Preparation and use of low-temperature sprayable stripping radioactive contamination remover

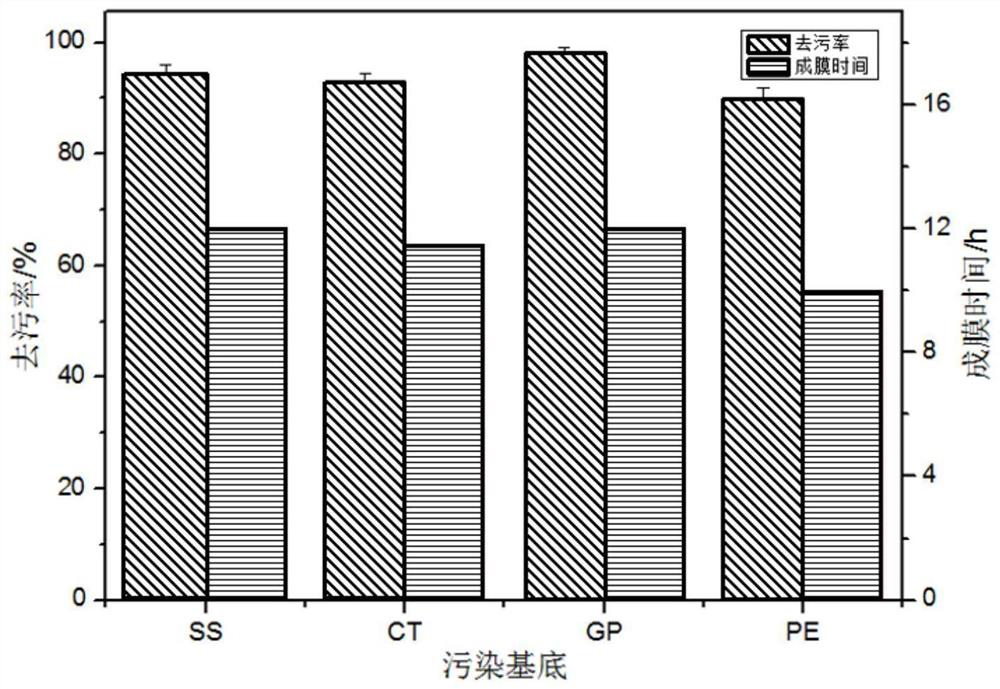

A detergent and stripping technology, which is applied in the field of preparation of low-temperature sprayable stripping radioactive pollution detergent, can solve the problems of poor film mechanical properties, long film forming time, and difficulty in spraying, and achieve film-forming performance Excellent, short film-forming time, improved solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

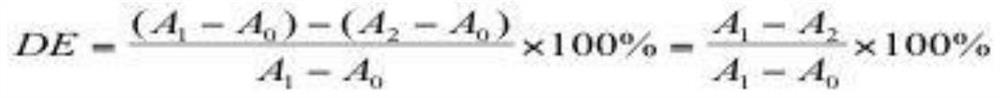

Examples

Embodiment 1

[0029]A preparation method of a low-temperature sprayable stripping type radioactive contamination decontamination agent, comprising the following process: adding 0.5 g of modified biomass and 8 g of polyvinyl acetate into 100 g of solvent I, stirring and dissolving for 10 hours, and then Add 5g bayberry tannin (tannin content≥70%), citric acid, disodium edetate, and sodium dodecylsulfonate (mass ratio 1:1:1:0.1), 0.1g glycerin, stir Dissolved for 6 hours, ultrasonically degassed for 0.5 hours to obtain a detergent; the modified biomass is modified cellulose (see patent document ZL201410446471.5 for the modification method), and its weight ratio to lignin is 1:1; solvent I is the volume Ethanol and water in a ratio of 1:0.1.

[0030] A method for using a low-temperature sprayable peel-off radioactive contamination decontamination agent, comprising: spraying the decontamination agent on the surface of a radioactively contaminated material at -5°C, drying and solidifying to form...

Embodiment 2

[0032] A preparation method of a low-temperature sprayable stripping type radioactive contamination decontamination agent, comprising the following process: adding 8 g of modified biomass and 2 g of polyvinyl butyral to 100 g of solvent I, stirring and dissolving for 12 hours, and then Add 0.5g bayberry tannin (tannin content≥70%), 0.2g stearic acid, stirring and dissolving for 7h, ultrasonic degassing treatment for 0.6h, to obtain detergent; modified biomass is modified cellulose (modification method See patent document ZL201410446471.5), its weight ratio to lignin is 1:1; solvent I is ethanol.

[0033] A method for using a low-temperature sprayable peel-off radioactive contamination decontamination agent, comprising: spraying the decontamination agent on the surface of a radioactively contaminated material at -5°C, drying and solidifying to form a film at -5°C for 14 hours, Peel it off and the decontamination process is complete.

Embodiment 3

[0035] A preparation method of a low-temperature sprayable stripping type radioactive contamination decontamination agent, comprising the following process: adding 0.5 g of modified biomass and 5 g of polyvinyl butyral to 100 g of solvent I, stirring and dissolving for 14 hours, Then add 1g of tea polyphenols and 0.3g of tributyl phosphate, stir and dissolve for 8 hours, and perform ultrasonic degassing treatment for 0.7 hours to obtain a detergent; the modified biomass is modified cellulose (see patent document ZL201410446471.5 for the modification method) , and its weight ratio to lignin is 1:1; solvent I is ethanol and ethyl acetate with a volume ratio of 1:0.1.

[0036] A method for using a low-temperature sprayable peel-off radioactive contamination decontamination agent, comprising: spraying the decontamination agent on the surface of a radioactively contaminated material at -10°C, drying and solidifying to form a film at -10°C for 16 hours, Peel it off and the decontami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com