Concrete joint waterproof construction technology and construction device thereof

A technology of construction technology and construction device, which is applied in the field of concrete joint water-stop construction technology and its construction device, can solve the problems of poor waterproof ability of concrete joints, short maintenance time of waterproof ability, and troublesome project put into use, etc., and achieve structural Simple, low construction difficulty, and the effect of reducing construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

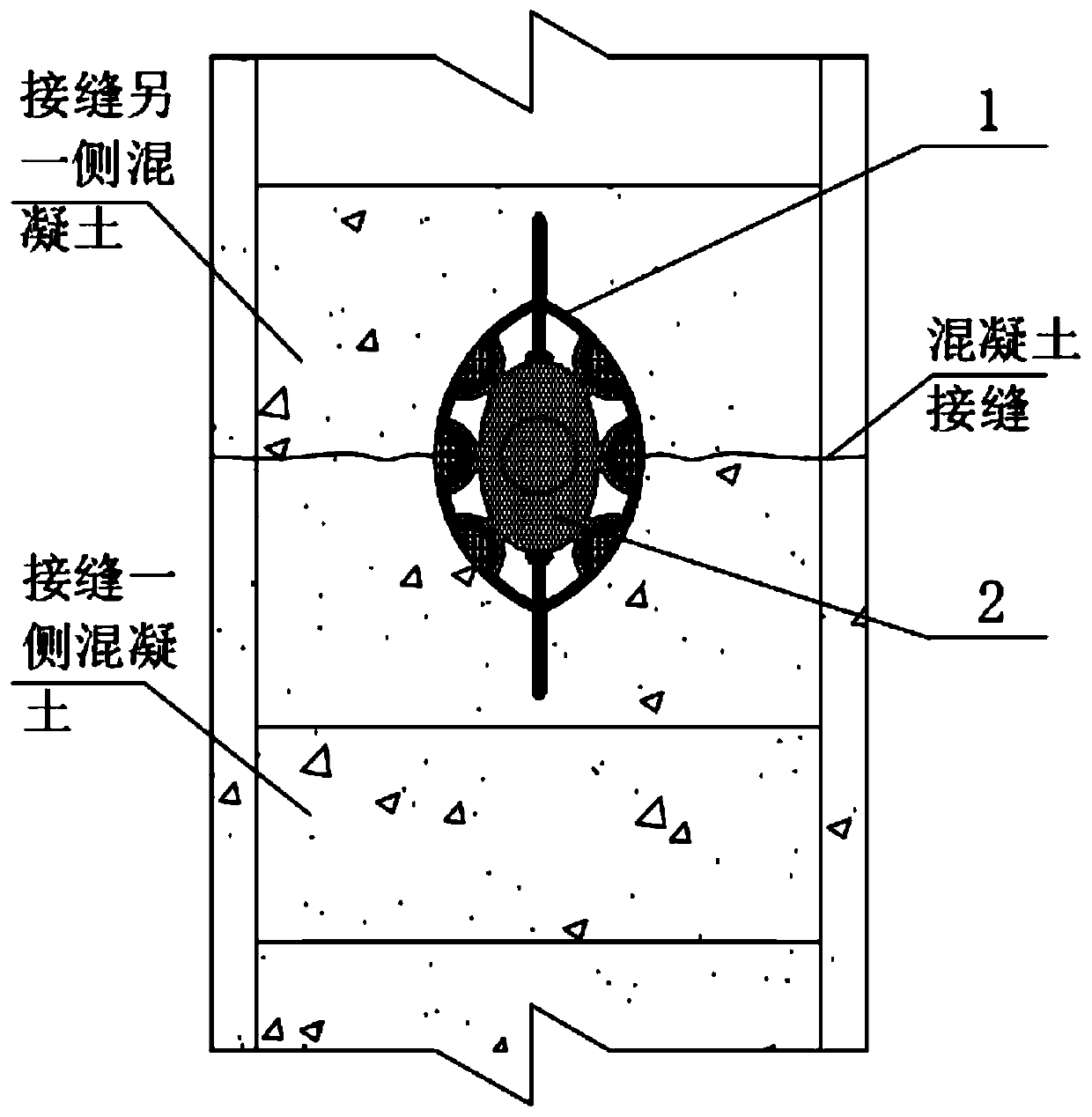

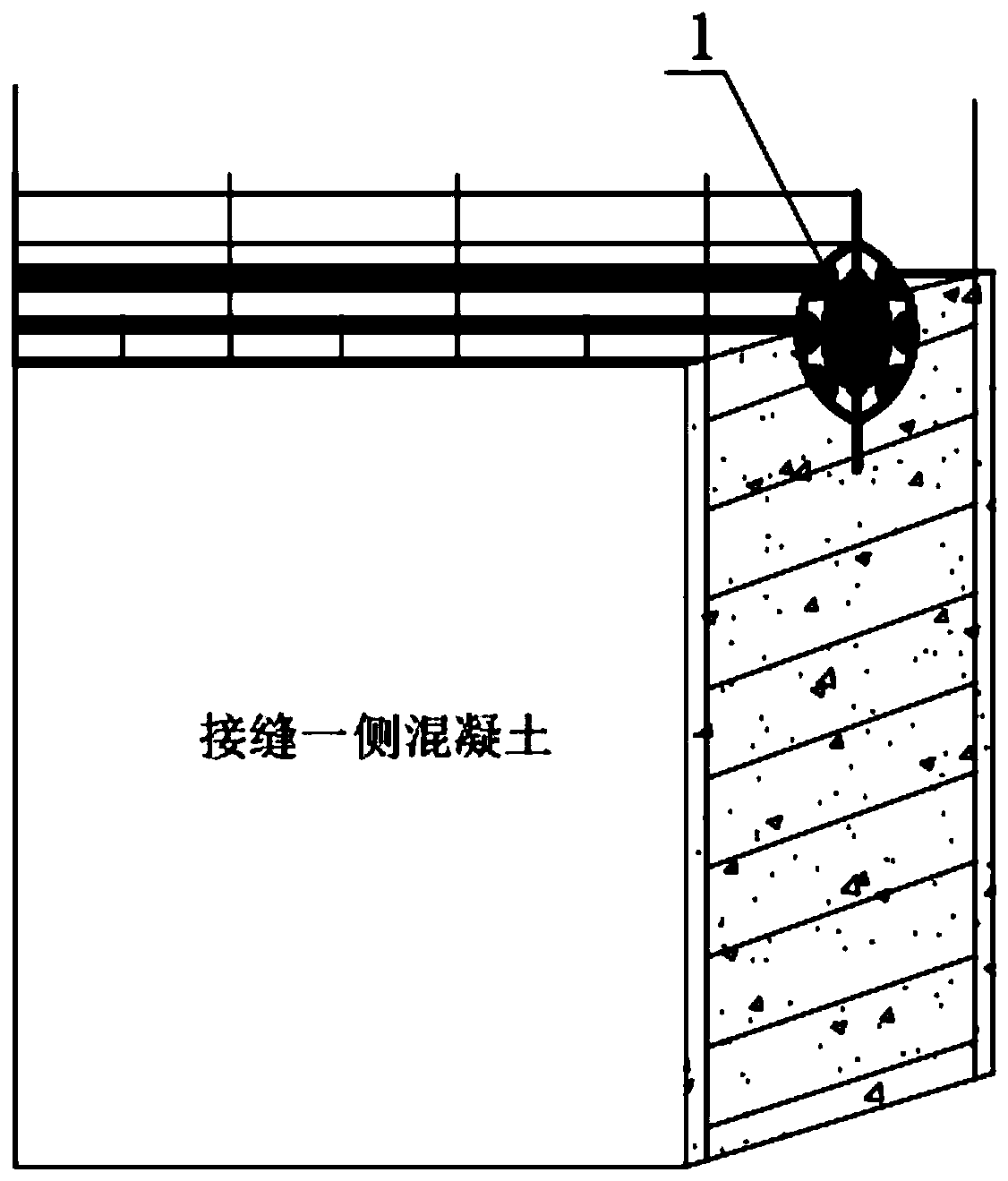

[0048] A concrete joint waterproof construction technology, with reference to Figure 1-2 and 10-11, including the following steps:

