Device for preventing low-load NOX of circulating fluidized bed boiler from exceeding standard and operation method thereof

A technology of circulating fluidized bed and operation method, which is applied in the field of devices to avoid low-load NOX exceeding the standard of circulating fluidized bed boiler, can solve the problems of low SNCR denitration efficiency, etc. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

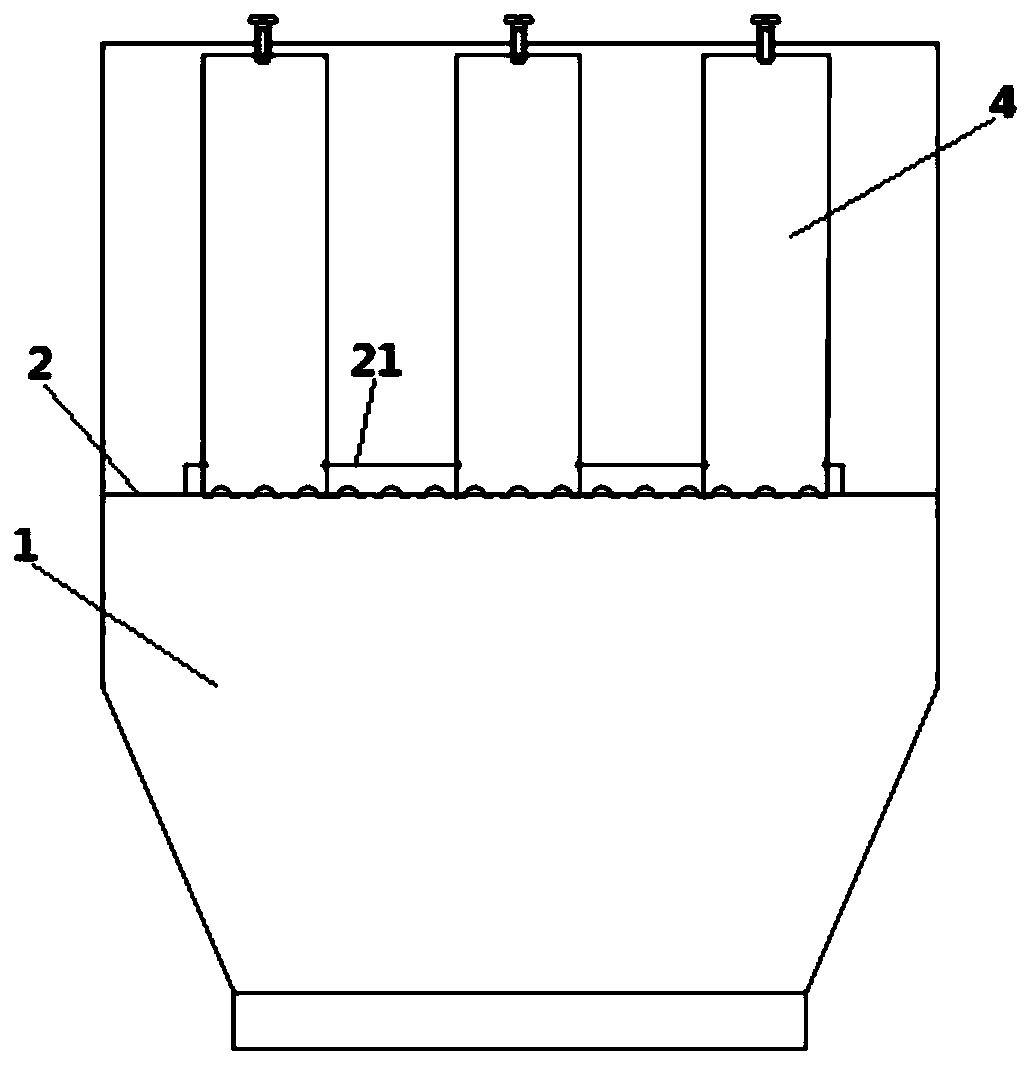

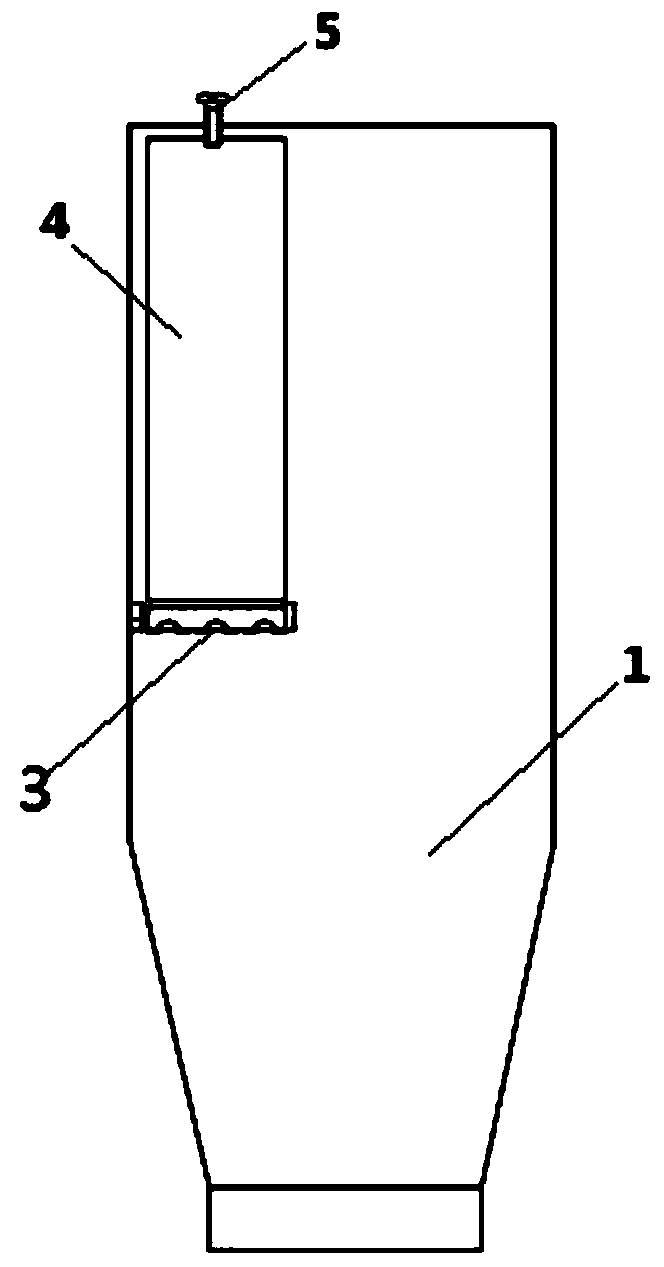

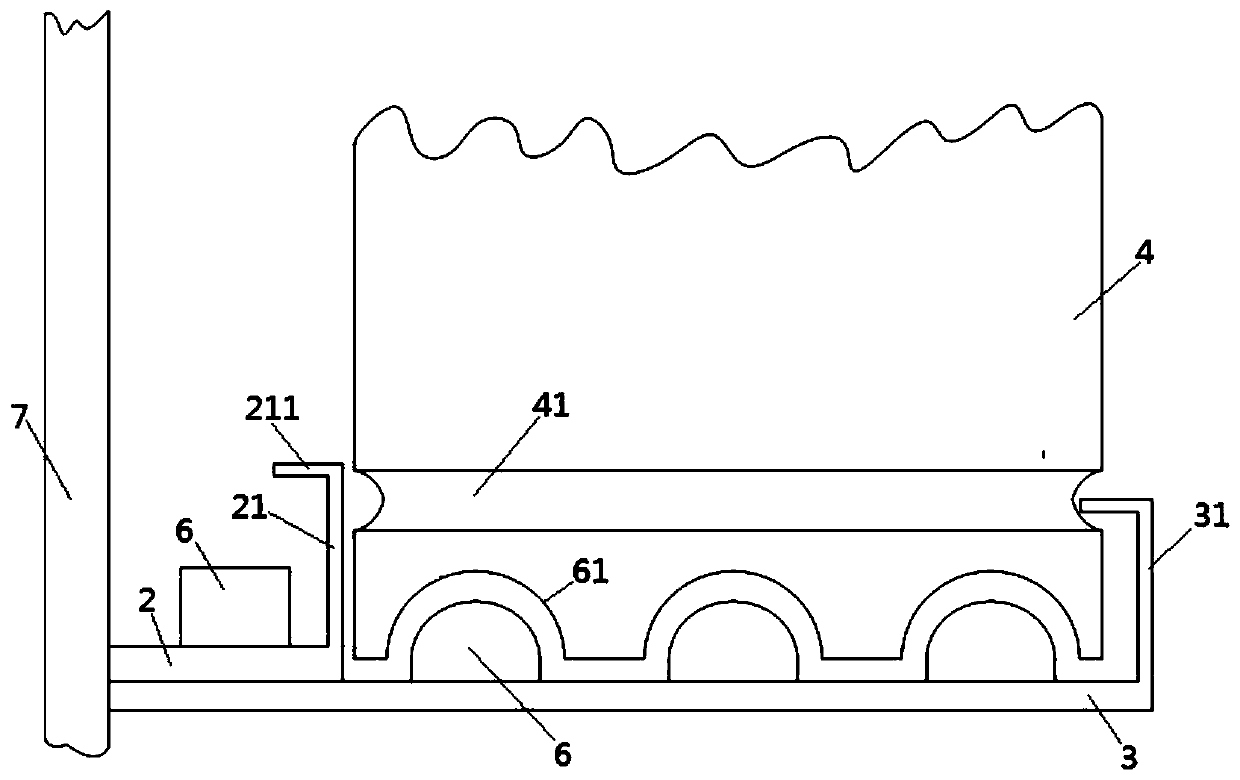

[0031] The present invention provides a device for avoiding excessive NOx under low load of a circulating fluidized bed boiler, which includes a heat shield 4, the top of the heat shield 4 is provided with a connecting piece 5, and the connecting piece 5 runs through the top of the furnace 1. Part 5 drives the heat shield plate 4 to move and rotate. When the plate surface of the heat shield plate 4 is parallel to the water wall, the heat absorbed by the water wall in the furnace 1 is reduced. When the connecting piece 5 is rotated, the plate surface of the heat shield plate 4 is vertical. The water-cooled wall absorbs the heat in the furnace 1.

[0032] In the preferred embodiment of this embodiment, several relief pipes are arranged on the top of the furnace 1, and the slits of the plurality of relief pipes form a plurality of limit openings 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com