Nylon fabric slight-plasticizing softening finishing method

A technology of softening finishing and softening agent, which is applied in fiber treatment, textiles and papermaking, and improved handle fibers, etc. It can solve the problems of non-washable, weak adhesion of nylon fibers, etc., and achieve improved washability and excellent soft feel , Penetration performance and adhesion performance enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

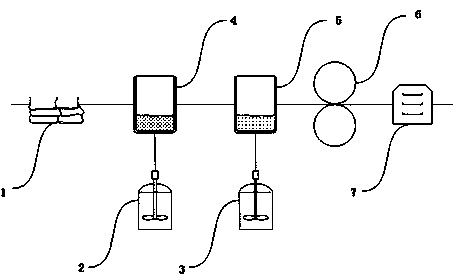

Image

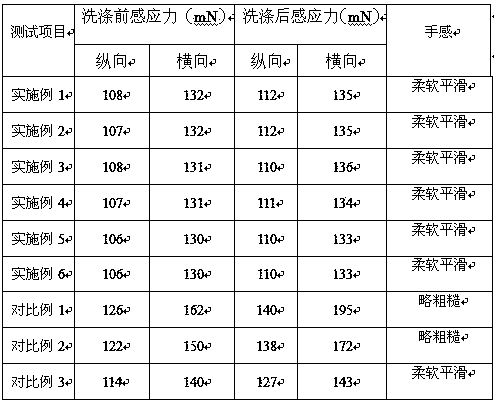

Examples

Embodiment 1

[0030]A method for micro-plasticizing and softening nylon fabrics, comprising the steps of:

[0031] Step 1, soaking the nylon fabric in 9wt% diammonium hydrogen citrate aqueous solution for 12 hours to obtain a pre-impregnated nylon fabric;

[0032] Step 2, put the pre-impregnated nylon fabric into the softening agent and soak for 10s, wherein the softening agent includes the following components in parts by weight: 5.0 parts of amino silicone oil, 5.0 parts of hydroxyl-terminated polysiloxane emulsion, 35 parts water; the amino silicone oil is amino silicone oil 8040, the ammonia value of the amino silicone oil 8040 is 0.38, and the viscosity (25°C) of the amino silicone oil 8040 is 3000cP; the hydroxyl-terminated polysiloxane emulsion is hydroxyl-terminated polysiloxane Siloxane WS62M, the molecular weight of the hydroxyl-terminated polysiloxane WS62M is 60,000 to 80,000;

[0033] Step 3, take out the nylon fabric soaked in step 2, and then use the padding machine twice, t...

Embodiment 2

[0035] A method for micro-plasticizing and softening nylon fabrics, comprising the steps of:

[0036] Step 1, soaking the nylon fabric in 13wt% diammonium hydrogen citrate aqueous solution for 6 hours to obtain a pre-impregnated nylon fabric;

[0037] Step 2, soak the pre-impregnated nylon fabric in softening agent for 11s, wherein the softening agent includes the following components in parts by weight: 10.0 parts of amino silicone oil, 8.0 parts of hydroxyl-terminated polysiloxane emulsion, 50 parts water; the amino silicone oil is amino silicone oil 8040, the ammonia value of the amino silicone oil 8040 is 0.42, and the viscosity (25°C) of the amino silicone oil 8040 is 4000cP; the hydroxyl-terminated polysiloxane emulsion is hydroxyl-terminated polysiloxane Siloxane WS62M, the molecular weight of the hydroxyl-terminated polysiloxane WS62M is 60,000 to 80,000;

[0038] Step 3, take out the nylon fabric soaked in step 2, and then use the padding machine twice, the total liq...

Embodiment 3

[0040] A method for micro-plasticizing and softening nylon fabrics, comprising the steps of:

[0041] Step 1, soaking the nylon fabric in 10wt% diammonium hydrogen citrate aqueous solution for 10 hours to obtain a pre-impregnated nylon fabric;

[0042] Step 2, put the pre-impregnated nylon fabric into the softening agent and soak for 10s, wherein the softening agent includes the following components in parts by weight: 7.0 parts of amino silicone oil, 6.0 parts of hydroxyl-terminated polysiloxane emulsion, 40 parts water; the amino silicone oil is amino silicone oil 8040, the ammonia value of the amino silicone oil 8040 is 0.40, and the viscosity (25°C) of the amino silicone oil 8040 is 3500cP; the hydroxyl-terminated polysiloxane emulsion is hydroxyl-terminated polysiloxane Siloxane WS62M, the molecular weight of the hydroxyl-terminated polysiloxane WS62M is 60,000 to 80,000;

[0043] Step 3, take out the nylon fabric soaked in step 2, then use the padding machine twice, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com