Melamine-based porous covalent organic polymer as well as preparation method and application thereof

A covalent organic and melamine technology, applied in chemical instruments and methods, instruments, analytical materials, etc., can solve the problems of difficult large-scale preparation, long synthesis time, high synthesis temperature, etc., achieve good detection effect and sensitivity, simple structure, and easy synthesis The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The synthesis of embodiment 1 porous covalent organic polymer material melamine-COP

[0044] Accurately weigh 1.008g (0.008mol) of melamine and 1.261g (0.006mol) of 4,4'-biphenyldiformaldehyde into a 250ml two-necked flask in turn, add 80ml of dimethyl sulfoxide, fill with nitrogen protection, and store at 120°C Under the condition of reflux, react for 1 day. It was then cooled to room temperature and the solid was filtered off to obtain a porous covalent organic polymer material.

[0045] The obtained porous covalent organic polymer material was repeatedly washed with hot water at 60°C to remove unreacted melamine, and then washed with acetone and tetrahydrofuran for 24 hours after filtration to remove unreacted 4,4'-biphenyl Diformaldehyde. Then filter and dry to obtain melamine-COP.

Embodiment 2

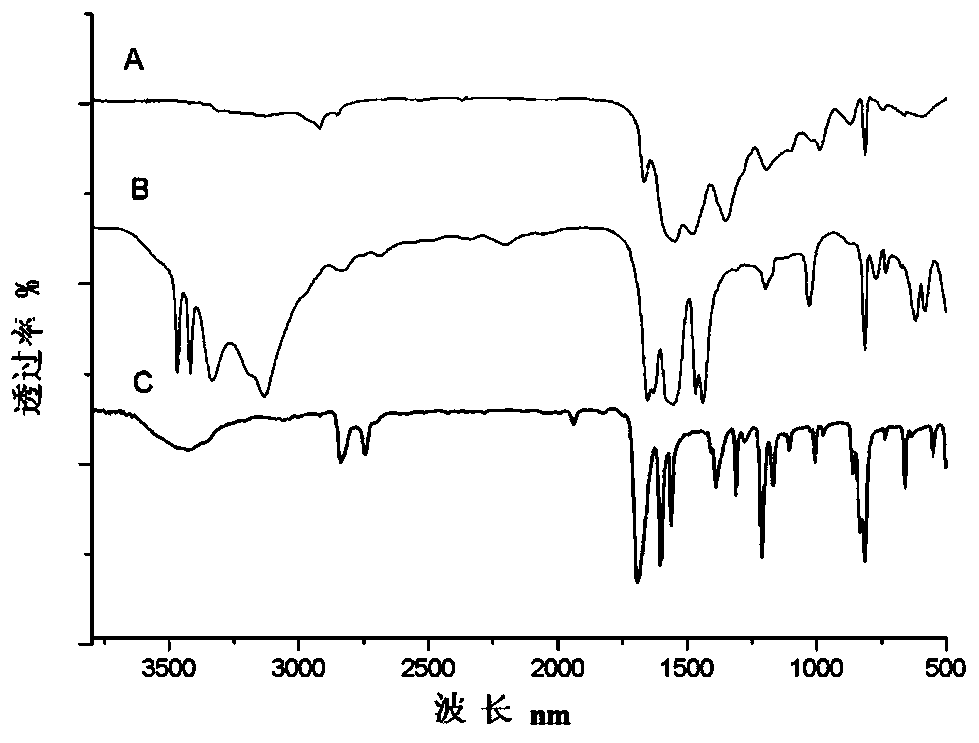

[0047] The melamine-COP that embodiment 1 obtains carries out infrared spectroscopic analysis, and the obtained infrared spectrogram is as follows figure 1 Shown, the infrared absorption spectrum of monomer melamine (melamine, B) is at 3500cm -1The characteristic peak of amino group appears at 4,4'-biphenyldicarbaldehyde (4,4'-Biphenyldicarboxaldehyde, C) at 1670cm -1 The characteristic peak of carbonyl appears at the place, and melamine-COP (A) is in 1360cm -1 The characteristic peak of the amide bond appears at , but the characteristic peak of the two monomers does not appear, indicating that the two monomers participate in the reaction to form a new amide bond-linked COP material.

