Sulfonated humic acid fracturing fluid and preparation method thereof

A technology of sulfonated humic acid and fracturing fluid, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of fast dehydration, poor salt resistance, low sand-carrying performance, etc., and improve viscoelasticity , water retention improvement, considerable effect of salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

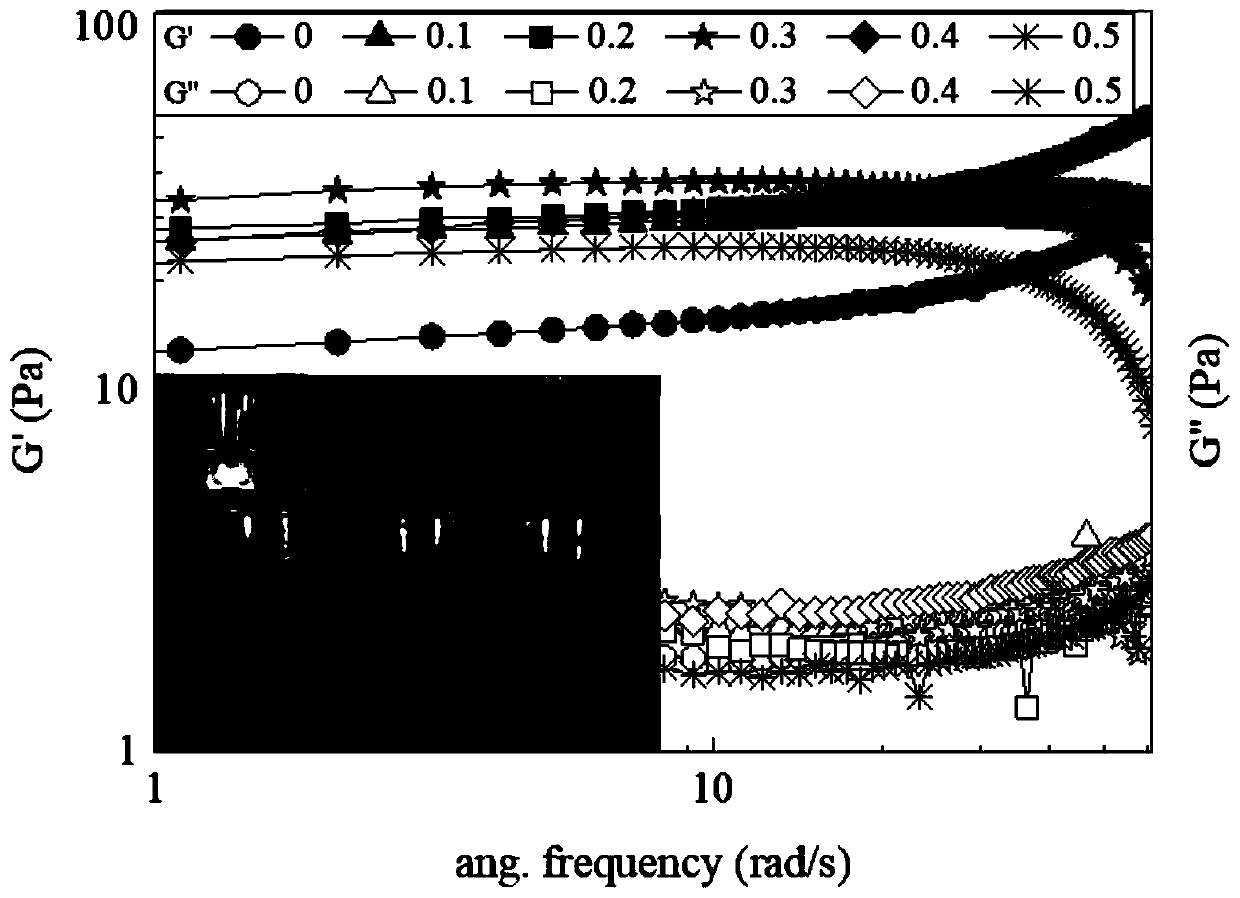

[0022] The invention discloses a method for preparing sulfonated humic acid fracturing fluid, wherein the sulfonated humic acid fracturing fluid is cross-linked by sulfonated humic acid and carboxymethyl guar gum through an organic zirconium crosslinking agent; The concentration of carboxymethyl guar gum is 0.5wt%, and the addition of sulfonated humic acid is (0.1-1)% of carboxymethyl guar gum solution quality, and the mass ratio of carboxymethyl guar gum solution and organic zirconium crosslinking agent is 100:1.

