Indoor mixer for asphalt mixture

A technology of asphalt mixture and mixer, which is applied to cleaning methods and appliances, chemical instruments and methods, roads, etc., and can solve problems such as uneven mixing, asphalt air smoke pollution, and inability to mix asphalt mixture in place, so as to improve mixing Uniformity, improved smoke, reduced bitumen loss and weighing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

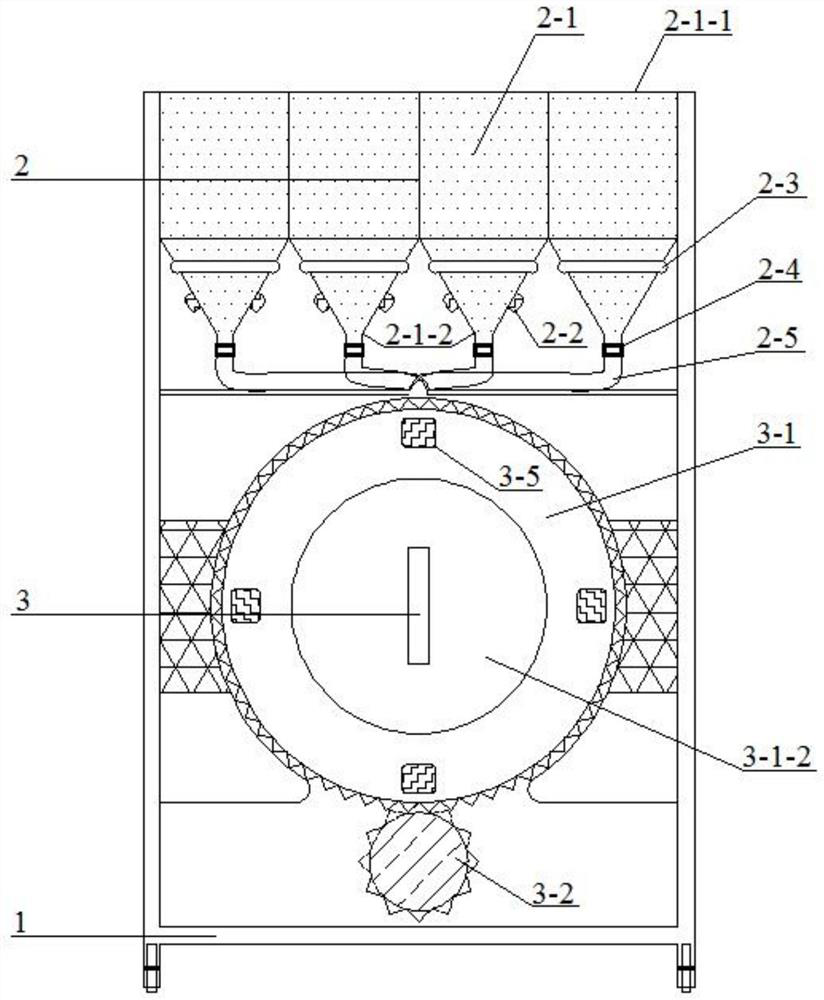

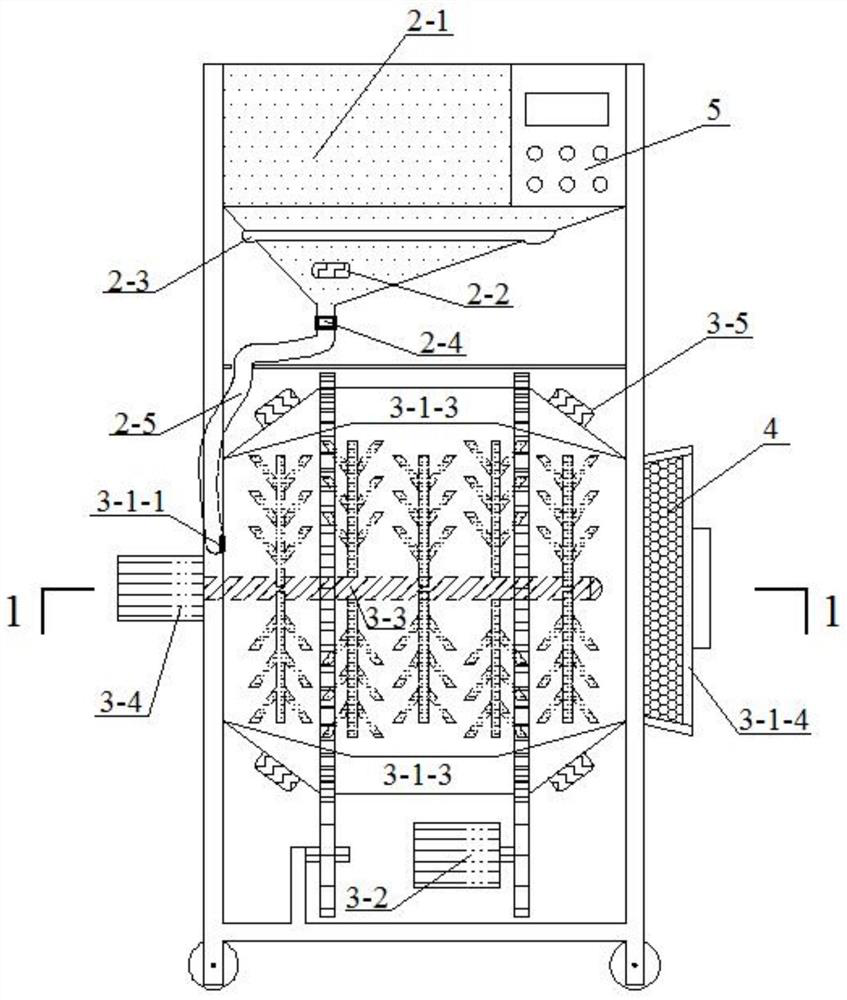

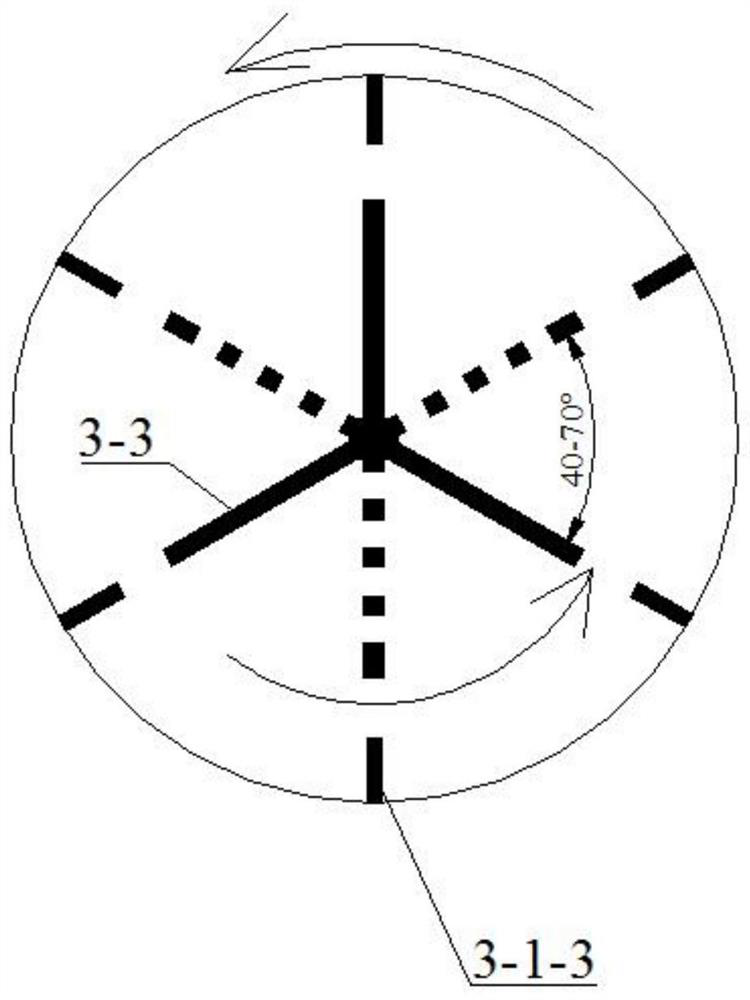

[0053]An indoor mixer for asphalt mixture, comprising a frame 1, a raw material adding device 2, a mixture stirring device 3, an asphalt fume absorbing device 4 and a comprehensive control panel 5; the frame 1 provides a working platform for the auxiliary parts of the mixer , the frame 1 is sequentially provided with the raw material adding device 2 and the mixed material stirring device 3 from top to bottom, the raw material adding device 2 can store and add raw materials, and is installed on the top of the frame 1; The asphalt fume absorbing device 4 is embedded inside the discharge port of the mixture stirring device 3, and the integrated control panel 5 is electrically connected to the raw material adding device 2 and the mixture stirring device 3 respectively. Comprehensive control is carried out; the mixing tank 3-1 in the mixing material stirring device 3 is arranged horizontally, and the horizontal direction is composed of a combination of round table+cylinder+round tab...

experiment example 2

[0076] An indoor mixer device for asphalt mixture is the same as in Embodiment 1, only two adjacent rows of stirring paddles are replaced correspondingly to form an included angle of 30° on the vertical projection plane.

experiment example 3

[0078] An indoor mixer device for asphalt mixture is the same as in Embodiment 1, only two adjacent rows of stirring paddles are replaced correspondingly to form an included angle of 40° on the vertical projection plane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com