Direct liquid cooling laser gain device based on split type flow channel

A laser gain, split technology, applied in laser cooling devices, lasers, laser parts and other directions, can solve the problems affecting the beam quality of direct liquid cooling laser devices, uneven liquid heat distribution, affecting laser transmission, etc., and achieve effective cooling. , The effect of improving the efficiency of use and reducing the demand for the total amount of coolant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

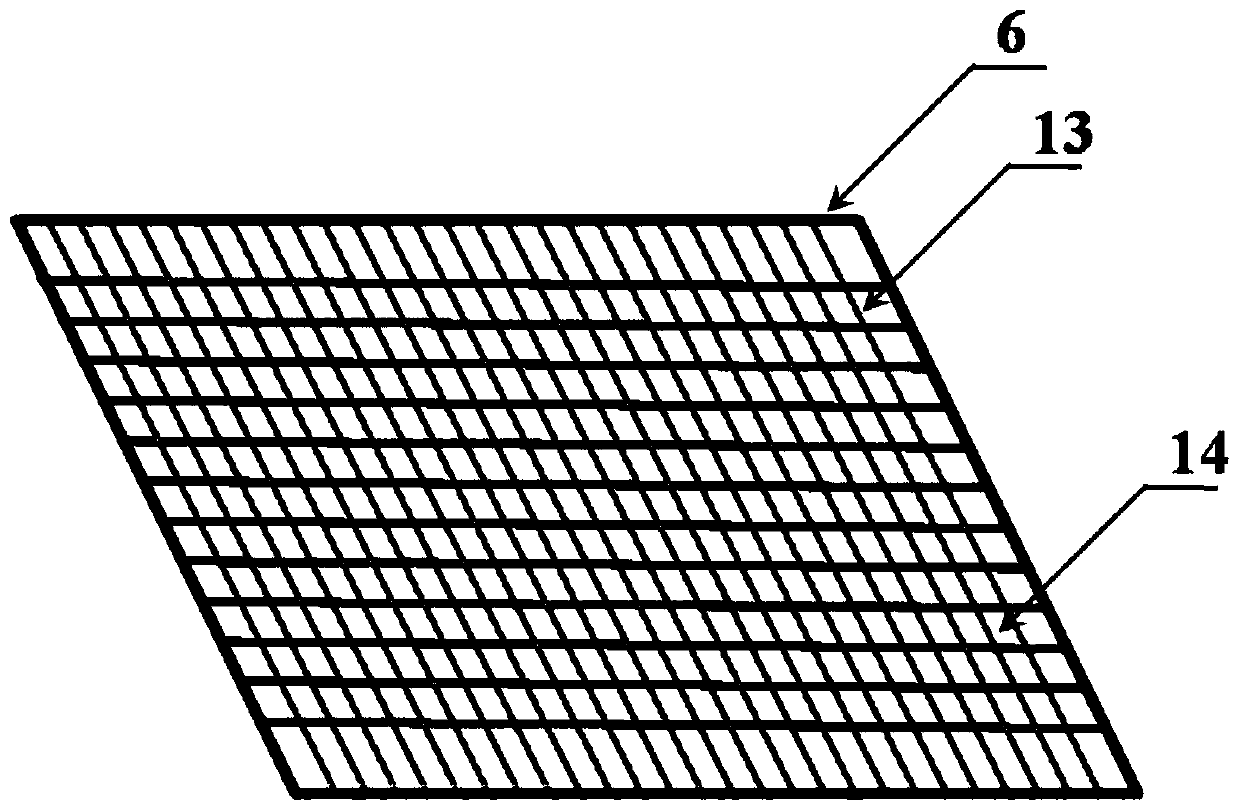

[0034] This embodiment discloses a direct liquid-cooled laser gain device based on a split channel, which includes a direct liquid-cooled array distributed laser gain module and an incoming flow guide cone 5 for splitting and homogenizing cooling liquid; the guide The flow cone 5 is arranged at the inlet of the cooling liquid of the laser gain module. In one embodiment, such as Figure 4 As shown, the incoming flow deflector cone 5 is composed of a conical shell and several cone inner deflectors 4 arranged inside.

[0035] The direct liquid-cooled array distributed laser gain module usually includes a laser window 9 and an arrayed laser gain medium. The arrayed laser gain medium is composed of several thin slices of laser gain medium, and the adjacent slices are separated by microchannel separators 7 Come. Generally speaking, the micro-channel dividing strips 7 are arranged on the four corners of the sheets, so that micro-channels for the cooling liquid to flow are formed be...