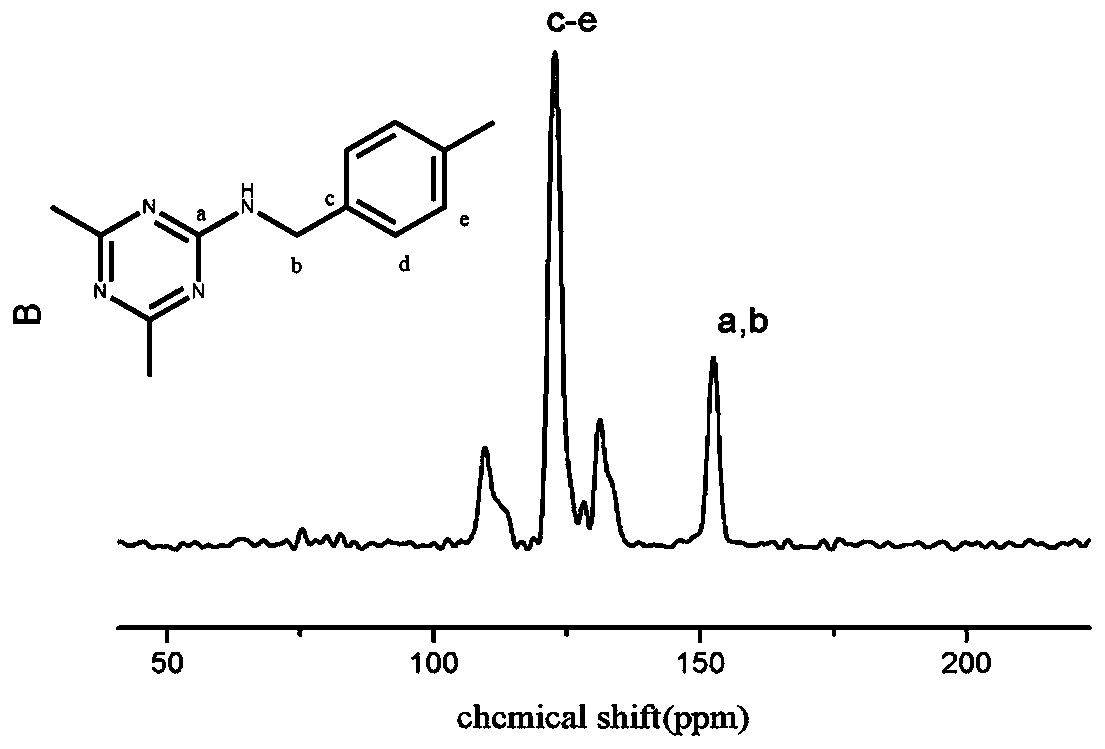

[0048] The melamine-COP that embodiment 1 obtains carries out carbon nuclear magnetic spectrum ( 13 C NMR) analysis, the obtained carbon nuclear magnetic spectrum is as figure 2 As shown, about 166ppm corresponds to the chemical shift of C on the -C=N bond on melamine, about 160ppm correspon...

Embodiment 3

[0050] Carry out the absorption and desorption test of nitrogen to the porous covalent organic polymer material that embodiment 1 obtains, Figure 4 is the pore size distribution diagram of the material, from Figure 4 It can be seen that the material has a uniform pore size, and the pore size distribution is about 1.13nm, which is a microporous material. Figure 5 is the isothermal adsorption-desorption curve of the material, and is the characteristic of the adsorption-desorption curve of a typical microporous material. This also coincides with the fact that the COP material has a uniform pore size.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com