Renewable friction generator, array, temperature sensor, electronic skin and method

A triboelectric generator and temperature sensor technology, applied in triboelectric generators, thermometers, thermometers using electrical/magnetic components that are directly sensitive to heat, etc., can solve problems such as unfavorable integration, and achieve the effect of stabilizing electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0053] In a first exemplary embodiment of the present disclosure, a regenerative friction generator is provided.

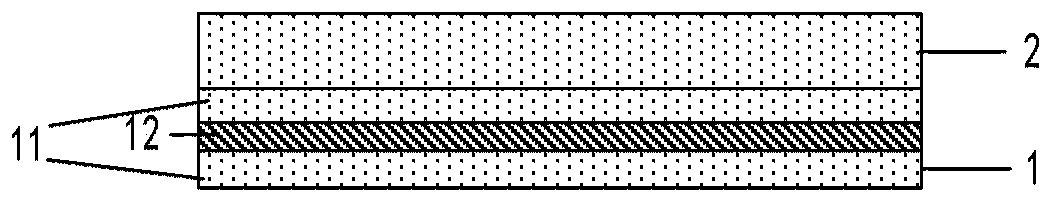

[0054] figure 1 It is a schematic structural diagram of a regenerative friction generator according to an embodiment of the present disclosure.

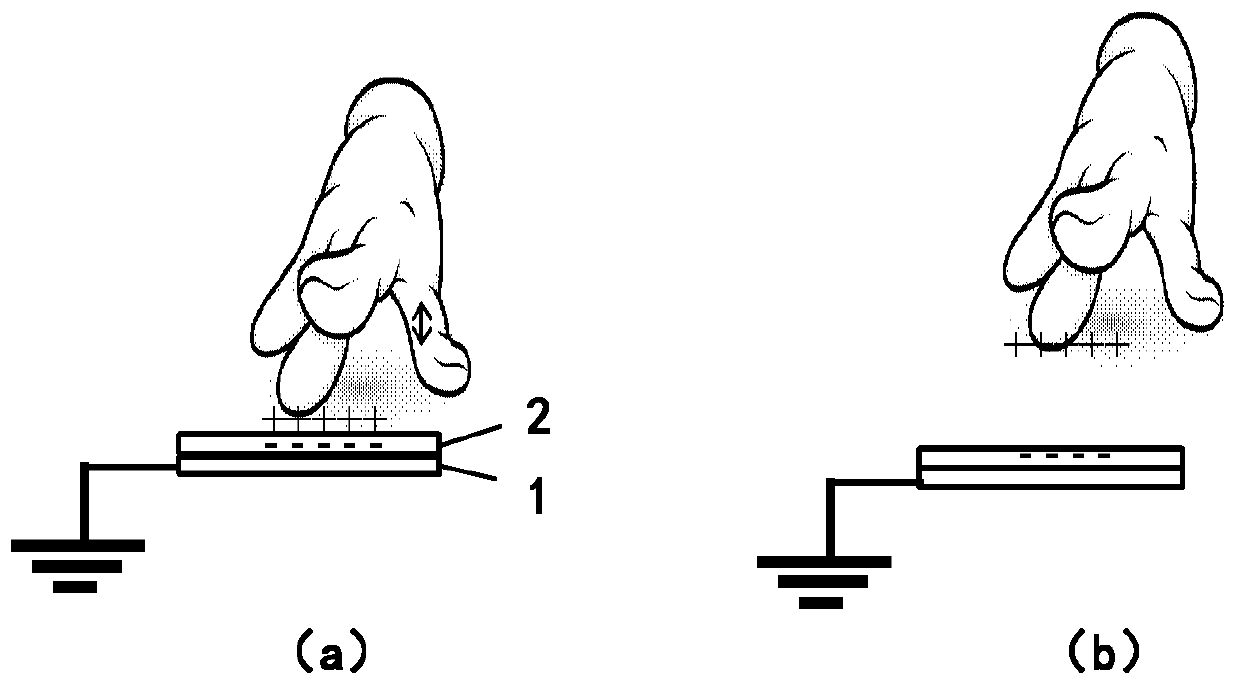

[0055] refer to figure 1 As shown, the regenerative triboelectric generator of this embodiment includes: a regenerative electrode layer 1, and the regenerative electrode layer 1 includes: metal nanowire-hydrogel; wherein, the metal nanowire-hydrogel is doped A hydrogel 11 with metal nanowires 12, the metal nanowires 12 can be separated from the hydrogel 11 in a water phase at a specific temperature to achieve regeneration, based on the reversibility of dynamic chemical bonds, the hydrogel 11 can be regenerated; and The friction layer 2 is located on the regenerative electrode layer 1, and the material of the friction layer 2 is hydrogel.

[0056] In this embodiment, preferably, the metal nanowires in the metal nanowir...

no. 2 example

[0075] In a second exemplary embodiment of the present disclosure, a method of preparing a metal nanowire-hydrogel having aligned metal nanowires is provided.

