Natural polymer modified functional air filtering material and preparation method thereof

An air filter material and natural polymer technology, applied in the separation method, dispersed particle filtration, filtration separation, etc., can solve the problems of special equipment, cumbersome modification process, secondary pollution, etc., and achieve formaldehyde removal and low gas passage resistance , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

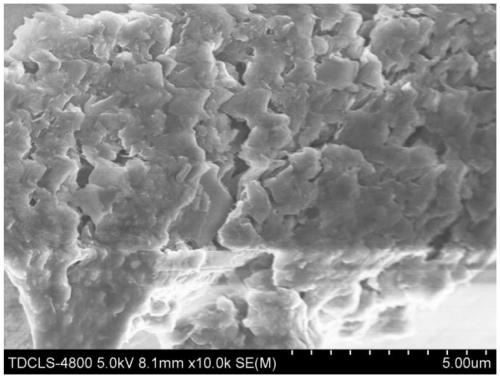

[0028] A preparation method of a natural polymer modified functional air filter material, firstly, the water-soluble chitosan can be dispersed in distilled water at 16% by mass, that is, the water-soluble chitosan can be dispersed in distilled water to form a mixture, and the water-soluble chitosan can be dispersed in distilled water to form a mixture. The quality of polysaccharide can account for 16% of the total mass of the mixture, and it can be stirred and dissolved in a water bath at 60°C to obtain a colloidal chitosan adhesive; Coating devices such as droppers, glass rods, scrapers, coating rods or automatic coating machines are evenly spread on the surface of the base fabric of polypropylene nonwoven fabrics, and the chitosan adhesive dripped from the base fabric is collected and coated On the surface of the base cloth; finally, dry the soaked base cloth at 50°C for 24 hours.

Embodiment 2

[0030] A preparation method of a natural polymer modified functional air filter material, firstly, water-soluble chitosan can be dispersed in distilled water at 28% by mass, that is, the water-soluble chitosan can be dispersed in distilled water to form a mixture, and the water-soluble chitosan can be dispersed in distilled water to form a mixture. The mass of polysaccharide can account for 28% of the total mass of the mixture, and it can be stirred and dissolved in a water bath at 60°C to obtain a colloidal chitosan adhesive; Coating devices such as droppers, glass rods, scrapers, coating rods or automatic coating machines are evenly spread on the surface of the base fabric of polypropylene nonwoven fabrics, and the chitosan adhesive dripped from the base fabric is collected and coated On the surface of the base cloth; finally, dry the soaked base cloth at 50°C for 24 hours.

Embodiment 3

[0032] A preparation method of a natural polymer modified functional air filter material, firstly, the water-soluble chitosan can be dispersed in distilled water according to the mass percentage of 37%, that is, the water-soluble chitosan can be dispersed in distilled water to form a mixture, and the water-soluble chitosan can be dispersed in distilled water to form a mixture. The quality of polysaccharide can account for 37% of the total mass of the mixture, and it can be stirred and dissolved in a water bath at 60°C to obtain a colloidal chitosan adhesive; Coating devices such as droppers, glass rods, scrapers, coating rods or automatic coating machines are evenly spread on the surface of the base fabric of polypropylene nonwoven fabrics, and the chitosan adhesive dripped from the base fabric is collected and coated On the surface of the base cloth; finally, dry the soaked base cloth at 50°C for 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com