Devolatilization method of nylon 6 melt

A devolatilization and melt technology, applied in the field of nylon materials, can solve problems such as increased melt viscosity, pipe blockage, and molding difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

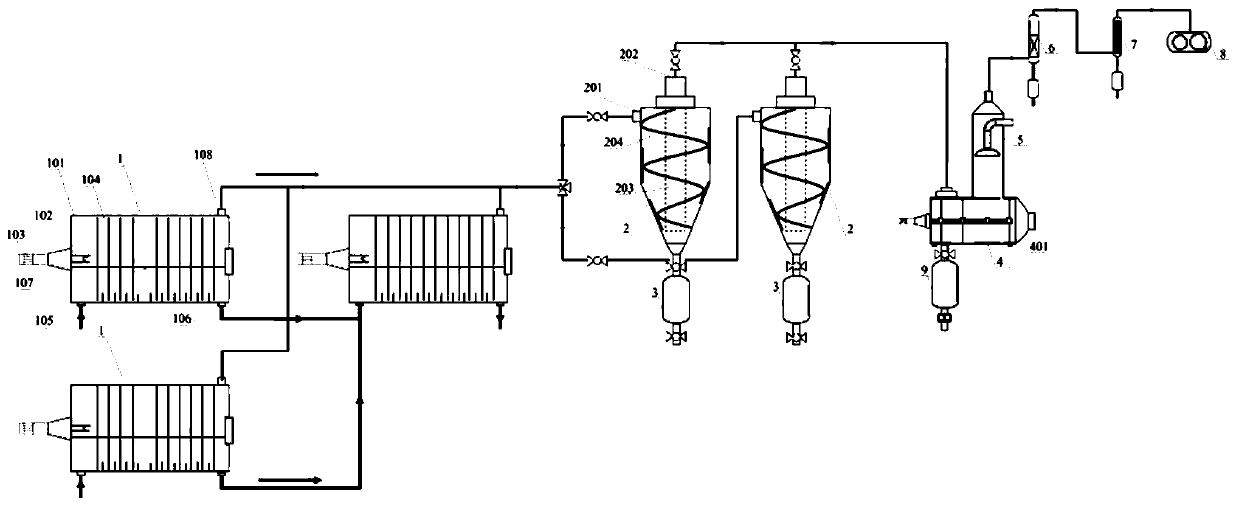

[0083] A method for devolatilization of nylon 6 melt, comprising the following steps:

[0084] 1) The nylon 6 melt and the hot nitrogen with a water content of 0.1wt% are passed through the respective channels into the front-end devolatilization reactor for devolatilization, and most of the hot water extractables in the nylon 6 melt are removed. The hot water extractables are mixed with hot nitrogen to form a gaseous mixture and discharged from the devolatilization reactor. The devolatilized nylon 6 melt is transported to the devolatilization reactor at the rear end for secondary devolatilization without nitrogen gas. The resulting Nylon 6 melt and gaseous mixture are respectively discharged from the devolatilization reactor. Wherein, the absolute pressure in the devolatilization reactor located at the front end is 500 Pa, the temperature is 240°C, and the residence time of nylon 6 melt in the devolatilization reactor is 0.5h; The absolute pressure is below 500Pa, the tempera...

Embodiment 2

[0095] A method for devolatilization of nylon 6 melt, comprising the following steps:

[0096] 1) The nylon 6 melt and hot nitrogen with a water content of 10wt% are passed through their respective channels into the front-end devolatilization reactors (two in parallel) for devolatilization, and most of the hot water in the nylon 6 melt can be extracted The extractables are removed, the hot water extractables are mixed with hot nitrogen to become a gaseous mixture and discharged from the devolatilization reactor, and the devolatilized nylon 6 melt is transported to the devolatilization reactor at the rear end (located in series at the rear end) for further processing The secondary devolatilization without nitrogen, the nylon 6 melt and the gaseous mixture generated after the second devolatilization are respectively discharged from the devolatilization reactor. Wherein, the absolute pressure in the devolatilization reactor located at the front end is 1000 Pa, the temperature is ...

Embodiment 3

[0107] The difference between embodiment 3 and embodiment 1 is:

[0108] (1) The diameter of the air holes on the devolatilization plate is 1mm;

[0109] (2) The water content of the hot nitrogen is 0.5wt%;

[0110] (3) The absolute pressure of the devolatilization reactor at the front end is 800Pa, the temperature is 260°C, and the residence time is 1.5h. The absolute pressure of the back-end devolatilization reactor is below 500Pa, the temperature is 260°C, and the residence time is 20min.

[0111] (4) The working temperature of the high boiling point component removal tower is 180°C, the rotation speed of the spiral blade is 80r / min, and the temperature of the pipeline from the high boiling point component removal tower to the low boiling point component removal tower is kept at 90°C.

[0112] (5) The working temperature of the high boiling point component removal tower is 75°C; the spraying medium is caprolactam, and the spraying temperature is 75°C. The temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com