Ink, screen assembly using same, and electronic equipment

A technology of ink and components, applied in the direction of ink, sub-office equipment, applications, etc., can solve problems that affect the reliability of screen bonding and low bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0120] 1. Preparation of ink

[0121] In parts by mass, put a mixed solvent of 20 parts of ethyl acetate and 15 parts of butyl acetate into the kettle, add 39.5 parts of epoxy resin, add 15 parts of carbon black (MA100), disperse and stir evenly, and use a sand mill to obtain the mixture Grind three times, control the temperature of the material during the grinding process to not exceed 40°C, then discharge the material, add 10 parts of calcium carbonate, 0.25 parts of silicone defoamer, and 0.25 parts of silicone leveling agent, disperse and stir evenly, grind three times with a sand mill, Afterwards, the material is discharged and filtered to obtain a black ink with high adhesion to PUR.

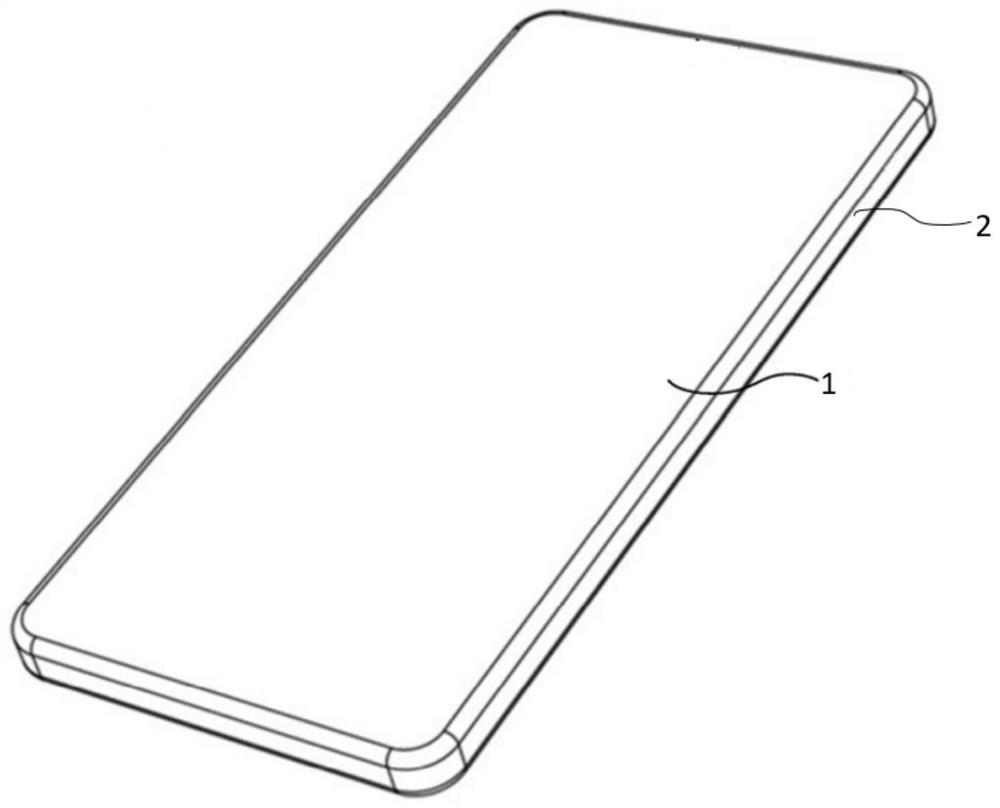

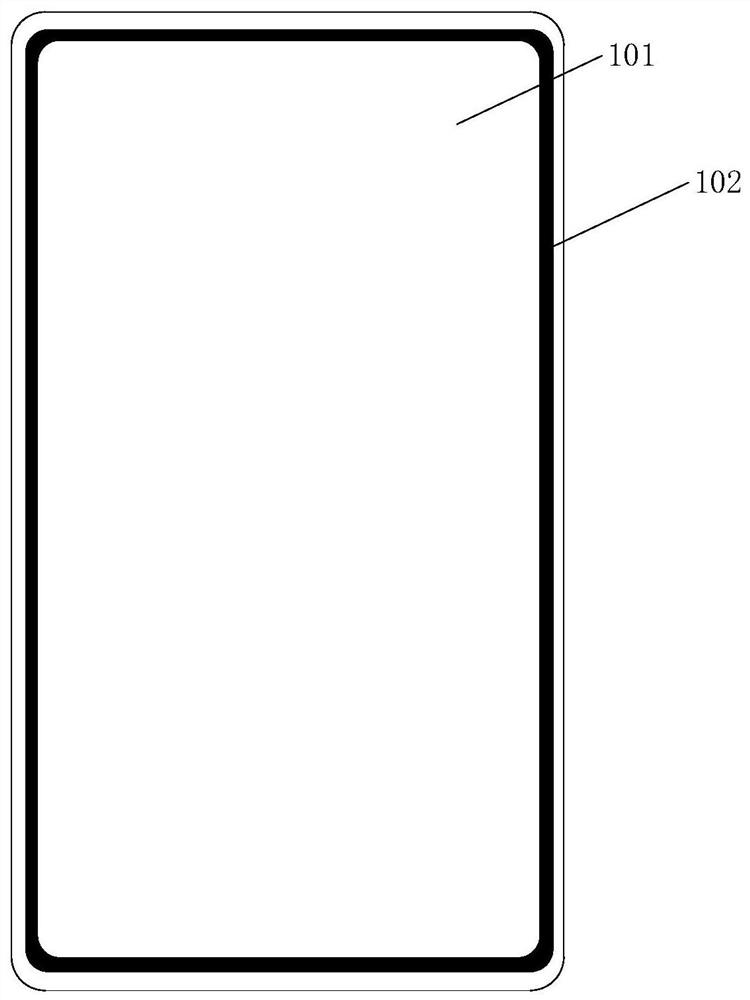

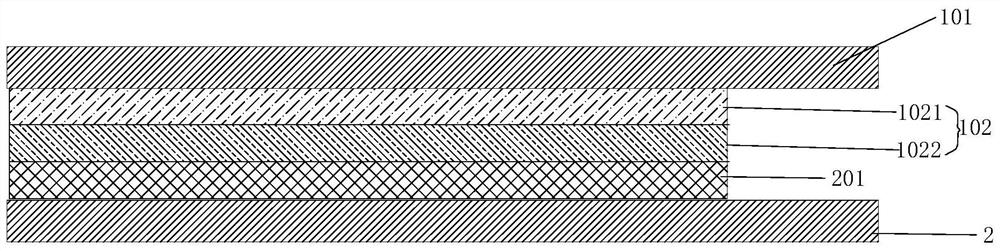

[0122] 2. Preparation of screen components

[0123] Put the above black ink on a screen printing machine, use a 300-mesh screen to print on the screen cover, and after curing in a temperature-controlled tunnel oven at 160°C for 10 minutes, take it out and form an ink layer on the edge of ...

Embodiment 2-10

[0126] The preparation process of ink and screen assembly in embodiment 2-10 is the same as embodiment 1, and the difference between embodiment 2-10 and embodiment 1 is that the composition of ink is different, each component in the ink of embodiment 1-10 and Its dosage is shown in Table 1 below.

Embodiment 2

[0145] In Example 2, the diluent includes 20 parts of ethyl acetate and 20 parts of butyl acetate, and the filler is 9 parts of calcium carbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com