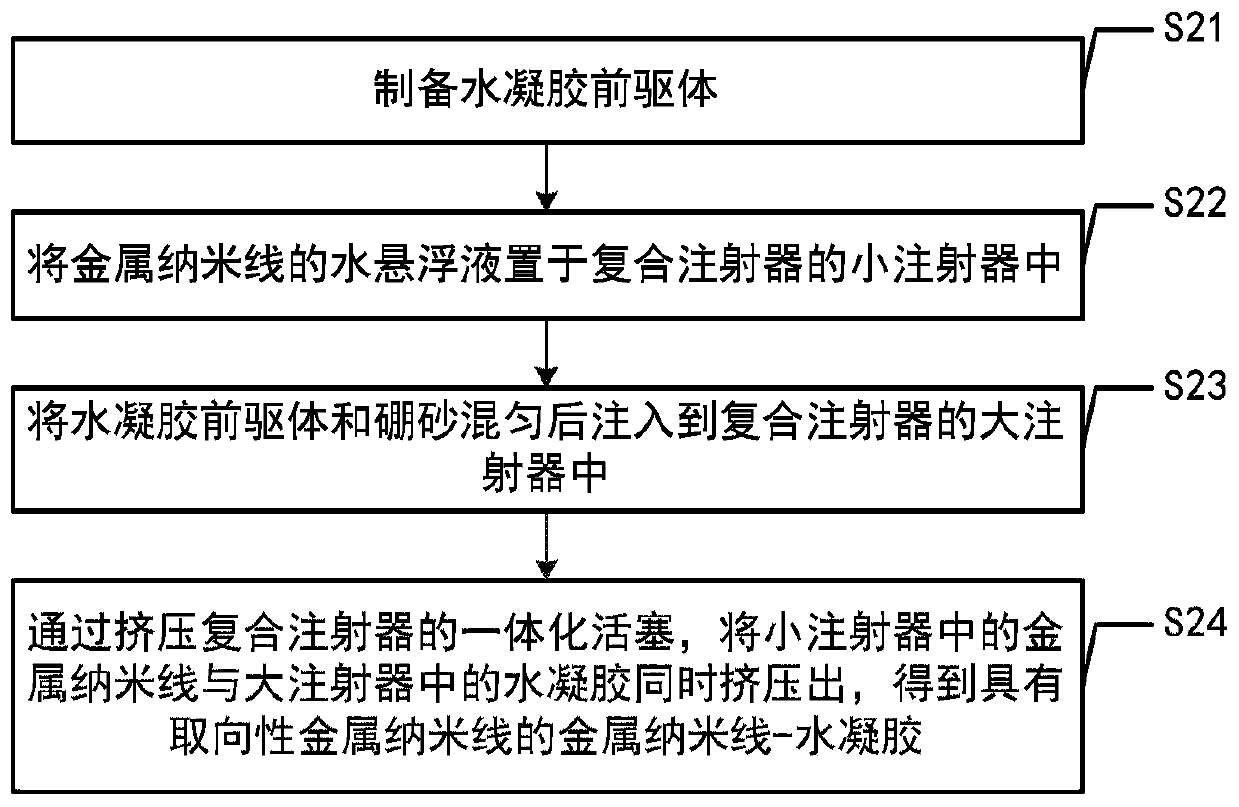

[0076] image 3 It is a flowchart of a method for preparing a metal nanowire-hydrogel with oriented metal nanowires according to an embodiment of the present disclosure.

[0077] refer to image 3 As shown, the method for preparing a metal nanowire-hydrogel with oriented metal nanowires in this embodiment includes:

[0078] Step S21: preparing a hydrogel precursor;

[0079] In one example, the preparation process of the hydrogel precursor is as follows: dissolve 10 grams of polyvinyl alcohol in 50 milliliters of hot water at 90°C, stir for 1 hour to form a transparent solution, add 0.5g-1.5g of sodium alginate and stir for 1 Hours later, after the sodium alginate was completely dissolved, 50 milliliters of 0.04 mol / L borax was added, and stirring was continued for 0.5 hours before the cross-linking reaction was adde...

no. 3 example

[0099] In a third exemplary embodiment of the present disclosure, an array of regenerative friction generators is provided.

[0100] Figure 10A It is a schematic structural diagram of a regenerative friction generator array according to an embodiment of the present disclosure.

[0101] refer to Figure 10A As shown, the regenerative friction generator array shown in this embodiment includes: an array of regenerative friction generators arranged on the same substrate 3, the regenerative friction generator is any of the regenerative friction generators mentioned in this disclosure dynamo.

[0102] Preferably, in the renewable triboelectric generator, the metal nanowires in the metal nanowire-hydrogel have orientation in the hydrogel.

[0103] Figure 10B It is an array arrangement form of the regenerative friction generator array shown in an embodiment of the present disclosure.

[0104] refer to Figure 10B As shown, an array arrangement form of the regenerative friction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com