Qualitative diagnosis method for power frequency fault of rotary machinery

A technology of rotating machinery and diagnostic methods, applied in the testing of mechanical components, testing of machine/structural components, instruments, etc., can solve the problems of unfavorable differential information extraction and expression, accurate qualitative diagnosis of rotor power frequency faults, and neglect of diagnostic information and other issues to achieve the effect of promoting further improvement and development and realizing qualitative diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

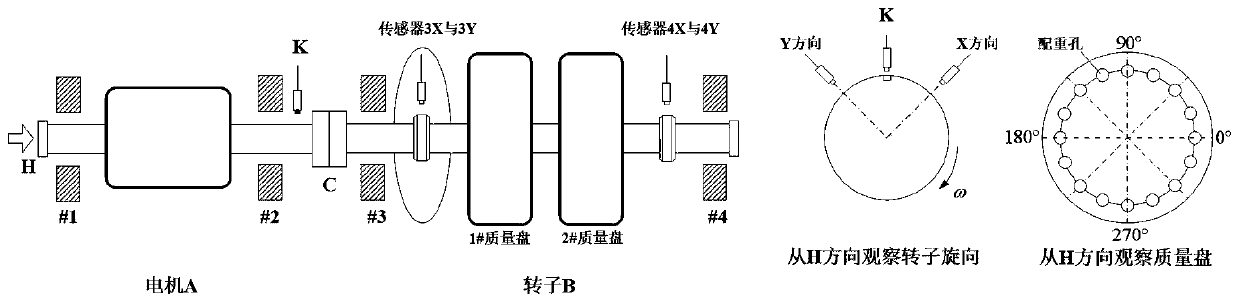

[0023] Embodiment The power frequency fault induced by the rotor unbalance problem is simulated on the Bentley rotor test bench, and its structure diagram is as follows figure 1 As shown: the test bench includes motor A and rotor B. The rotor of motor A is supported by 1# and 2# bearings, and the rotor B is supported by 3# and 4# bearings. The two rotors are connected by flexible coupling C. The 1# and 2# balance plates for adding test weights are symmetrically arranged in the span of the rotor B along the axial direction. 16 threaded holes are equiangularly and evenly distributed on the circumference of a balance plate with a radius of 32mm, which are used to add test weights in the rotor unbalance simulation experiment. Install two vibration sensors perpendicular to each other in the X and Y directions of the vibration measuring belts of the 3# and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com