An industrial steelmaking waste steel slag recovery and reuse treatment equipment and treatment process

A technology for waste steel slag and processing equipment, applied in grain processing and other directions, can solve the problems of large volume, inconsistent shape, waste of time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

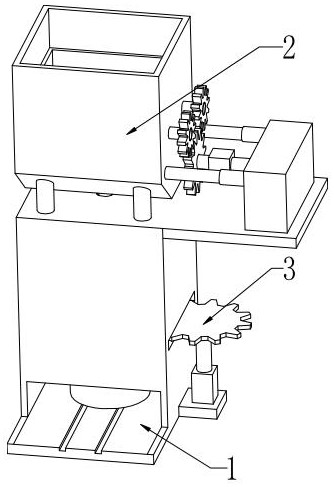

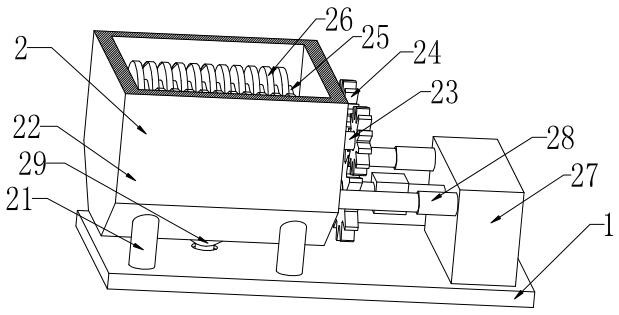

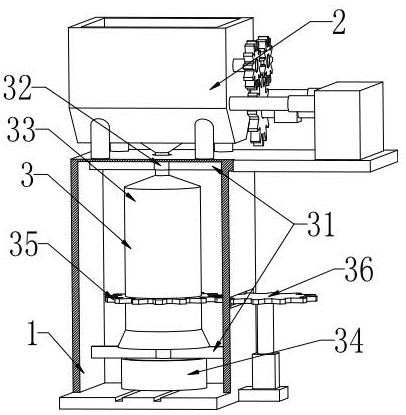

[0032] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 8 , to further elaborate the present invention.

[0033] An industrial steelmaking waste steel slag recovery and reuse processing equipment, including a mounting frame 1, a shredding set 2 and a ball milling set 3, characterized in that: a shredding set 2 is installed on the mounting frame 1, and a ball mill is installed at the lower end of the shredding set 2 Kit 3, Ball Mill Kit 3 is located inside Mount 1, where:

[0034] The shredding set 2 includes a support column 21, a crushing box 22, a central rotating shaft 23, a driven gear 24, a shredding roller 25, a cutting tooth 26, a drive box 27, a crushing mechanism 28 and a blanking dish 29, and the support column 21 is evenly installed on the mounting frame 1 by welding, the upper end of the support column 21 is installed with a crushing box 22 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com