Biochar capable of adsorbing heavy metals as well as preparation method and application thereof

A technology for adsorbing heavy metals and biochar, applied in carbon preparation/purification, non-metallic elements, chemical instruments and methods, etc., can solve problems such as high cost, complicated treatment process, and many steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 7

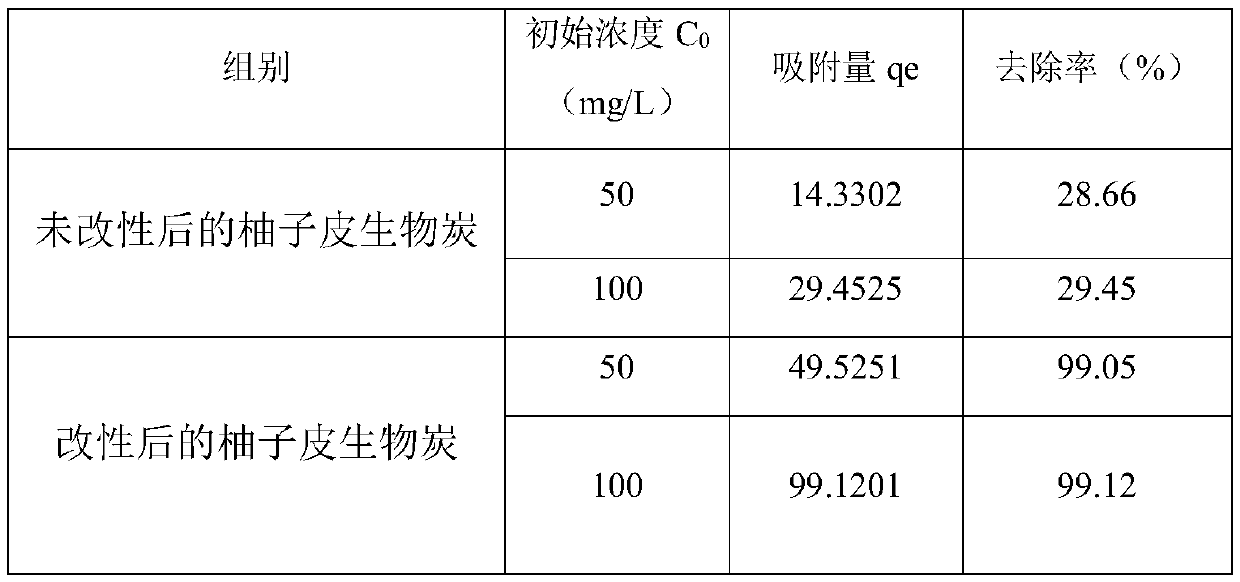

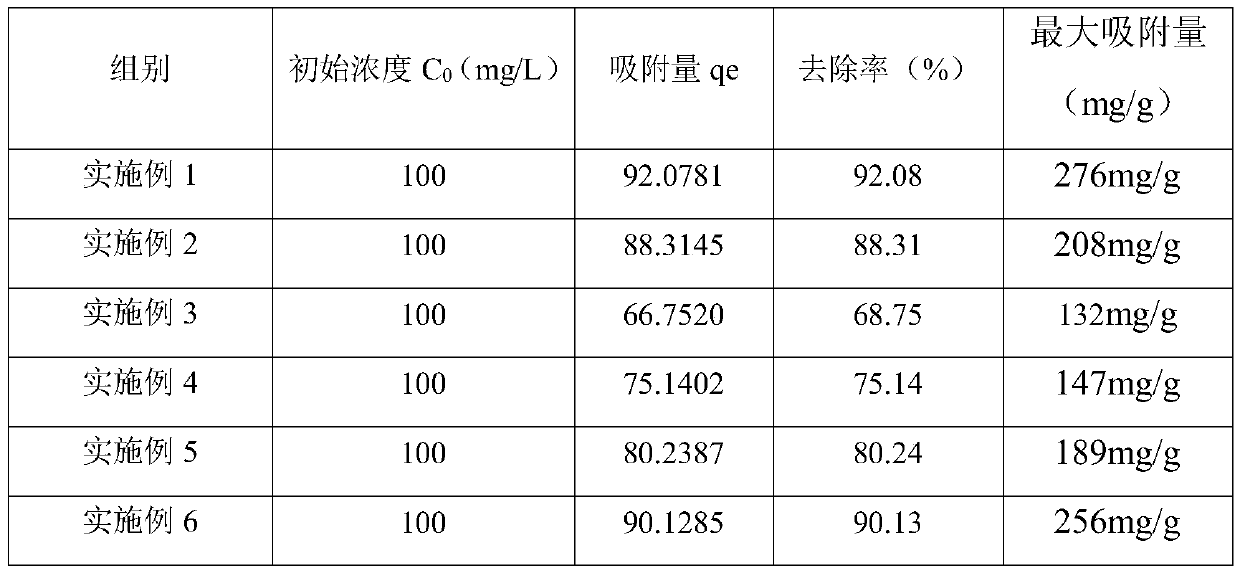

[0093] Example 7 Copper ion adsorption experiment

[0094] Weigh 0.05g each of the samples obtained from the above examples 1 to 6 and place them in a 500ml wide-mouthed Erlenmeyer flask. In each sample, add CU at a concentration of 100mg / L. 2+ Solution. Place the Erlenmeyer flask in a double-layer constant temperature shaker at (25±5)℃, shake at 150r / min for 12h, take out the 0.45μm microporous membrane, and measure Cu in the filtrate by flame atomic absorption spectrometer 2+ , And calculate the combined material of different embodiments to Cu in solution 2+ The adsorption capacity and removal rate.

[0095] It can be seen from Table 7 that the adsorption capacity of the composite adsorbents with different composition ratios to copper ions is obviously different; 2+ The adsorption effect is also the strongest, followed by Example 6, which is better than other groups, indicating that the composite adsorption material composed of the raw materials of Example 1 of the present inventi...

Embodiment 8

[0098] Example 8 Nickel ion adsorption experiment

