Non-sulfonated temperature-resistant filtrate reducer for drilling fluid, and synthetic method thereof

A fluid loss control agent, non-sulfonic technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of drilling fluid fluid loss control and environmental protection can not have both, to achieve good rheology, resistance to Good salt performance and good filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] 1. A preparation method of an environment-friendly anti-high temperature fluid loss reducer, comprising the following steps:

[0019] (1) Weigh 5g modified nano-SiO 2 Place in a Erlenmeyer flask, add 100ml deionized water to prepare a suspension of nano-silica, stir with a magnetic stirrer at room temperature for 24 hours, and make the modified nano-SiO 2 Fully dispersed to obtain inorganic modified nano-SiO 2 suspension;

[0020] (2) Transfer the above prepared nano-silica suspension to a three-necked flask, and then add AA and DMDAAC with a mass ratio of 3:5 to the flask;

[0021] (3) Adjust the pH value to 7-8 with NaoH solution, turn on the magnetic constant temperature water bath, heat up to 50°C, stir, and pass N into the three-necked flask at the same time 2 30min;

[0022] (4) Stop stirring, add initiator ammonium persulfate and sodium bisulfite to the above-mentioned homogeneous solution, the addition of ammonium persulfate and sodium bisulfite is the same,...

Embodiment 1

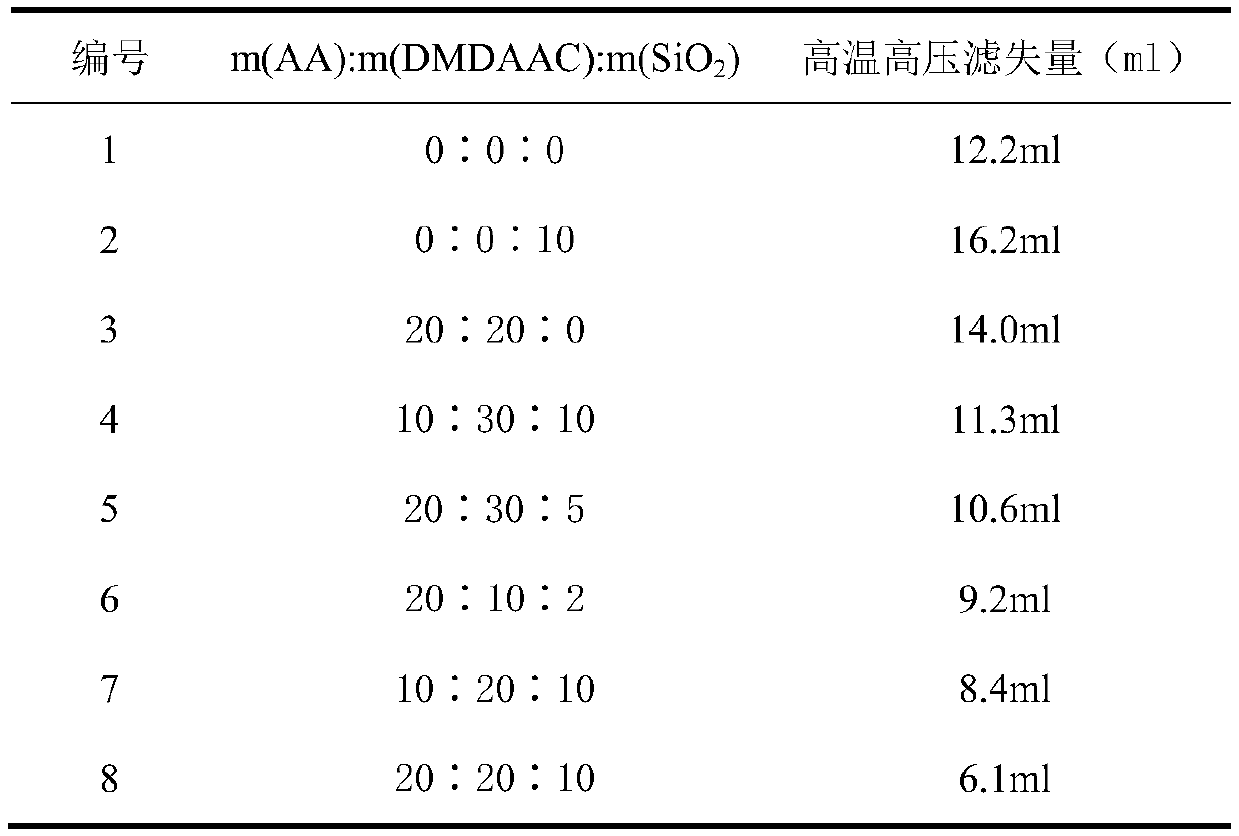

[0044] Example 1: Take the fluid loss reducer with a monomer mass ratio of 2:2:1 and add it to the fresh water base slurry to reduce the fluid loss agent effect at different aging temperatures. The test results are shown in Table 4:

[0045] Table 4 Test results of fluid loss control agent added to freshwater base pulp at different aging temperatures

[0046]

