Phenolic resin and preparation method thereof, and photoresist

A phenolic resin and photoresist technology, applied in the direction of photosensitive materials used in optomechanical equipment, can solve problems such as poor thermal stability, and achieve the effects of good thermal stability, high print resistance, and improved thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] On the other hand, the embodiment of the present invention also provides a preparation method of phenolic resin, the preparation method includes: obtaining reaction raw materials, the reaction raw materials include: p-cresol, m-cresol and phenolic compounds.

[0038] Under the action of an acidic catalyst, the reaction raw materials and formaldehyde are subjected to addition polycondensation reaction to obtain an intermediate product.

[0039] The intermediate product is distilled to obtain phenolic resin.

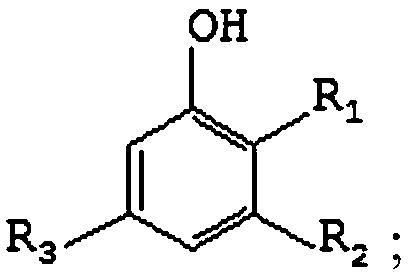

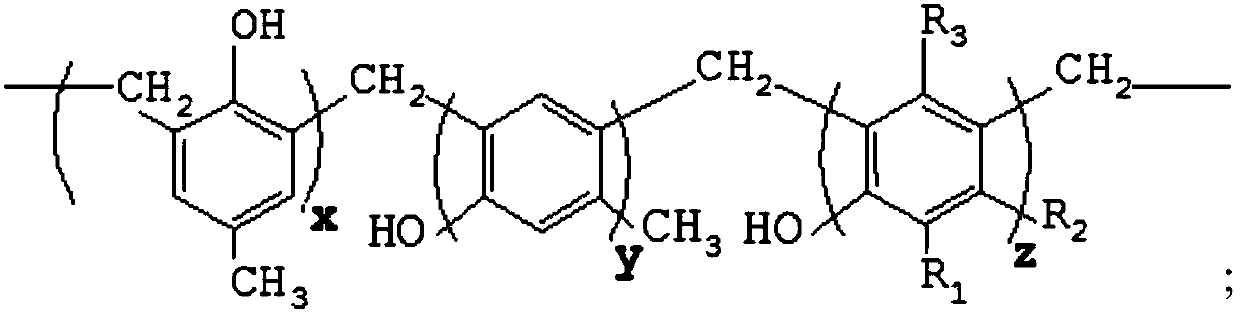

[0040] Wherein, the chemical structural formula of phenolic compound is as follows:

[0041]

[0042] R 1 selected from CH 3 、CH 2 CH 3 or H;

[0043] R 2 and R 3 are selected from H, CH 3 or CH 2 CH 3 .

[0044] For example, the phenolic compound can be o-phenylphenol, whose chemical structural formula is:

[0045] Utilizing the method provided in the embodiments of the present invention, not only can the phenolic resin with the above-mentioned c...

Embodiment 1

[0077] This embodiment provides a phenolic resin, which is prepared by the following method: fully stir and mix 100g p-cresol, 100g m-cresol, 2g o-phenylphenol, and 1.17g oxalic acid, and slowly heat up to 85- At 90°C, 105.08g of formaldehyde aqueous solution (mass concentration: 37%) was slowly added dropwise into the reaction system within 1 hour, and the reaction temperature of the reaction system was controlled at 100°C throughout the process. After the addition of formaldehyde was completed, the reaction was refluxed at 100° C. for 3 h to obtain an intermediate product.

[0078] Then raise the temperature, increase the nitrogen flow rate to 1ml / s, and remove the moisture in the reaction system under normal pressure; after the temperature of the reaction system rises to 160°C, turn on the vacuum pump, the vacuum degree is -0.1MPa, and the decompression stripping system does not completely react Continue to raise the temperature to 200°C and keep it for 2 hours. After confi...

Embodiment 2

[0084] 100g of p-cresol, 100g of m-cresol, 1g of o-phenylphenol, and 1.17g of oxalic acid were fully stirred and mixed, and the temperature was slowly raised to 85-90°C under a nitrogen atmosphere, and 107.08g of formaldehyde aqueous solution (mass concentration: 37%) was mixed in 1h Slowly added dropwise to the reaction system within the whole process, the reaction temperature of the system was controlled at 95°C. After the addition of formaldehyde was completed, the reaction was refluxed at 100° C. for 3 h to obtain an intermediate product.

[0085] Then raise the temperature, increase the nitrogen flow rate to 1ml / s, and remove the moisture in the reaction system under normal pressure; after the temperature of the reaction system rises to 160°C, turn on the vacuum pump, the vacuum degree is -0.095MPa, and the decompression stripping system does not completely react Continue to raise the temperature to 200°C and keep it for 2 hours. After confirming that the phenolic monomer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com