Antibacterial ink and preparation method thereof

A technology of ink and antibacterial agent, which is applied in the field of antibacterial ink and its preparation, can solve the problems that ink is prone to mildew and harm to human body during long-term storage, and achieves the effect of ensuring long-term storage without deterioration, no pollution to the environment, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

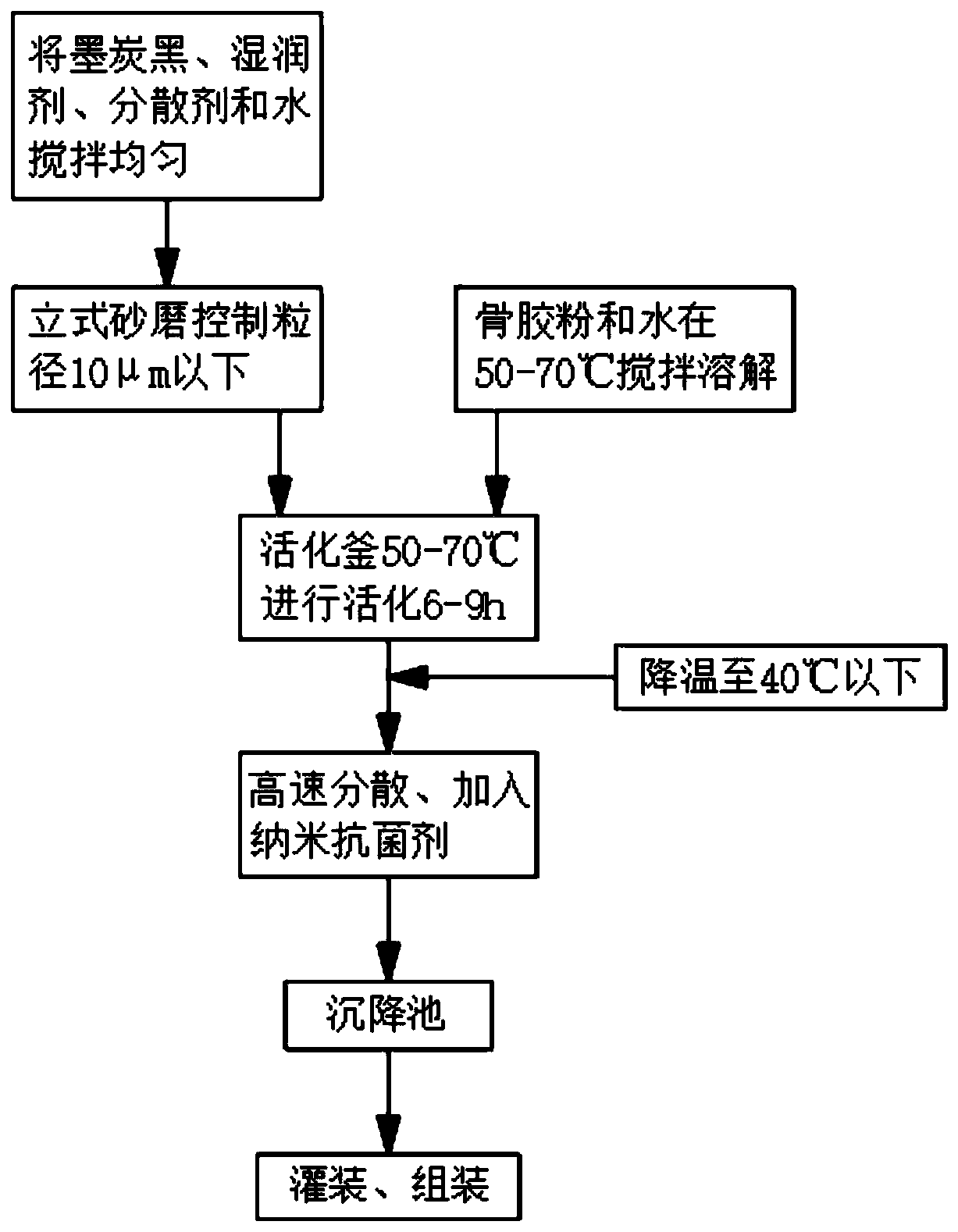

Method used

Image

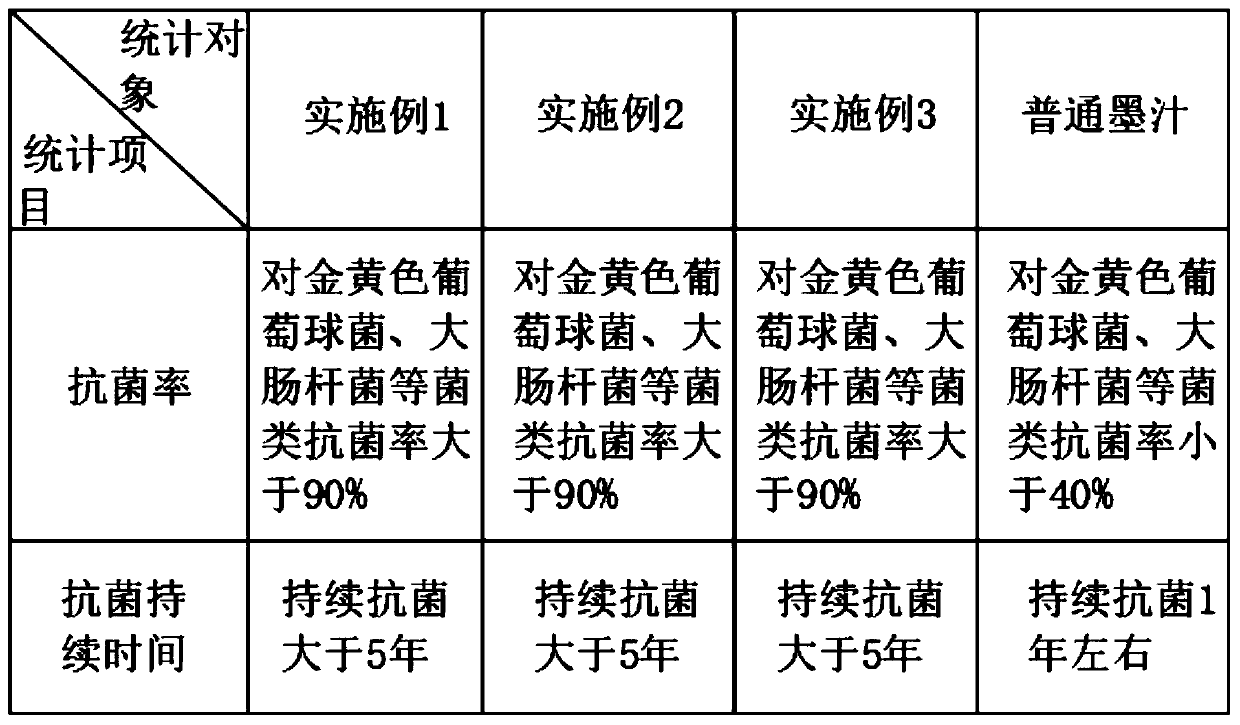

Examples

Embodiment 1

[0029] S1. Select 1 part of raw material ink carbon black, 1 part of wetting agent, 3 parts of dispersant, 10 parts of bone glue powder, 320 parts of water, 0.5 part of nano-inorganic antibacterial agent, and weigh the raw materials according to parts by weight;

[0030] S2. Select the ink carbon black, wetting agent, dispersant and 20 parts of water in step S1 and add them to the mixing mixer for uniform mixing. After the mixing is completed, add them to the vertical sand mill, and proceed through the vertical sand mill. Sand milling, through the high-speed friction of the zirconium beads and the dispersing disk, the particle size of the material is less than 10μm, and the ink slurry is made;

[0031] S3. Select the bone glue powder and the remaining 300 parts of water in step S1, add them to the mixing mixer, the mixer speed is controlled at 80r / min, the temperature is controlled at 50°C, and the bone glue powder is stirred and dissolved to obtain the bone glue liquid;

[0032] S4....

Embodiment 2

[0037] S1. Select 3 parts of raw material ink carbon black, 1.5 parts of wetting agent, 5 parts of dispersant, 7 parts of bone glue powder, 430 parts of water, 0.4 parts of nano-inorganic antibacterial agent, and weigh the raw materials according to parts by weight;