Embodiment 2

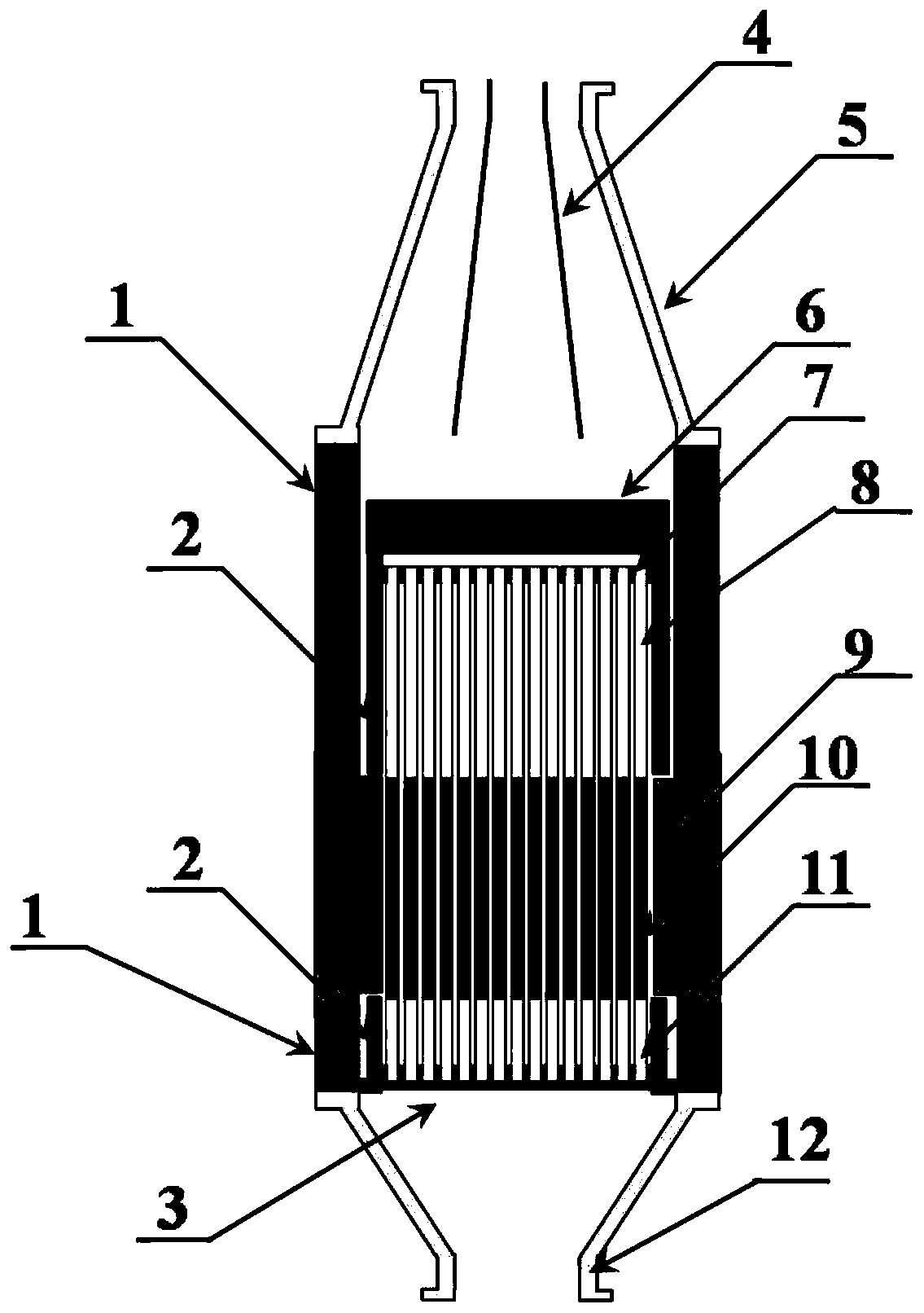

[0039] Such as figure 1As shown, this embodiment discloses a direct liquid-cooled laser gain device based on a split flow channel, which includes a direct liquid-cooled array distributed laser gain module and an incoming flow guide cone for splitting and homogenizing the cooling liquid 5. The guide cone 5 is arranged at the inlet of the cooling liquid of the laser gain module. The direct liquid-cooled array distributed laser gain module includes a frame structure, a laser window 9 and an arrayed laser gain medium, the laser window 9 is arranged on the frame structure, and the arrayed laser gain medium is arranged on the frame within the body structure.

