A method for deesterifying water-soluble soybean polysaccharide and its product

A soybean polysaccharide, water-soluble technology, applied in the field of food processing, can solve the problems of slow production speed, high production cost, large-scale industrial production of enzymatic process, and achieve the effect of preventing equipment corrosion and overcoming environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

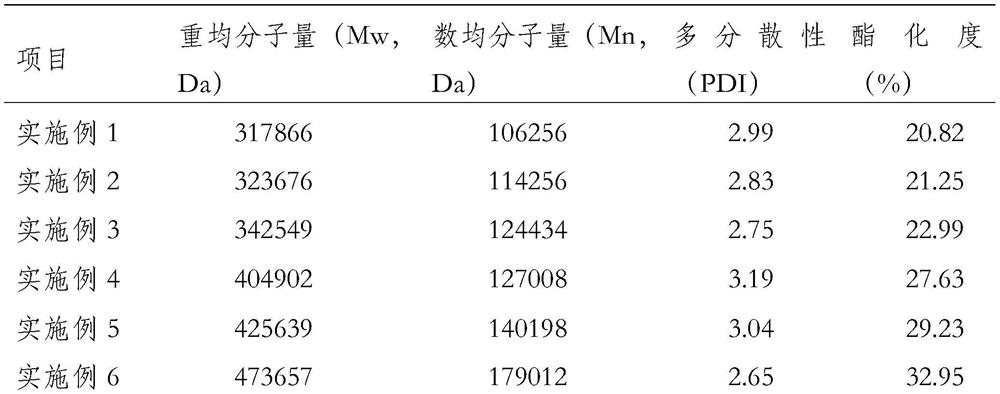

Embodiment 1

[0031] The present embodiment provides a kind of water-soluble soybean polysaccharide (SSPS) deesterification process, adopts following process steps:

[0032] (1) Utilize magnesium nitrate hexahydrate to prepare magnesium nitrate solution, the mass ratio of magnesium nitrate hexahydrate to ultrapure water is 1:80, place the prepared solution under stirring and add ammonia water drop by drop until the solution is turbid, continue Keep stirring for 12-24 hours. Stop stirring and carry out suction filtration. The solid part obtained by suction filtration is roasted at 500°C for 5 hours to obtain a pure white solid, which is ground to powder to obtain the solid base catalyst MgO.

[0033] (2) Preparation of 5% SSPS extract: water-soluble soybean polysaccharide and ultrapure water were mixed according to the mass ratio of 1:20 to prepare a water-soluble soybean polysaccharide solution.

[0034] (3) Put the catalyst MgO in the SSPS solution to form a mixture and continue to stir t...

Embodiment 2

[0037] The present embodiment provides a kind of water-soluble soybean polysaccharide (SSPS) deesterification process, adopts following process steps:

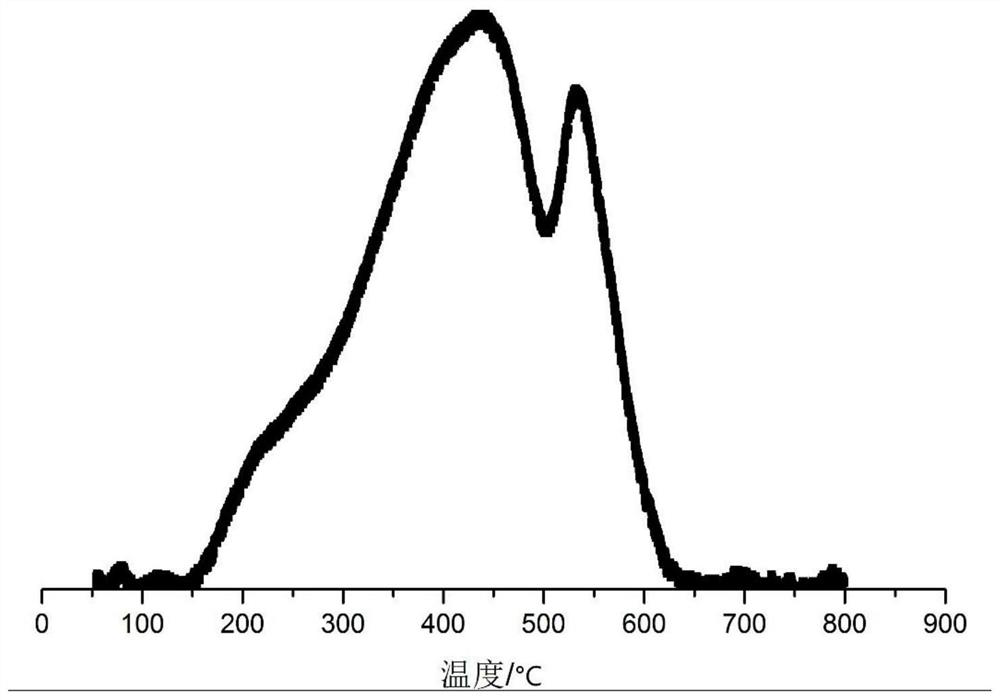

[0038] (1) Utilize magnesium nitrate hexahydrate to prepare magnesium nitrate solution, the mass ratio of magnesium nitrate hexahydrate to ultrapure water is 1:80, place the prepared solution under stirring and add ammonia water drop by drop until the solution is turbid, continue Keep stirring for 12-24 hours; stop stirring and carry out suction filtration, and put the solid part obtained by suction filtration at 500°C for 5 hours to obtain a pure white solid, and grind it to powder to obtain the solid base catalyst MgO, the CO of MgO 2 - TPD test picture see figure 1 , CO 2 The total adsorption capacity is 0.352mmol / g.

[0039] (2) Preparation of 5% SSPS extract: water-soluble soybean polysaccharide and ultrapure water were mixed according to the mass ratio of 1:20 to prepare a water-soluble soybean polysaccharide solution....

Embodiment 3

[0043] The present embodiment provides a kind of water-soluble soybean polysaccharide (SSPS) deesterification process, adopts following process steps:

[0044] (1) Utilize magnesium nitrate hexahydrate to prepare magnesium nitrate solution, the mass ratio of magnesium nitrate hexahydrate to ultrapure water is 1:80, place the prepared solution under stirring and add ammonia water drop by drop until the solution is turbid, continue Keep stirring for 12-24 hours. Stop stirring and carry out suction filtration. The solid part obtained by suction filtration is roasted at 500°C for 5 hours to obtain a pure white solid, which is ground to powder to obtain the solid base catalyst MgO.

[0045] (2) Preparation of 5% SSPS extract: water-soluble soybean polysaccharide and ultrapure water were mixed according to the mass ratio of 1:20 to prepare a water-soluble soybean polysaccharide solution.

[0046] (3) Put the catalyst MgO in the SSPS solution to form a mixture and continue to stir t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com