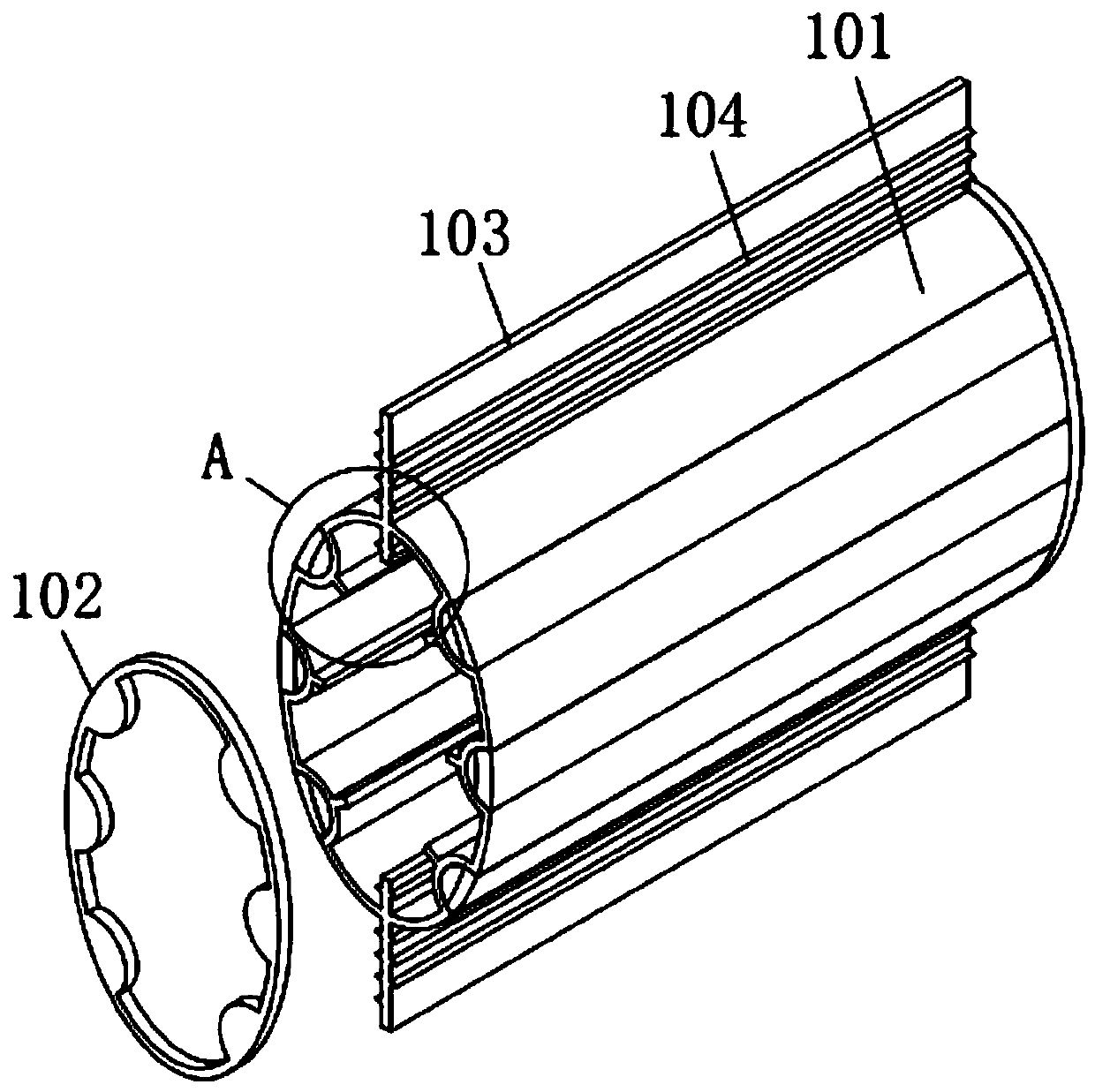

[0049] Step 1. Prepare the water-stop structure 1, the water-stop structure 1 is composed of an oval steel cylinder 101 with open structures at both ends, two end cover plates 102 welded on both ends of the oval steel cylinder 101 and symmetrically welded The elliptical steel cylinder 101 is composed of two steel plate ribs 103 extending outward along the long axis of the ellipse. The body of the elliptical steel cylinder 101 is provided with a number of concave arc grooves 105. The arc-shaped grooves 105 are arranged symmetrically with respect to the ellipse major axis of the oval-shaped steel cylinder 101, and the inside of each arc-shaped groove 105 is filled with a foam layer 107 and a waterproof layer 108 sequentially from the inside to the outside;

[0050] Step 2: Pre-embed the steel plate rib 103 of the prepared water-stop structure 1 a...

Embodiment 2

[0074] The difference from Example 1 is that the surface of the motor 2033 is also provided with a protective layer, and the protective layer is prepared by the following method:

[0075] Take the following raw materials and weigh them by weight: 16-24 parts of epoxy resin, 10-14 parts of calcium carbonate powder, 20-26 parts of ceramic microbeads, 14-18 parts of phenolic resin, 2-4 parts of alcohol ester twelve, three 2-4 parts of ethanolamine, 1-3 parts of emulsified silicone oil and 30-50 parts of water;

[0076] S1. Add the weighed alcohol ester dodecane, triethanolamine, emulsified silicone oil and water into the mixer and stir for 20-35min at a stirring speed of 600-700r / min to prepare a mixed solution;

[0077] S2. Grinding epoxy resin, calcium carbonate powder, and phenolic resin in a ball mill until the particle diameter of the material is not greater than 100nm, so as to obtain a mixed powder material;

[0078] S3. Add the mixed solution prepared in step S1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com