Table type edge grinding machine

A sharpening machine and desktop technology, applied in the direction of grinding frame, grinding machine parts, planing machine, etc., can solve the problem that the angle and feed cannot be controlled, it is difficult to keep the turning knife sharpening smoothly, and the turning knife sharpening cannot be guaranteed issues of accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

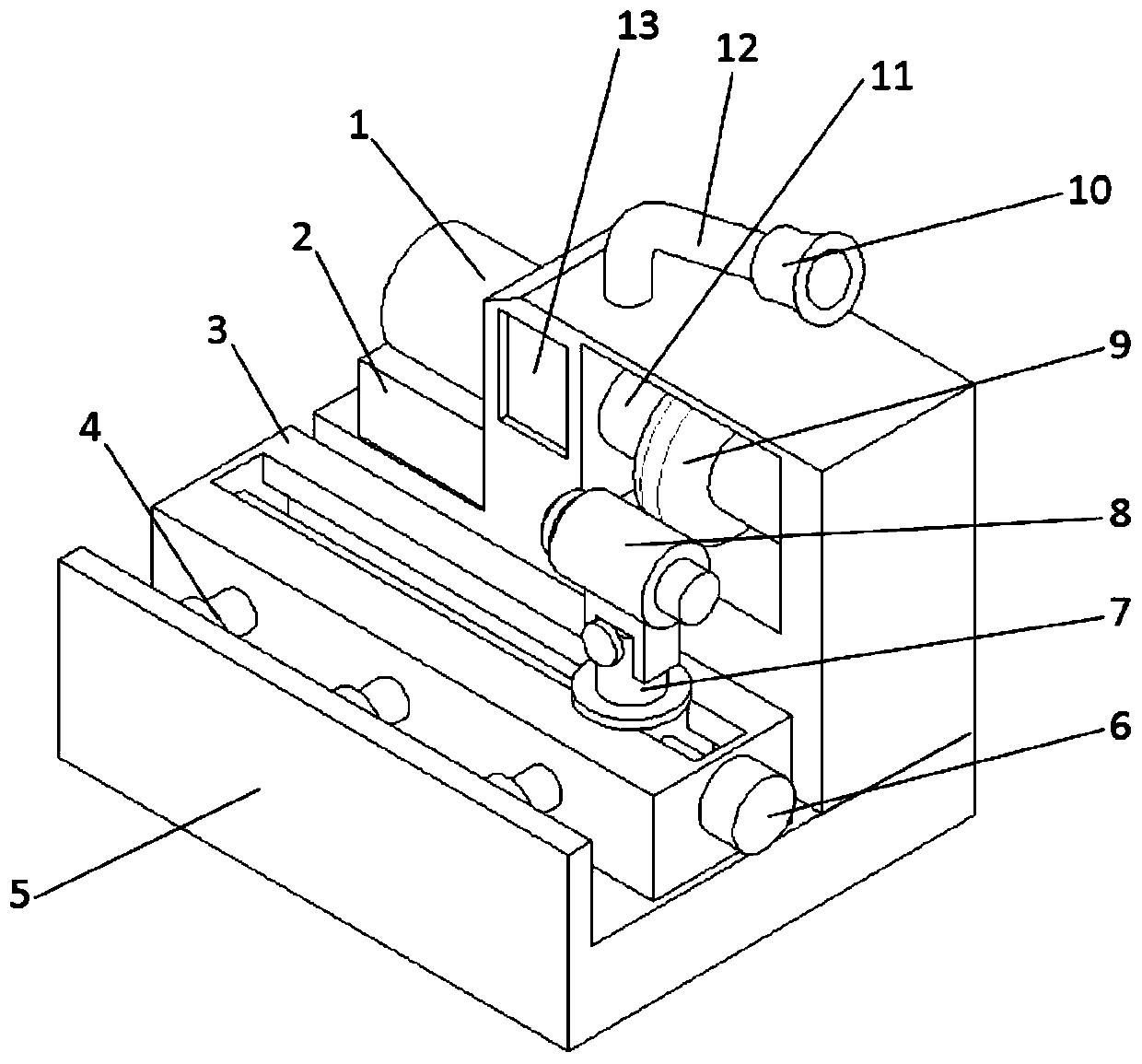

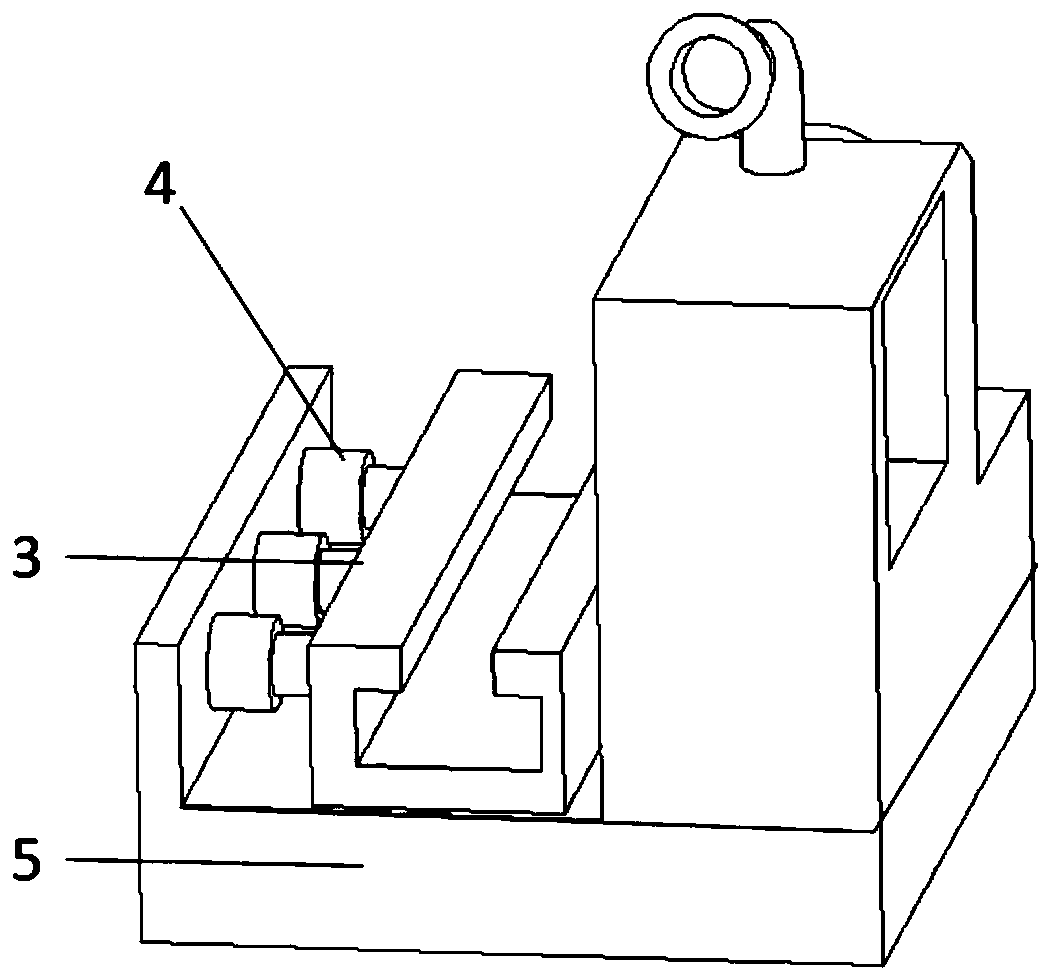

[0027] A desktop sharpener, such as Figure 1-4 As shown, including frame 5, sharpening device, mobile slide table and tool feeding device;

[0028] Sharpening device is arranged on frame 5 side, comprises first driving device and emery wheel 9, and first driving device drives emery wheel 9 to rotate; Offer groove in the middle of frame 5, mobile sliding table is arranged in the groove, and mobile sliding table comprises The translation sliding table 3, the second driving device and the electric telescopic device, the electric telescopic device drives the translation sliding table 3 to radially reciprocate in the groove;