Embodiment 2

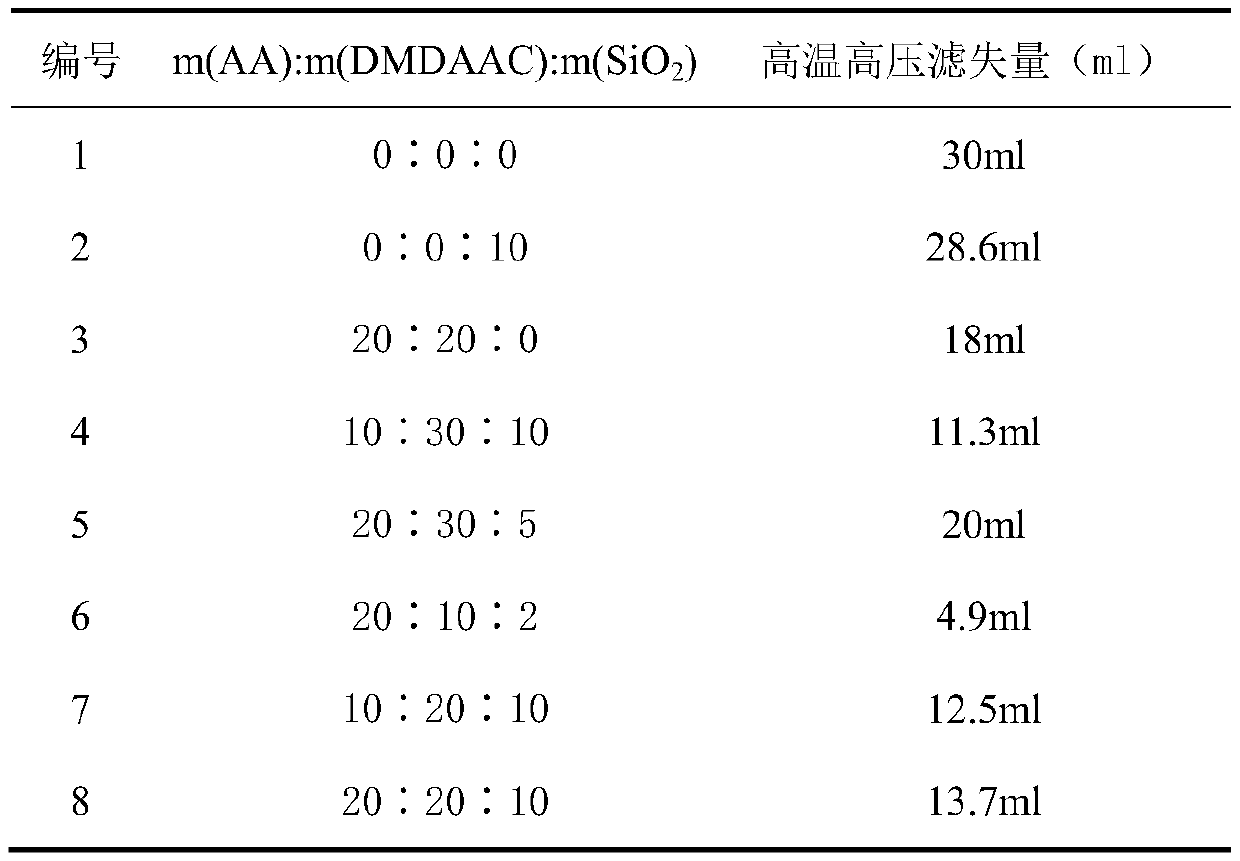

[0047] Example 2: Take the fluid loss reducer with a monomer mass ratio of 10:5:1 and add it to the brine base slurry to reduce the fluid loss agent effect at different aging temperatures. The test results are shown in Table 5:

[0048] Table 5 Test results of fluid loss control agent added to brine-based slurry at different aging temperatures

[0049]

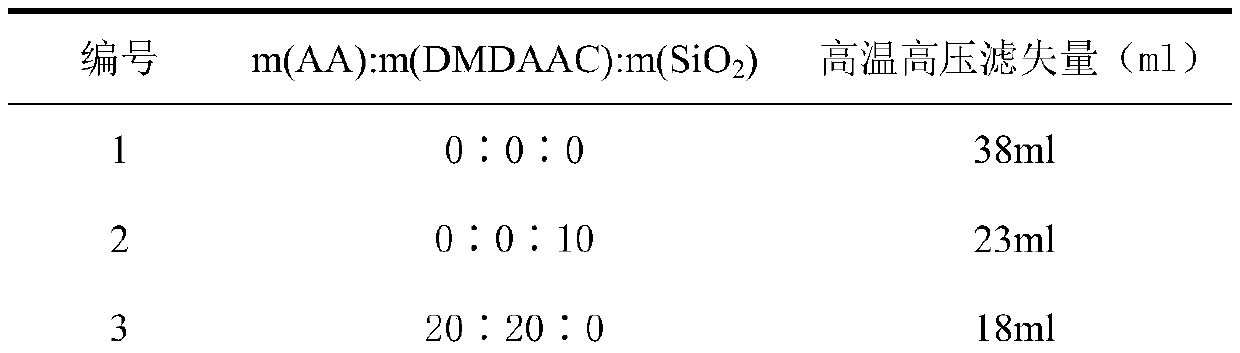

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com