[0099] Weigh 0.05g each of the samples prepared in the above Examples 1 to 6 and place them in a 500ml wide-mouth Erlenmeyer flask. Add Ni at a concentration of 100mg / L to each sample. 2+ Solution. Place the Erlenmeyer flask in a double-layer constant temperature shaker at (25±5)℃, oscillate at 150r / min for 12h, remove the 0.45μm microporous membrane, and measure the Ni in the filtrate by flame atomic absorption spectrometer 2+ , And calculate the combined material of different embodiments to the Ni in solution 2+ The adsorption capacity and removal rate.

[0100] It can be seen from Table 8 that the adsorption capacity of the composite adsorbents with different composition ratios to nickel ions is significantly different; 2+ The adsorption effect of is also the strongest, better than other groups, indicating that the composite adsorption material composed of the raw materials of Example 1 of the present invention can achieve bette...

Embodiment 9

[0103] Example 9 Chromium ion adsorption experiment

[0104] Weigh 0.05g each of the samples prepared in the above Example 1 to Example 6 and place them in a 500ml wide-mouth Erlenmeyer flask. Each sample is added with a concentration of 100mg / L Cd 2+ Solution. Place the Erlenmeyer flask in a double-layer constant temperature shaker at (25±5)℃, shake at 150r / min for 12h, take out the 0.45μm microporous membrane, and use flame atomic absorption spectrometer to determine the Cd in the filtrate 2+ , And calculate the combination of materials in different embodiments to Cd in the solution 2+ The adsorption capacity and removal rate.

[0105] It can be seen from Table 9 that the adsorption capacity of the composite adsorbents with different composition ratios to chromium ions is obviously different; 2+ The adsorption effect is better than other groups, indicating that the composite adsorption material composed of the raw materials of Example 1 of the present invention has a larger specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com