Secondary assembly of composite insulation dry-type current transformer

A current transformer and composite insulation technology, which is applied in the direction of inductors, transformer/inductor coils/windings/connections, transformer/inductor shells, etc., can solve the problem of fixed, unmatched nuts, and inability to position the secondary terminal board Adjustment and other issues, to achieve the effect of flexible and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

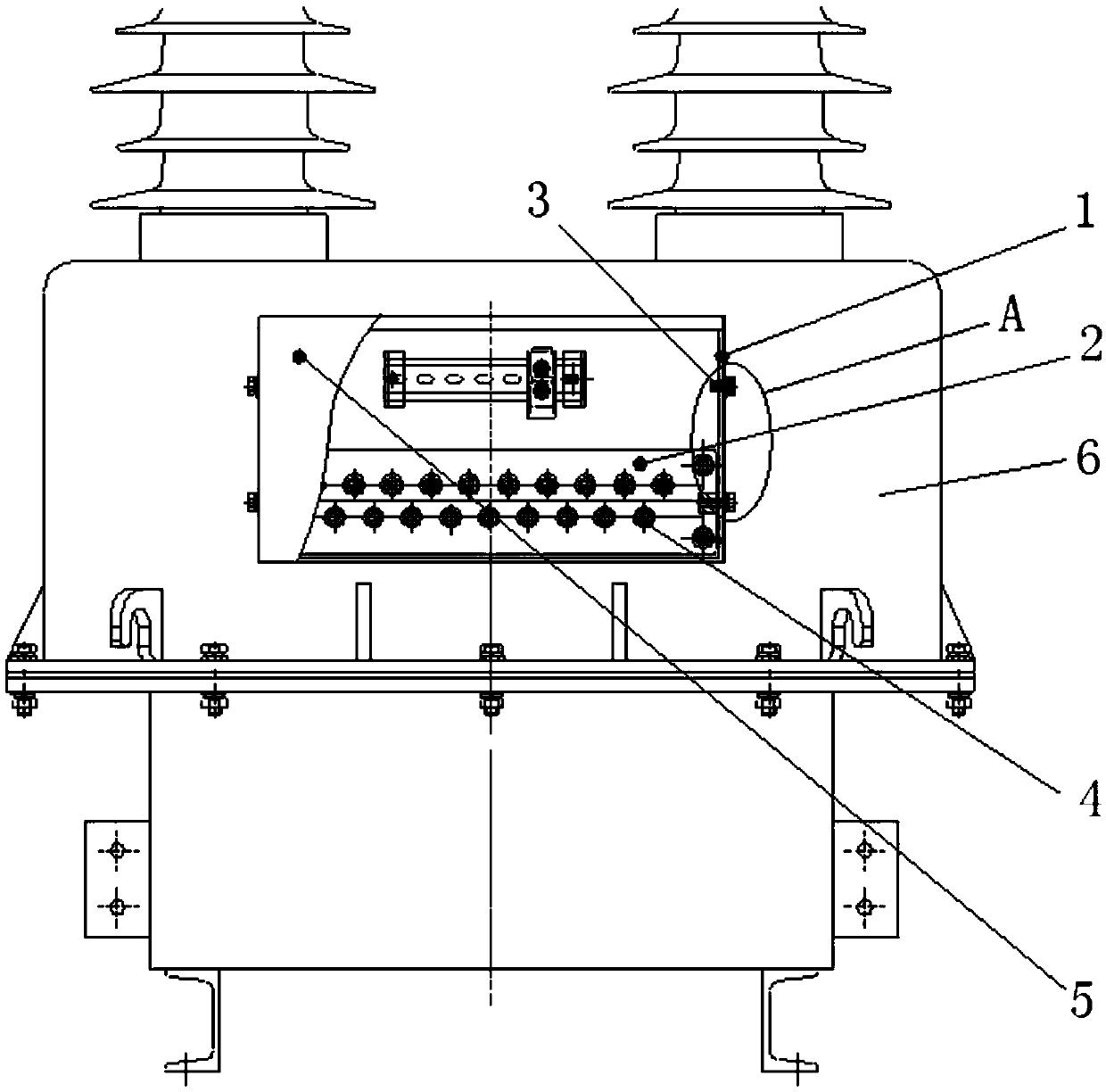

