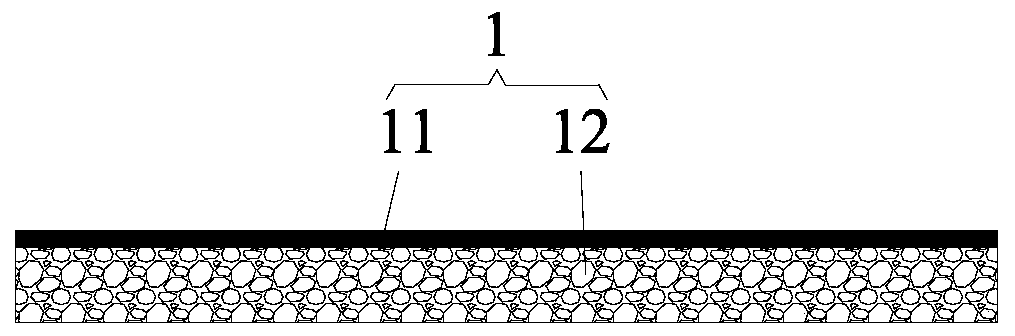

[0087] Such as Figure 3-4 As shown, a tunnel waterproof layer 1 according to the present invention includes a waterproof board 11 and a polyethylene foam board 12 .

[0088] The side of the EVA waterproof board 11 is bonded to the side of the foam board 12 with high porosity, the thickness of the EVA waterproof board 11 is 0.8 mm to 1.5 mm, the thickness of the foam board 12 is 2 mm to 4 mm, and the waterproof layer 1 The width is greater than or equal to 6m, and the preferred width in this embodiment is 6m to 9m; when installed, the EVA waterproof board 11 is used to face the inner side of the tunnel, and the foam board 12 is used to face the side of the surrounding rock.

[0089] Using the tunnel waterproof layer 1 described in the present invention can greatly improve the waterproof performance of the tunnel structure, greatly improve the quality of the secondary lining pouring, greatly improve the construction efficiency, and reduce the construction cost;

[0090] Greatl...

Embodiment 2

[0095] Such as Figure 3-16 As shown, a formwork trolley for a tunnel waterproof layer 1 according to the present invention includes a vehicle body 2, driving components and an arched formwork capable of adapting to the contour of the tunnel.

[0096] The arch formwork includes a vault formwork 3 , a side wall formwork 4 and a footboard formwork 5 ;

[0097] The top of the car body 2 is provided with the first telescopic part 31, and the top end of the first telescopic part 31 is hinged on the inner side of the vault formwork 3, and the two sides of the vault formwork 3 are respectively hinged on the side wall formwork 4. side, the lower side of the side wall template 4 is hinged to the footer template 5, and the side of the car body 2 is hinged to the second telescopic part 41, the third telescopic part 42 and the fourth telescopic part 51, so The other end of the second telescopic part 41 is hinged on the inside of the side wall template 4, the third telescopic part 42 is l...

Embodiment 3

[0106] Such as Figure 3-16 As shown, the construction method of a tunnel waterproof layer 1 according to the present invention uses the formwork trolley of the tunnel waterproof layer 1 as described in Embodiment 2, and the construction method comprises the following steps:

[0107] ① if Figure 6 As shown, the tunnel excavation and initial support shotcrete are completed and the design strength is reached. It should be noted that the thickness of the shotcrete can reach the design thickness, and it is not necessary to spray to the outer contour of the lining.

[0108] ② Start the driving part connected to the arch formwork, so that the arch formwork shrinks radially along the tunnel, so as to increase the working space between the arch formwork and shotcrete;

[0109] Specifically, such as Figure 7 As shown, the contraction of the first telescopic part 31 drives the vault formwork 3 to descend, and both the second telescopic part 41 and the third telescopic part 42 contra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com