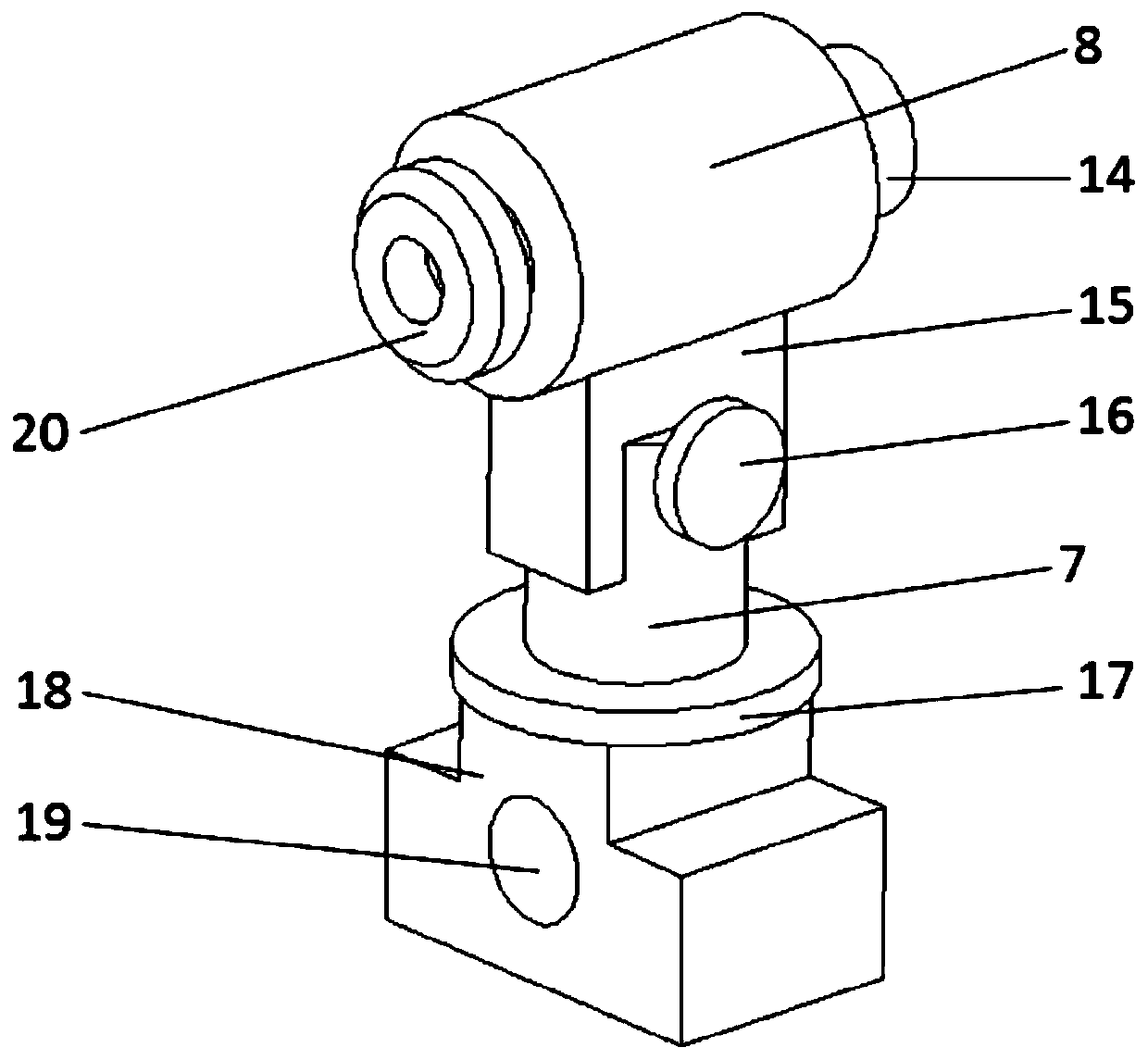

[0029] The tool feed device is arranged on the top of the translation slide table 3, and the second driving device drives the tool feed device to reciprocate along the axial direction of the translation slide table 3; the tool feed device includes a tool holder, a first angle adjustment device, a second angle An adjustment device and a third angle adjustmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com