[0038] S2. Select the ink carbon black, wetting agent, dispersant and 30 parts of water in step S1 and add them to the mixing mixer for uniform mixing. After the mixing is complete, add them to the vertical sand mill and perform the process through the vertical sand mill. Sand milling, through the high-speed friction of the zirconium beads and the dispersing disk, the particle size of the material is less than 10μm, and the ink slurry is made;

[0039] S3. Select the bone glue powder and the remaining 400 parts of water in step S1, and add them to the mixing mixer, the mixer speed is controlled at 90r / min, the temperature is controlled at 60°C, and the bone glue powder is stirred and dissolved to obtain the bone glue l...

Embodiment 3

[0045] S1. Select 5 parts of raw ink carbon black, 2 parts of wetting agent, 7 parts of dispersant, 4 parts of bone glue powder, 540 parts of water, and 0.3 part of nano-inorganic antibacterial agent, and weigh the raw materials according to parts by weight;

[0046] S2. Select the ink carbon black, wetting agent, dispersant and 40 parts of water in step S1 and add them to the mixing mixer for uniform mixing. After the mixing is completed, add them to the vertical sand mill and perform the process by the vertical sand mill Sand milling, through the high-speed friction of the zirconium beads and the dispersing disk, the particle size of the material is less than 10μm, and the ink slurry is made;

[0047] S3. Select the bone glue powder and the remaining 500 parts of water in step S1, and add them to the mixing mixer, the rotation speed of the mixer is controlled at 100r / min, the temperature is controlled at 70°C, and the bone glue powder is stirred and dissolved to obtain the bone gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com