Anti-collision device of overline T-shaped beam bridge and mounting method thereof

An anti-collision device and cross-line technology, which is applied to road safety devices, bridges, bridge parts, etc., can solve problems such as side main beam damage, and achieve the effects of easy manufacture and installation, easy installation, maintenance and replacement, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

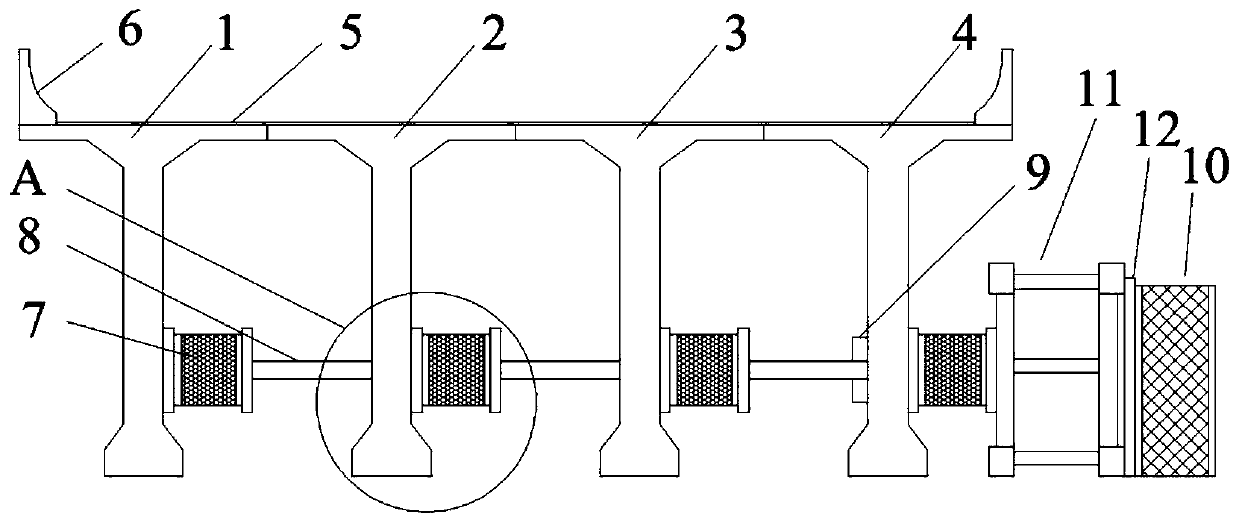

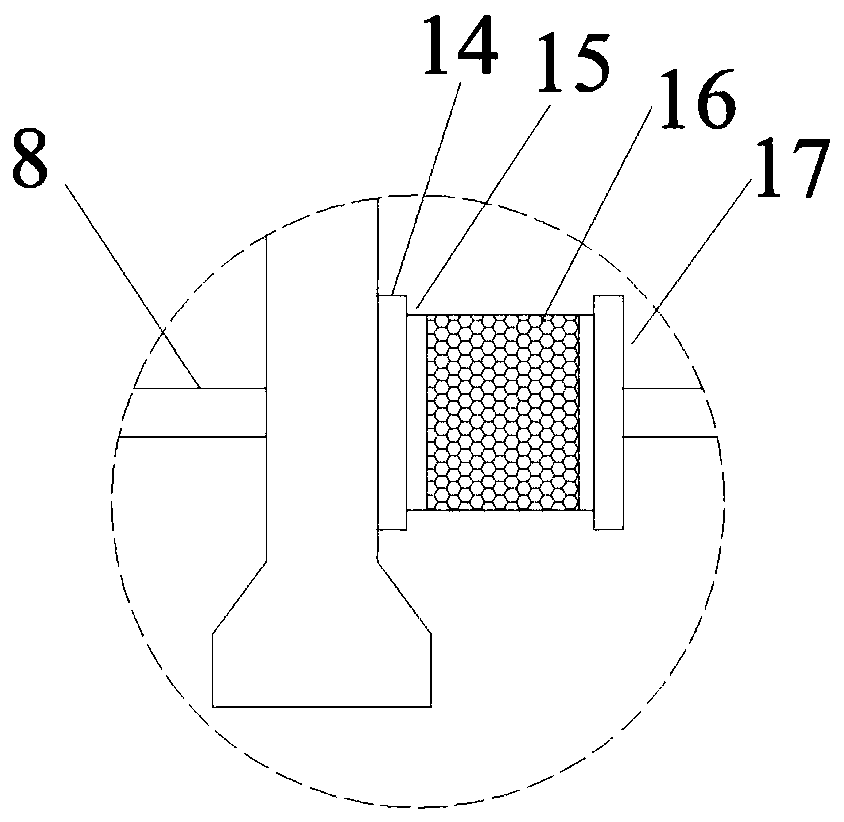

[0048] figure 1 It is a schematic diagram of the front view of the longitudinal bridge of the anti-collision device in this embodiment. The T-beam bridge is a four-beam simply supported T-beam bridge with a span length of 20m and only one-way vehicles. The bridge consists of 4 prefabricated T-beams arranged side by side, and the adjacent upper flanges are connected into one body through on-site wet joints, which can be divided into the first main beam 1, the second main beam 2, the third main beam 3 and the fourth main beam. The beam 4 has a bridge deck layer 5 on it, and reinforced concrete guardrails 6 are arranged on both sides of the bridge deck. The bridge deck layer 5 is composed of 80mm thick C50 concrete, waterproof layer, 100mm thick asphalt concrete from bottom to top, and a 1% transverse slope is provided to one side. The height of the main beam is 1500mm, the overall width is 2000mm, the net distance between each main beam is 1800mm, the width of the web above the...

