Valve for remote fuse control

A fusing and remote technology, applied in the direction of lift valve, valve details, safety valve, etc., can solve problems such as increasing fire safety hazards, fire hazards, and inability to achieve fire protection functions, and achieve stability, safety level improvement, and reliability enhancement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

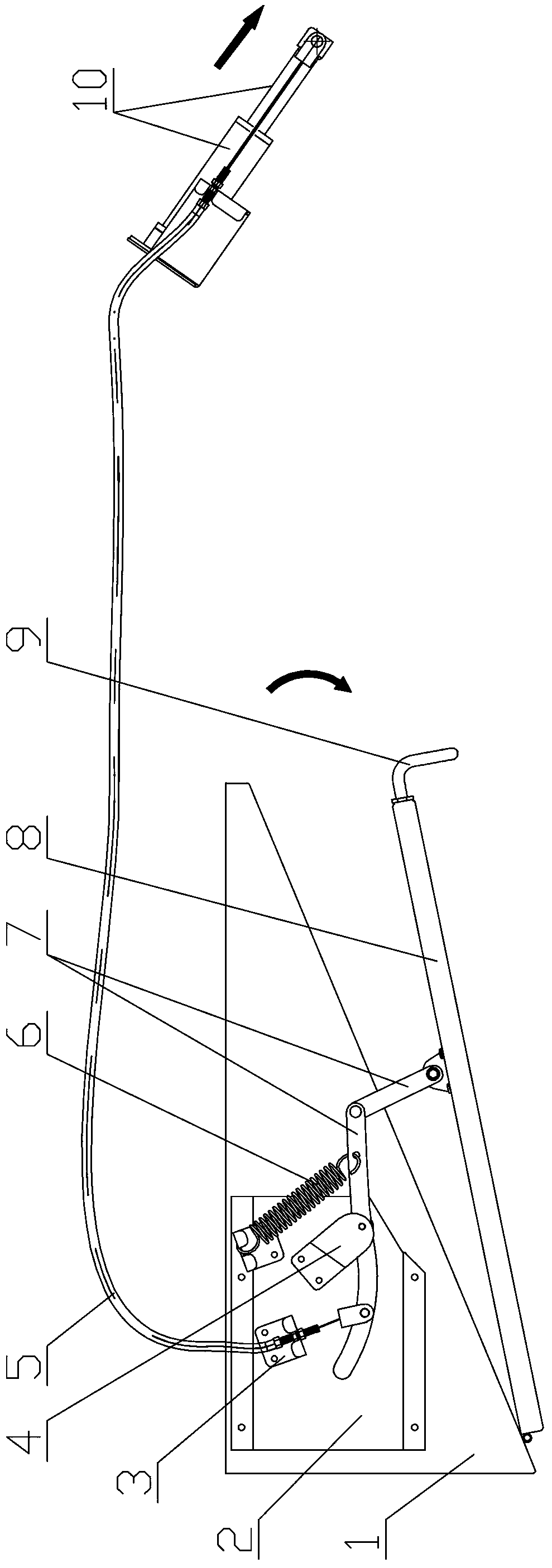

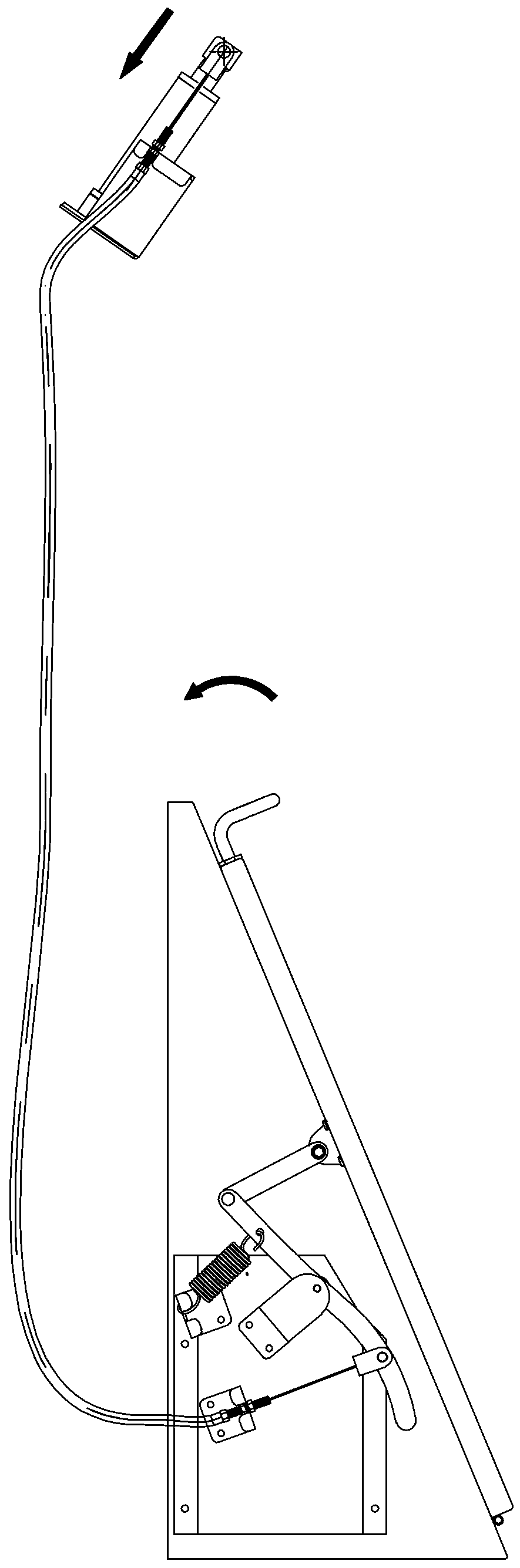

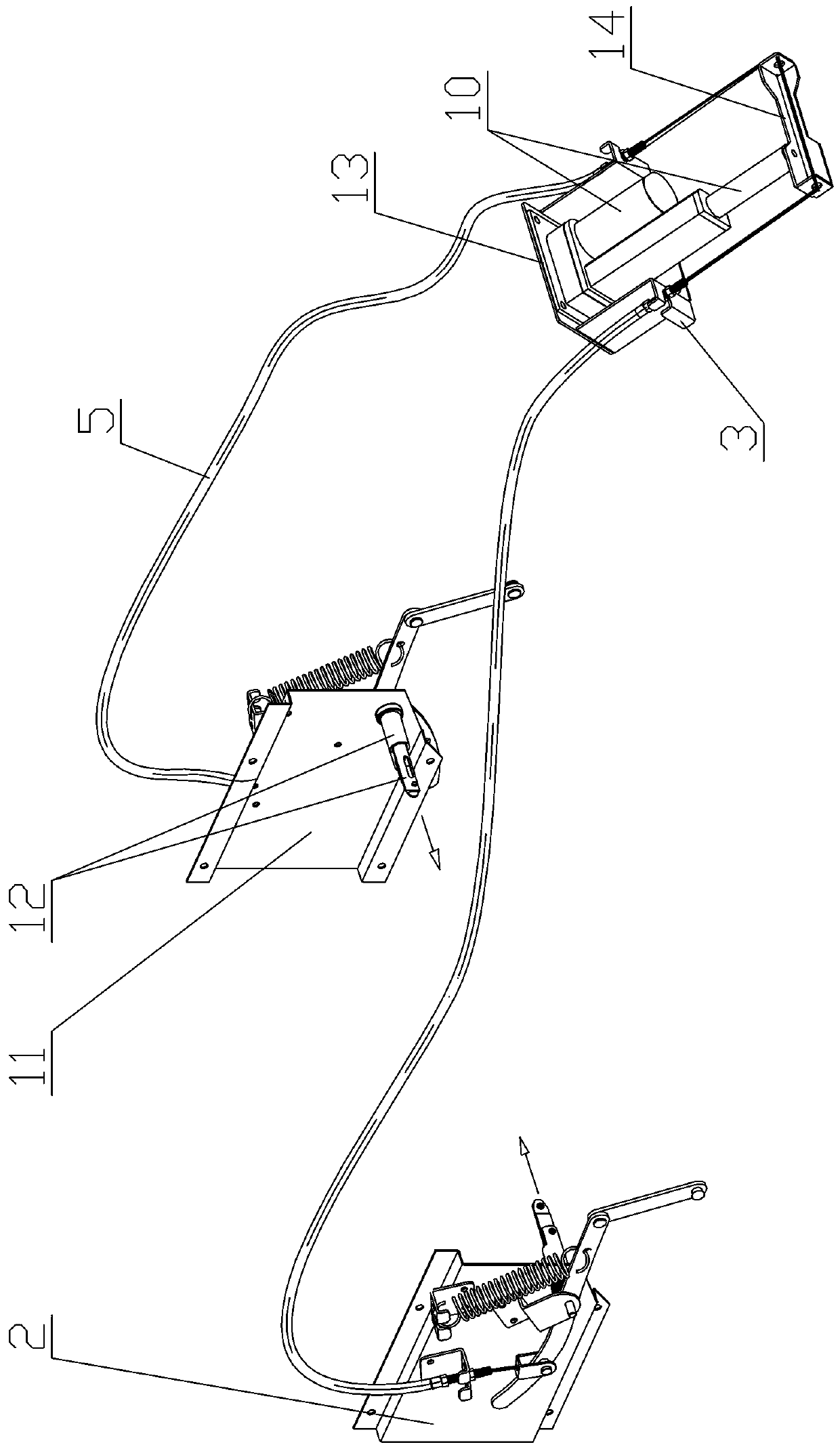

[0020] see Figure 1-Figure 5 , the present invention is a valve for remote fusing control, which has a valve body 1, on which an oblique valve plate 8 is hinged, the bottom end of the oblique valve plate is hingedly connected with the valve body, and the upper end of the oblique valve plate Pulling handle 9 is housed, and left and right connecting rod body 2 and right connecting rod body 11 are respectively arranged on the left and right side outer walls of described valve body, and connecting rod seat plate is all included on left connecting rod body and right connecting rod body, connects The rod seat plate is provided with a nozzle card 3 and an extension spring card 16, and a nozzle coil 15 is mounted on the nozzle card, and a steel cable 5 is installed in the nozzle coil; an extension spring 6 is housed on the extension spring card, The lower end of the extension spring is connected with one or two connecting rods 7, and the front ends of the two connecting rods are hing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com