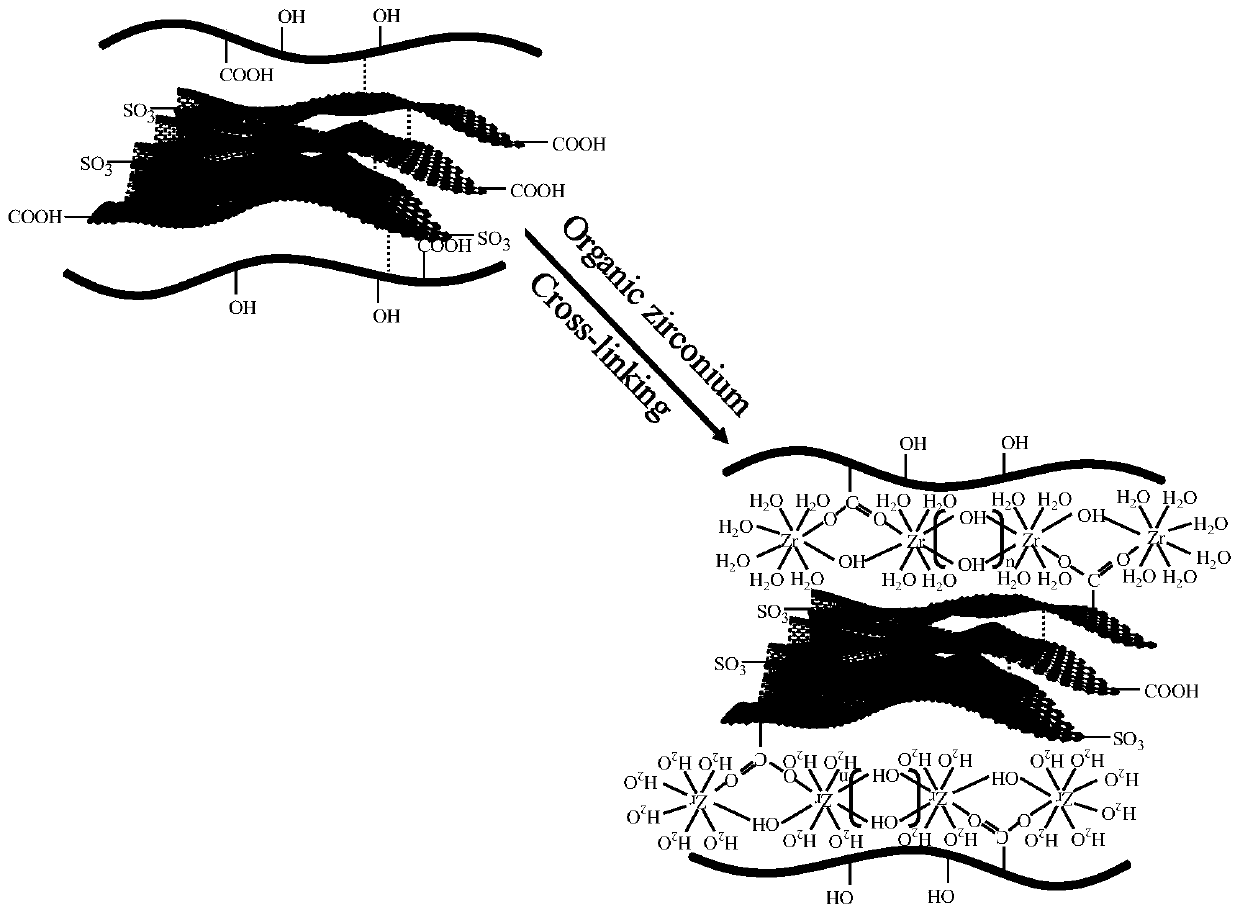

[0023] Principle of the present invention is:

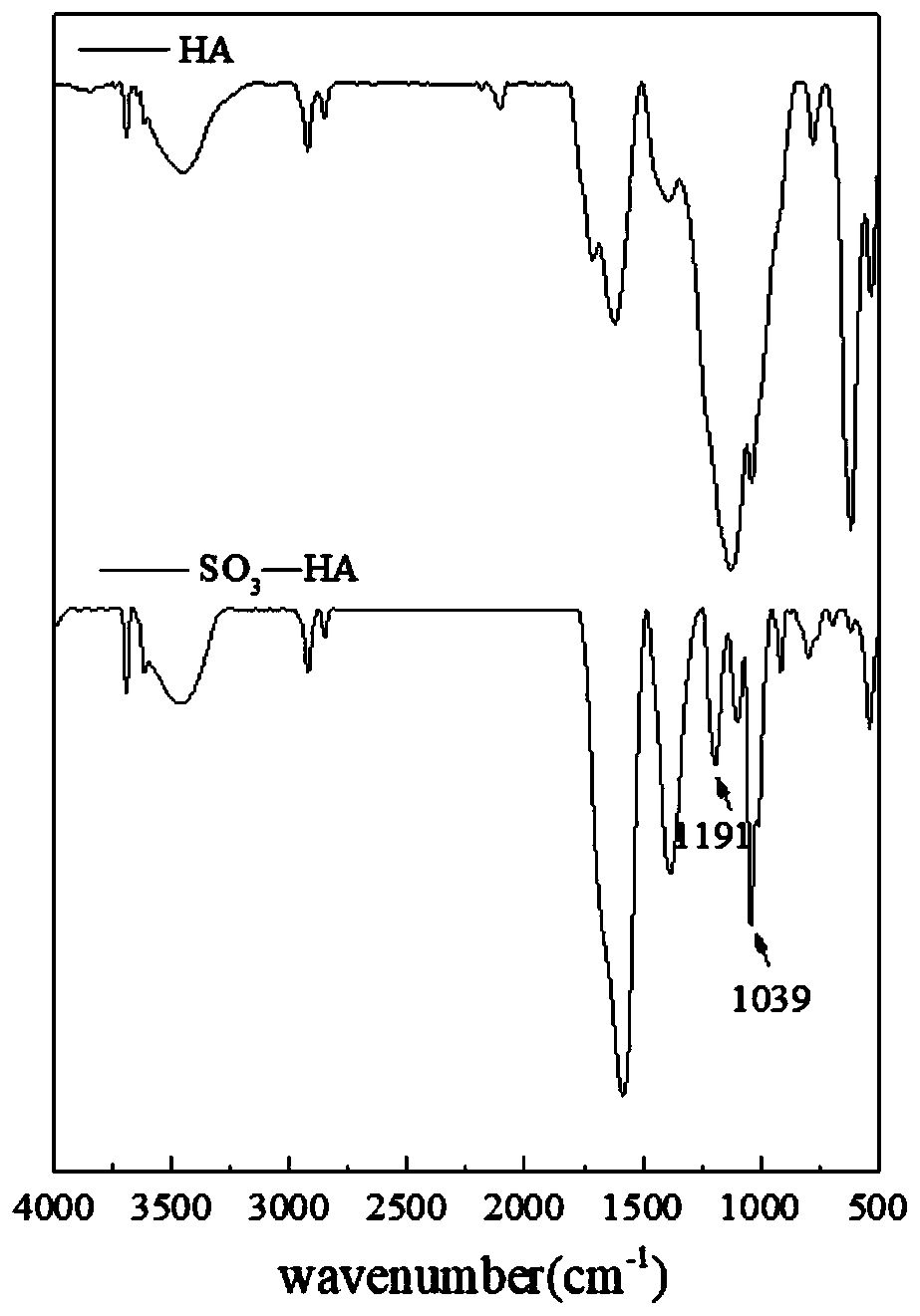

[0024] After cross-linking with organozirconium cross-linking agent, carboxymethyl guar gum has improved gel strength and enhanced sand-carrying ability, but the modified carboxymethyl guar gum has the problem of rapid dehydration after cross-linking with organo-zirconium cross-linking agent . Humic acid is a kind of natural macromolecular aromatic polymer, which is very rich in reserves in my country, has the chara...

Embodiment 1

[0031] Add 3g of sodium hydroxide and 150g of deionized water into a three-necked flask. Heat to 50°C, completely dissolve humic acid in it, and then add 1.6g of sodium sulfite. Heating and stirring continued for 4h, and then dilute hydrochloric acid solution was added dropwise until a brown and black paste precipitated. Finally, the brown-black slurry is purified to obtain sulfonated humic acid. Add deionized water into the three-neck flask, heat to 50°C, dissolve 15g of zirconium oxychloride and 0.01g of ammonium chloride therein, and then add 20g of ethylene glycol and 16g of lactic acid. Afterwards, potassium hydroxide solution was added dropwise until the pH value reached neutrality, and the heating and stirring were continued for 4 hours, and then a colorless and transparent organic zirconium binder was obtained. Configure carboxymethyl guar gum solution, the configuration concentration is 0.5wt%, static swelling, sulfonated humic acid is added in the carboxymethyl gua...

Embodiment 2

[0034] Add 3g of sodium hydroxide and 150g of deionized water into a three-necked flask. Heat to 50°C, completely dissolve humic acid in it, and then add 1.6g of sodium sulfite. Heating and stirring continued for 4h, and then dilute hydrochloric acid solution was added dropwise until a brown and black paste precipitated. Finally, the brown-black slurry is purified to obtain sulfonated humic acid. Add deionized water into the three-neck flask, heat to 50°C, dissolve 15g of zirconium oxychloride and 0.01g of ammonium chloride therein, and then add 20g of ethylene glycol and 16g of lactic acid. Afterwards, potassium hydroxide solution was added dropwise until the pH value reached neutrality, and the heating and stirring were continued for 4 hours, and then a colorless and transparent organic zirconium binder was obtained. Configure carboxymethyl guar gum solution, the configuration concentration is 0.5wt%, static swelling, sulfonated humic acid is added in the carboxymethyl gua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com