[0040] The frame structure above includes an outer frame 1 and an inner frame 2 of the device, and the outer frame 1 and the inner frame 2 are designed separately, that is, there is a gap between them. The inner frame 2 is fixedly installed in the outer frame 1, and a laser window 9 is arranged on the outer frame 1 correspon...

Embodiment 3

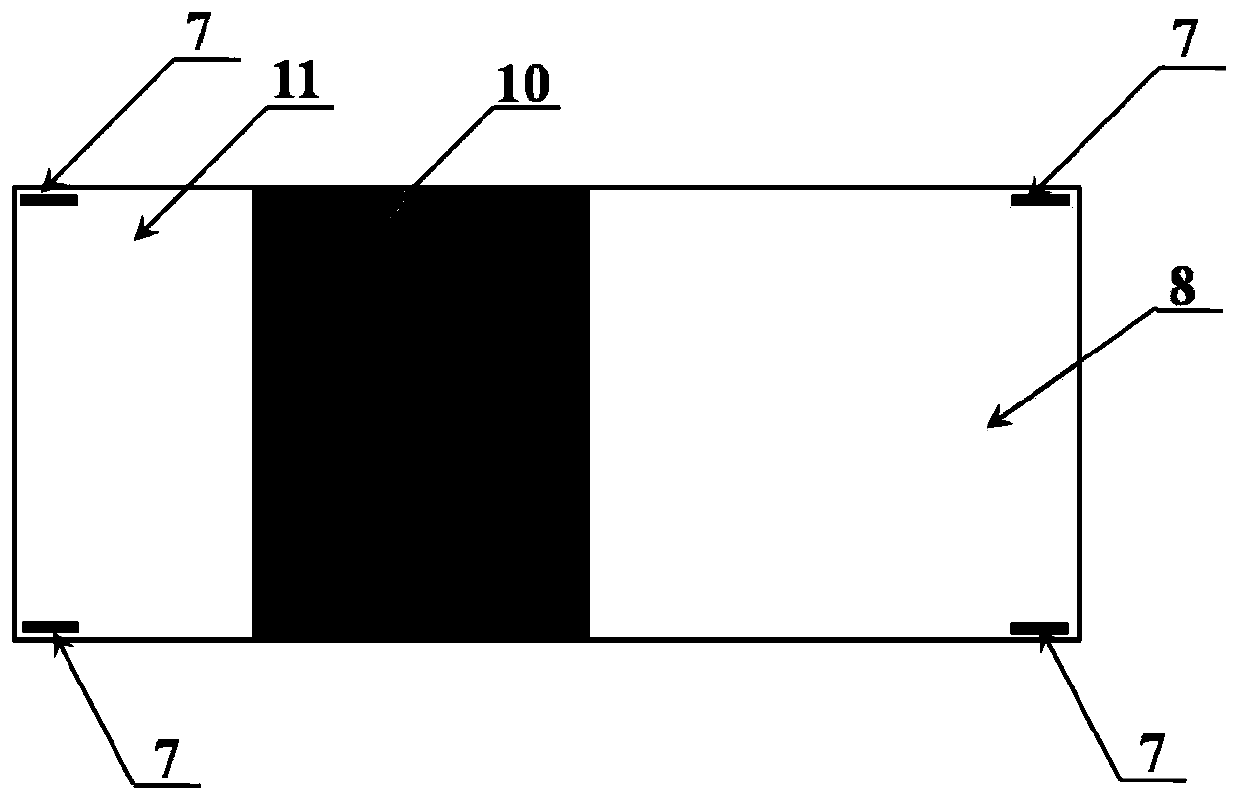

[0042] Such as figure 1 , 2 As shown, this embodiment discloses a structure of an arrayed laser gain medium. It is composed of several thin slices of laser gain medium and micro flow channel separators 7 between adjacent thin slices. Such as figure 2 As shown, the thin slice laser gain medium includes a dissipative segment crystal 8 (i.e. the first segment medium), a gain crystal 10 (i.e. the second segment medium), a recovery segment crystal 11 (i.e. the third segment medium), and between the three segment crystals is One-piece processing, can be connected as a whole by bonding, bonding, etc. Among them, the dissipative segment crystal 8 and the recovery segment crystal 11 are characterized by the fact that the matrix is the same as the gain crystal 10 but the dopant ions are different or have no dopant ions. The thin-sheet laser gain medium can be one or more of crystal, ceramic and glass materials.

[0043] On the four corners of each sheet (or other positions that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com