Vacuum sintering process for hard alloy sawteeth

A cemented carbide and vacuum sintering technology, which is applied in the field of cemented carbide, can solve the problems affecting the performance of cemented carbide sawtooth products, and the sintered filler is not stable enough, and achieves the effects of good sintering effect, small porosity and uniform heat conduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

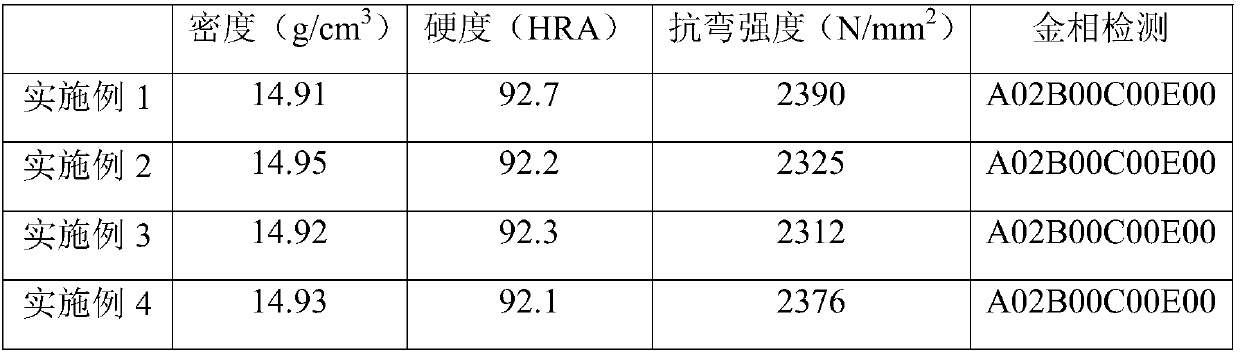

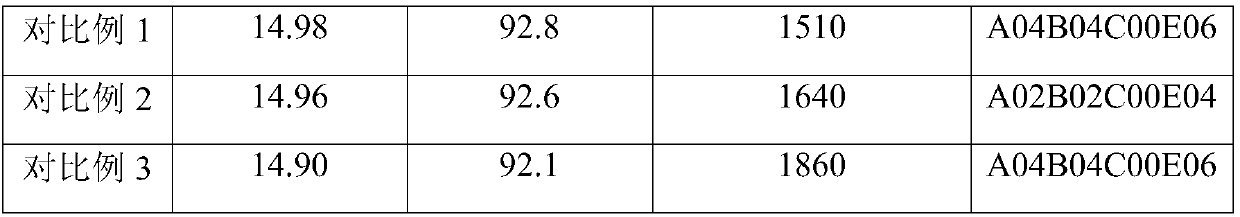

Examples

Embodiment 1

[0029] This embodiment provides a cemented carbide sawtooth vacuum sintering process, which specifically includes the following steps;

[0030] S1. Mix the tungsten carbide sawtooth blank and the sintered filler with a particle size of 80 mesh evenly. The sintered filler used is obtained by mixing the following components: titanium carbide powder: 89%, zirconia powder: 5%, alumina powder 5%, carbon Black: 1%. After mixing evenly, each cemented carbide sawtooth blank is wrapped by sintered material without contact with each other, and then put into a graphite boat, and the cemented carbide sawtooth blank is not in contact with the graphite boat;

[0031] S2. Put the graphite boat containing the mixed material into a vacuum sintering furnace for sintering. The sintering process parameters are as follows: the temperature is 1400° C., and the time is 120 minutes;

[0032] S3. Sieve the sintered material in the graphite boat through a 20-mesh vibrating sieve to obtain cemented carb...

Embodiment 2

[0034] This embodiment provides a cemented carbide sawtooth vacuum sintering process, which specifically includes the following steps;

[0035] S1. Mix the tungsten carbide sawtooth blank and the sintered filler with a particle size of 60 mesh evenly. The sintered filler used is obtained by mixing the following components: titanium carbide powder: 89%, zirconia powder: 1%, alumina powder 9%, carbon Black: 1%. After mixing evenly, each cemented carbide sawtooth blank is wrapped by sintered material without contact with each other, and then put into a graphite boat, and the cemented carbide sawtooth blank is not in contact with the graphite boat;

[0036] S2. Put the graphite boat containing the mixed material into a vacuum sintering furnace for sintering. The sintering process parameters are as follows: the temperature is 1450° C., and the time is 60 minutes;

[0037] S3. Sieve the sintered material in the graphite boat through a 20-mesh vibrating sieve to obtain cemented carbi...

Embodiment 3

[0039] This embodiment provides a cemented carbide sawtooth vacuum sintering process, which specifically includes the following steps;

[0040] S1. Mix the cemented carbide sawtooth blank and sintered filler with a particle size of 40 mesh evenly. The sintered filler used is obtained by mixing the following components: titanium carbide powder: 89%, zirconia powder: 9%, alumina powder 1%, carbon Black: 1%. After mixing evenly, each cemented carbide sawtooth blank is wrapped by sintered material without contact with each other, and then put into a graphite boat, and the cemented carbide sawtooth blank is not in contact with the graphite boat;

[0041] S2. Put the graphite boat containing the mixed material into a vacuum sintering furnace for sintering. The sintering process parameters are as follows: the temperature is 1400° C., and the time is 80 minutes;

[0042] S3. Sieve the sintered material in the graphite boat through a 20-mesh vibrating sieve to obtain cemented carbide s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com