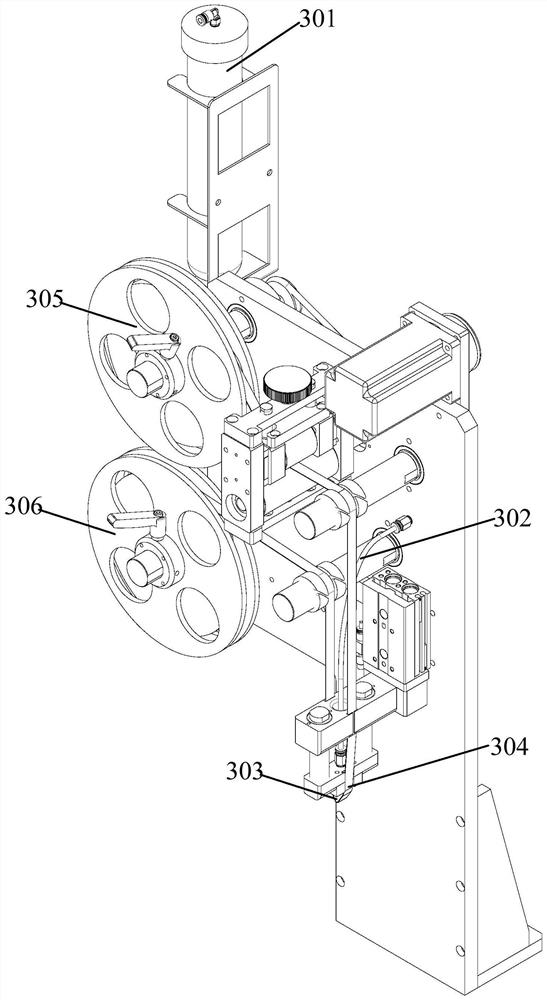

Cleaning and assembling system

An assembly system and cleaning technology, applied in cleaning methods and utensils, cleaning methods using tools, cleaning methods using liquids, etc., can solve problems such as abnormal image display, affecting the imaging effect of the camera, and unclean cleaning of the image sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] As mentioned in the background art, improving the cleaning effect during the assembly process of the lens and the image sensor is an urgent problem to be solved.

[0033] Specifically, the traditional manual wiping method is generally used for cleaning image sensors in the industry, and clean rooms (covering an area of about 40 to 60 square meters) are built with clean rooms of 10,000, 1,000 or 100 levels and cleaned manually, and the cleanness after cleaning is checked. Effect. When manually cleaning the image sensor, dust cleaning around the image sensor is a difficult problem to solve. If the image sensor is cleaned first and then around the image sensor, the dust around the image sensor will fall on the image sensor again, which requires the image sensor to be cleaned again and repeated several times. On the one hand, the cleaning material rate will be reduced. The image sensor is easy to be damaged; if the image sensor is cleaned around the image sensor first, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com