Corrugated structure-based sliding type flexible composite material skin

A technology of composite materials and composite material thin plates, applied in the field of sliding flexible composite material skins, which can solve the problems of weight, structural complexity or difficulty in maintaining a smooth aerodynamic surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

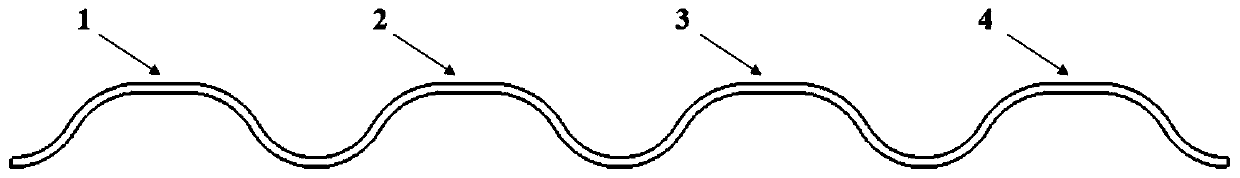

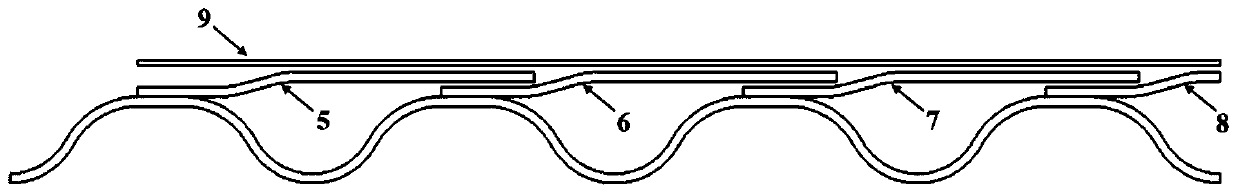

[0016] The sliding flexible composite material skin based on the corrugated structure with large deformation function of the present invention is composed of a composite material corrugated plate, a composite material thin plate and an elastomer layer. Composite corrugated sheets (such as figure 1 shown) has a continuous cross-sectional shape There are glued surface 1, glued surface 2, glued surface 3 and glued surface 4 at the crest, where the composite material corrugated board is a unidirectional belt laminated corrugated sheet made of carbon fiber, glass fiber, Kevlar fiber and boron fiber panels, and corrugated panels of woven materials made of carbon fiber, glass fiber, Kevlar fiber, and boron fiber. The composite material corrugated plate has a large deformation capacity along the corrugated direction. When a certain tension is app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com