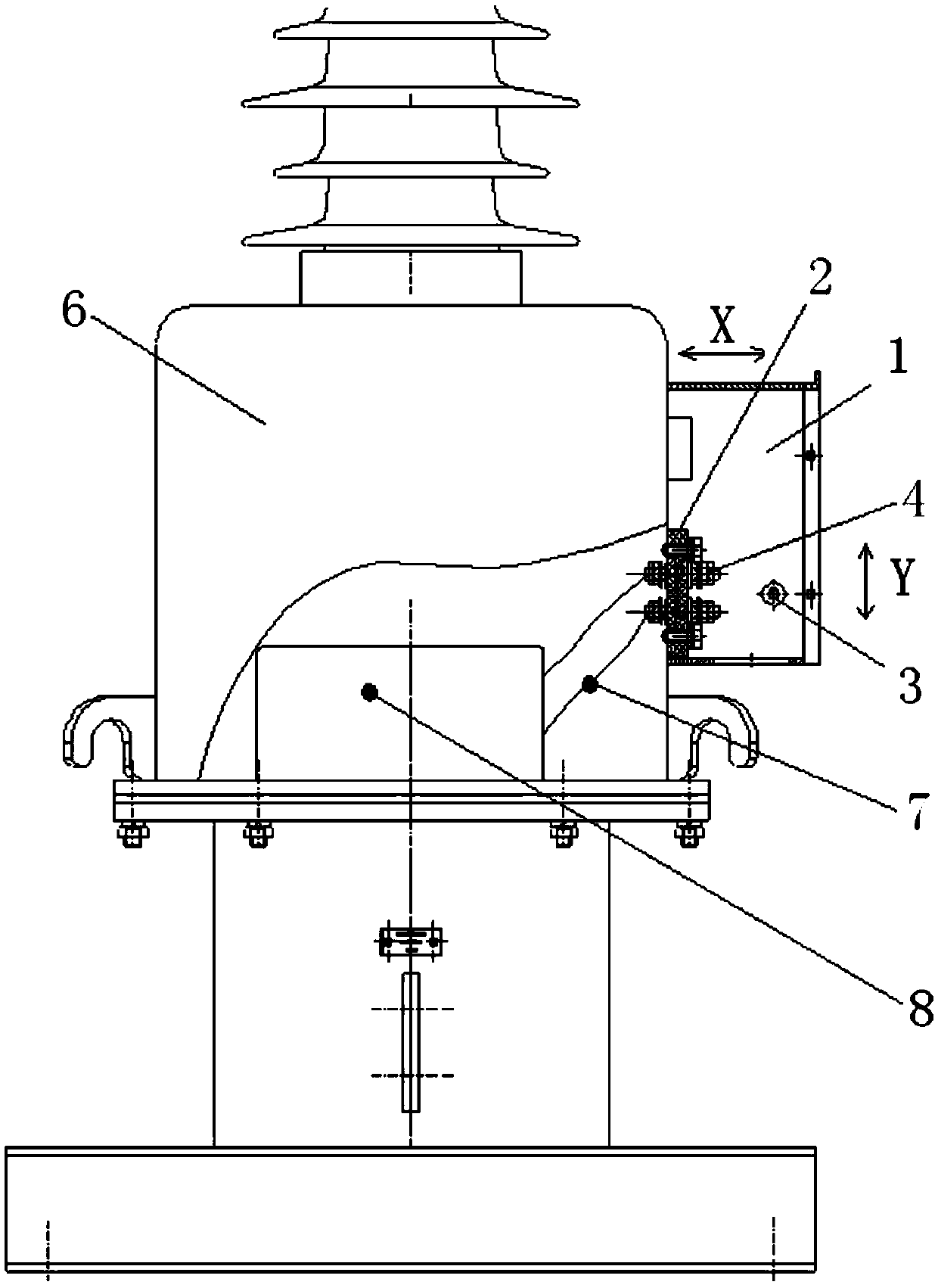

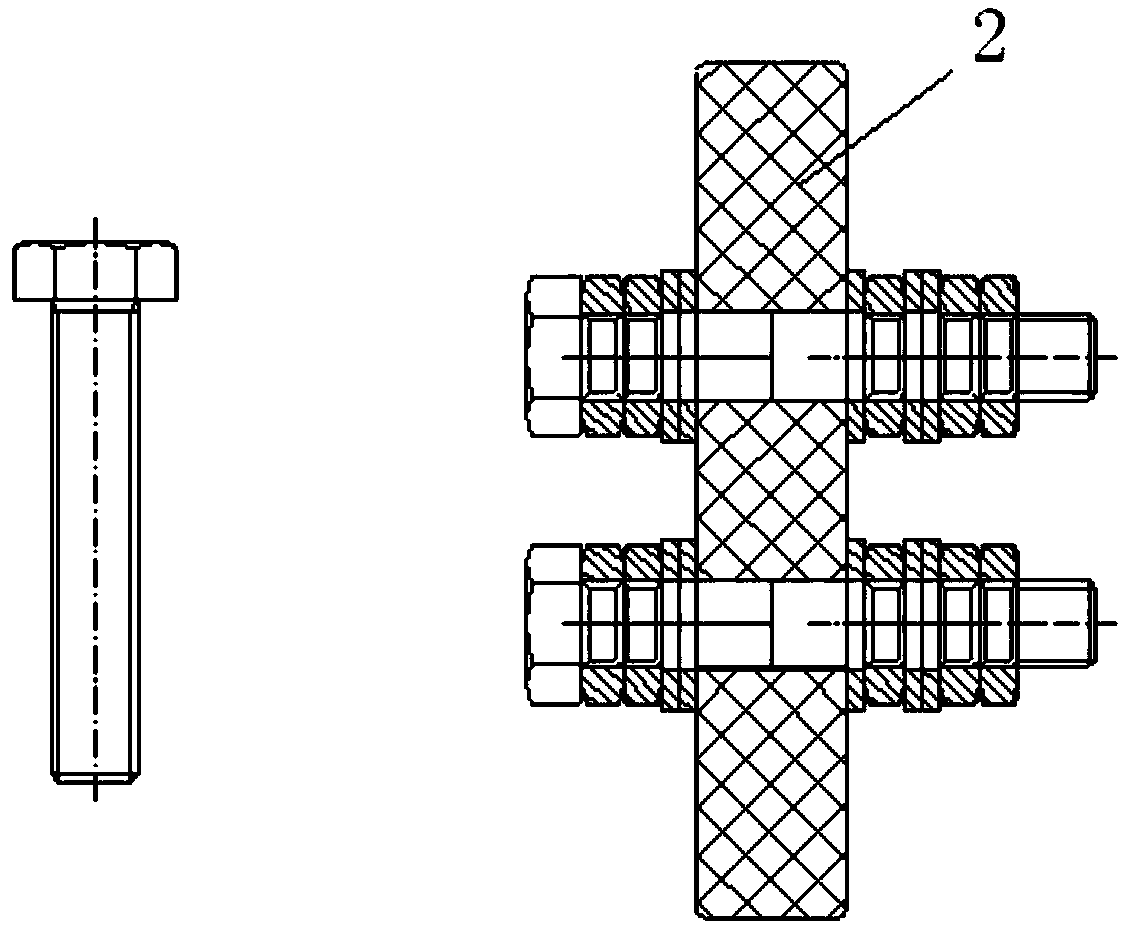

[0021] Such as Figure 1~2 As shown, the present invention includes a secondary coil 8, a secondary wiring board 2 and a secondary wiring terminal 4, the secondary wiring terminal 4 is arranged on the secondary wiring board 2, and the secondary coil 8 connects with the secondary wiring 7 through the secondary lead wire 7. The secondary terminal 4 on the wiring board 2 is connected, such as Figure 4 As shown, the secondary terminal 4 includes a stud and a nut, wherein the stud includes a middle optical axis section and threaded sections at both ends, and the optical axis section is provided with a terminal limit block 401, and the secondary The terminal block 2 is provided with a limit groove that cooperates with the terminal limit block 401. During installation, the studs pass through the secondary terminal block 2 and the terminal limit block 401 in the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com