Embodiment 2

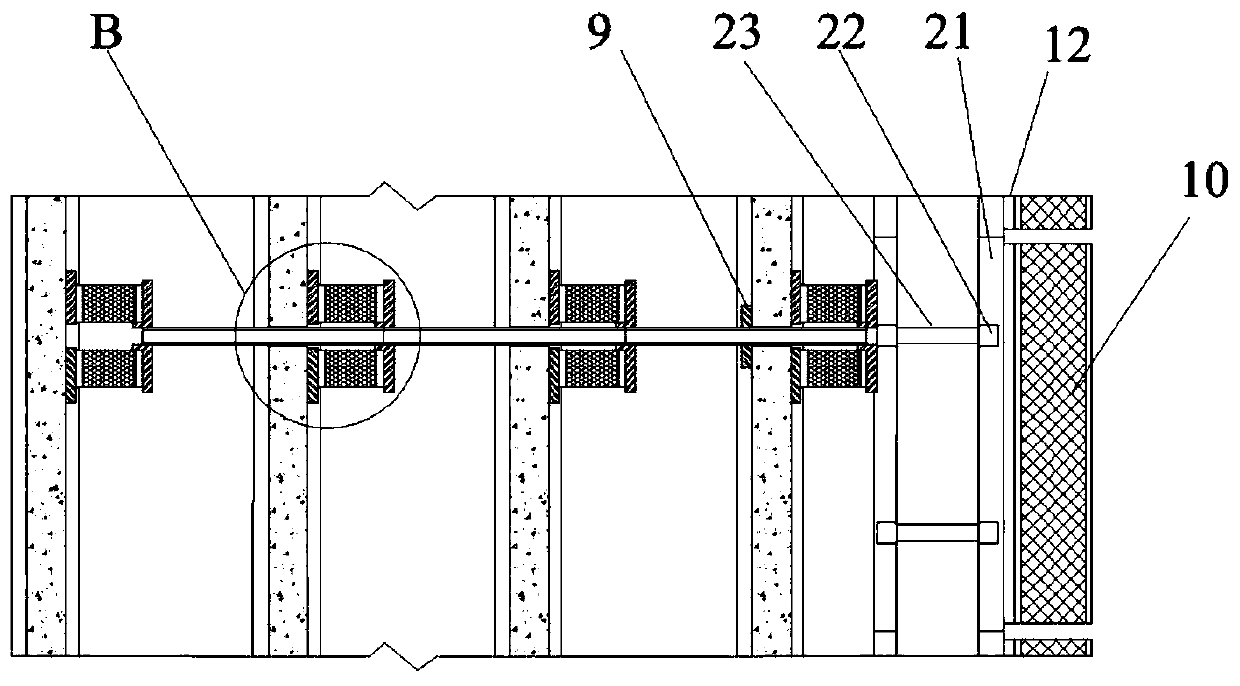

[0059] The difference between this embodiment and Embodiment 1 is that there are two layers of energy-consuming units in the vertical direction. For details, see Figure 12 , to facilitate the consumption of large impact energy. The specification of vertical bar 22 is identical with horizontal bar 21, and length is 800mm, and whole anti-collision frame 11 height is 1000mm. 820mm from the center of the force transmission hole 13 on the upper floor to the bottom surface of the main beam.

Embodiment 3

[0061] The difference between this embodiment and Embodiment 1 is that the number of energy-consuming components 7 of each energy-consuming unit is not equal. For details, see Figure 13 . Considering that the probability of super-high vehicles appearing on the right side of the lower road is greater, the number of energy-consuming components 7 of the corresponding energy-consuming unit is 4, while the number of energy-consuming components 7 of the energy-consuming unit on the other side is gradually reduced to 3 1 and 2, make the anti-collision device more targeted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com