Modified activated carbon, preparation method thereof and method for removing bromate in water

A technology of activated carbon and bromate, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve the problems of low adsorption efficiency of raw carbon, weakened removal effect of bromate, and shedding of modifiers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

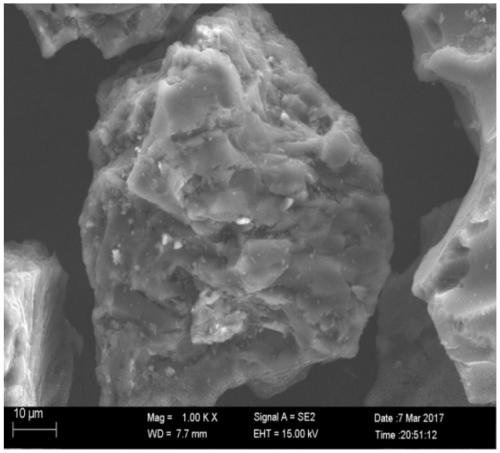

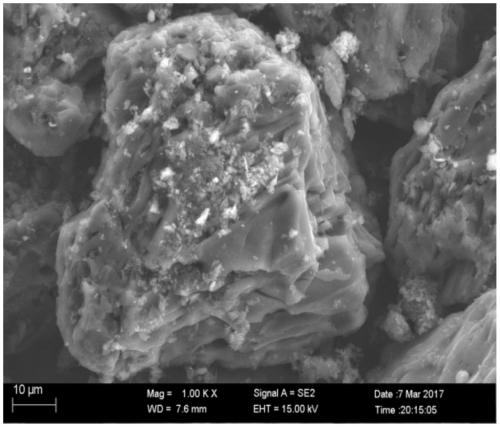

[0066] Provide a kind of modified active carbon, make like this:

[0067] Step (1): First, take 1.5 g of pretreated coal-based activated carbon (GAC-O) and immerse it in (3-chloro-2-hydroxypropyl) dodecyldimethyl ammonium chloride (QUAB342) solution, The dosage ratio of QUAB342 / GAC-O was 3.81g / g, and it was stirred at room temperature for 24 hours to make the quaternary ammonium salt and activated carbon evenly mixed. Among them, the coal-based activated carbon pretreatment steps include: firstly crush the activated carbon with a pulverizer, then sieve it with a 200-mesh and 400-mesh sieve, select activated carbon between 200-400 mesh, and wash it with deionized water until it reaches 400 mesh. Put the water flowing down the mesh sieve into a 100mL evaporating dish, wash it three times with pure water, and finally put it in a drying oven at 105°C for 10 hours before use.

[0068] Step (2): At 30° C., add 1 mol / L NaOH solution, adjust the pH to 8.5, and react for 48 hours.

...

Embodiment 2

[0072] The basic steps are the same as in Example 1, except that the mass of activated carbon is 1.5g, the dosage of QUAB342 is 4.17g, the modification temperature is 50°C, and the modification pH is 12.

Embodiment 3

[0074] The basic steps are the same as in Example 2, except that the activated carbon is coconut shell activated carbon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com