Preparation method of super-hydrophobic polylactic acid non-woven material and product

A non-woven material, polylactic acid technology, used in textiles and papermaking, repelling fibers to liquids, fiber processing, etc., can solve the problems of poor durability of interfacial adhesion materials, narrow controllable range, and cumbersome preparation process. The effect of not easy to secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 0.2g PLA was dissolved in 80ml of acetone / ethanol (volume fraction of acetone is 70%) solution, the solution was slowly added dropwise to 500ml of water, mechanically stirred and volatilized at normal temperature for 24h, and PLA nanoparticles were obtained through freeze-drying; , the PLA nonwovens were immersed in absolute ethanol for ultrasonic cleaning and dried at 80 °C. Dissolve 2g of epoxy resin, 2g of polyamide resin (curing agent), and 1g of KH-560 in 35g of ethanol, stir for 0.5 hours, add 6g of the PLA nanoparticles prepared above, stir at a constant speed at 40°C, and dissolve PLA with a thickness of 1mm The nonwoven material was cut into a size of 3cm×3cm (mass 3g), immersed in it, and dried in an oven at 80°C to obtain a superhydrophobic PLA nonwoven material.

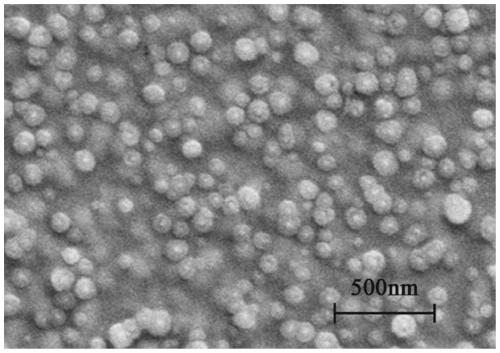

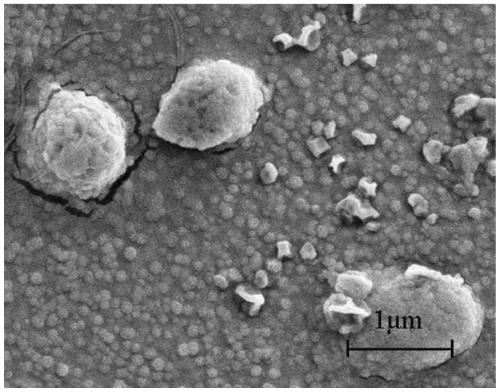

[0042] SEM images for PLA nanoparticles, such as figure 1 As shown, the diameter of PLA nanoparticles is 80-100nm; the static water contact angle of the superhydrophobic PLA nonwoven material is 1...

Embodiment 2

[0044] 0.2g PLA was dissolved in 80ml of acetone / ethanol (volume fraction of acetone is 70%) solution, the solution was slowly added dropwise to 500ml of water, mechanically stirred and volatilized at normal temperature for 24h, and PLA nanoparticles were obtained through freeze-drying; , the PLA nonwovens were immersed in absolute ethanol for ultrasonic cleaning and dried at 80 °C. Dissolve 3g of epoxy resin, 3g of polyamide resin (curing agent), and 1g of KH-560 in 35g of ethanol, stir for 0.5 hours, add 6g of the PLA nanoparticles prepared above, and stir at a constant speed at 50°C. The PLA nonwoven material was cut into a size of 3cm×3cm (mass 3g), immersed in it, and dried in an oven at 80°C to obtain a superhydrophobic PLA nonwoven material.

[0045]The diameter of PLA nanoparticles is 80-100nm; the static water contact angle of the superhydrophobic PLA nonwoven material is 151.1°; the oil absorption rate for castor oil is 548.5%.

Embodiment 3

[0047] 0.2g PLA was dissolved in 80ml of acetone / ethanol (volume fraction of acetone is 70%) solution, the solution was slowly added dropwise to 500ml of water, mechanically stirred and volatilized at normal temperature for 24h, and PLA nanoparticles were obtained through freeze-drying; , the PLA nonwovens were immersed in absolute ethanol for ultrasonic cleaning and dried at 80 °C. Dissolve 4g of epoxy resin, 4g of polyamide resin (curing agent), and 1g of KH-560 in 31g of ethanol, stir for 0.5 hours, add 6g of the PLA nanoparticles prepared above, and stir at a constant speed at 60°C. The PLA nonwoven material was cut into a size of 3cm×3cm (mass 3g), immersed in it, and dried in an oven at 80°C to obtain a superhydrophobic PLA nonwoven material.

[0048] The diameter of PLA nanoparticles is 80-100nm; the static water contact angle of the superhydrophobic PLA nonwoven material is about 152.0°; the oil absorption rate for castor oil is 550.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com