Polyurethane raw material composition, preparation method and application of polyurethane rigid foam

A technology of raw material composition and polyurethane rigid foam, which is applied in the field of polyurethane raw material composition, can solve the problems of inconsistency in performance and low thermal conductivity, achieve good dimensional stability, good heat insulation effect, improve fluidity and controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

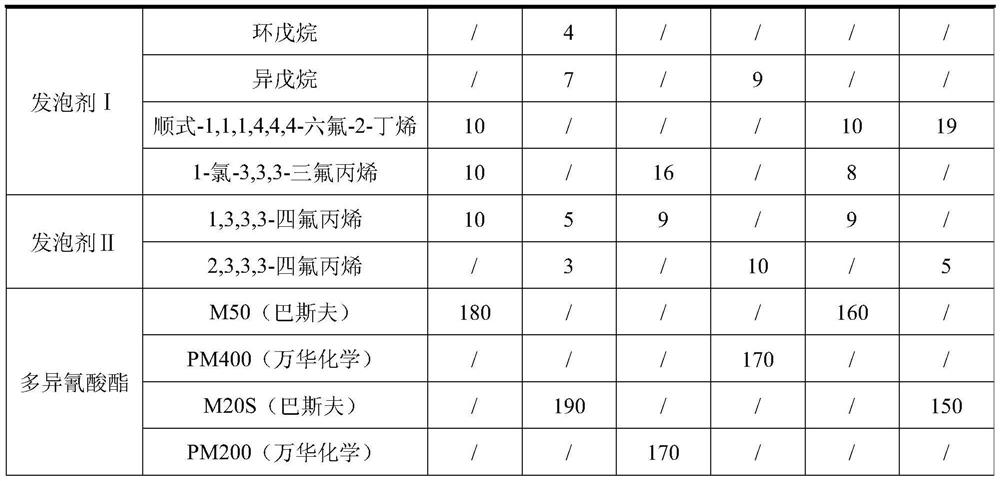

Embodiment 1

[0045] According to the 1# formulation components in Table 1, mix the complex polyol, adhesion promoter, foam stabilizer, catalyst and water evenly to obtain the combined polyether, then add foaming agent I, mix evenly, and control the system temperature to 28°C to obtain mixed component A; add foaming agent II to isocyanate, mix well, and control the system temperature to 12°C to obtain mixed component B; mix mixed component A and mixed component B under normal pressure, inject In the mold, the mold temperature is 50°C, and the demoulding time is 160s to obtain 1# polyurethane foam.

Embodiment 2

[0047] According to the 2# formulation components in Table 1, mix the complex polyol, adhesion promoter, foam stabilizer, catalyst and water evenly to obtain the combined polyether, then add foaming agent I, mix evenly, and control the system temperature to 25°C to obtain mixed component A; add foaming agent II to isocyanate, mix well, and control the system temperature to 5°C to obtain mixed component B; mix mixed component A and mixed component B under normal pressure, inject In the mold, the mold temperature was 40°C, and the demoulding time was 163s to obtain 2# polyurethane foam.

Embodiment 3

[0049] According to the 3# formulation components in Table 1, mix the complex polyol, adhesion promoter, foam stabilizer, catalyst and water evenly to obtain the combined polyether, first add foaming agent I, then add foaming agent II, mix Uniform and control the system temperature at 15°C to obtain mixed component C; adjust the temperature of isocyanate to 15°C; mix mixed component C and isocyanate under normal pressure, inject it into the mold, the mold temperature is 38°C, and the demoulding time is 165s to obtain 3 #Polyurethane foam.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com