Manganese dioxide/manganese oxide/carbon composite material and preparation method thereof

A technology of carbon composite materials and manganese dioxide, which is applied in the direction of manganese oxide/manganese hydroxide, carbon preparation/purification, electrical components, etc., can solve the problem of single valence state of manganese element, and achieve the purpose of avoiding the appearance and performance, and the preparation The effect of low temperature and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

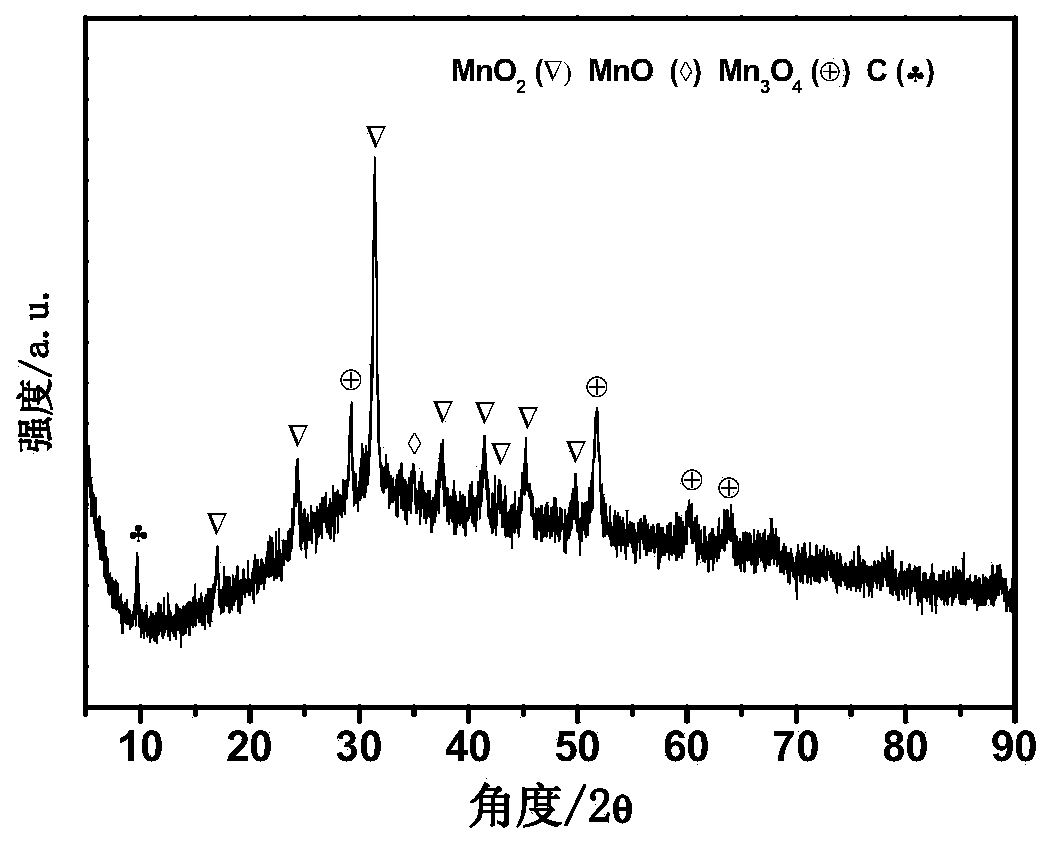

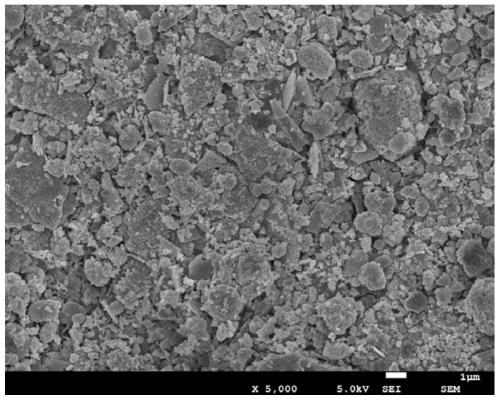

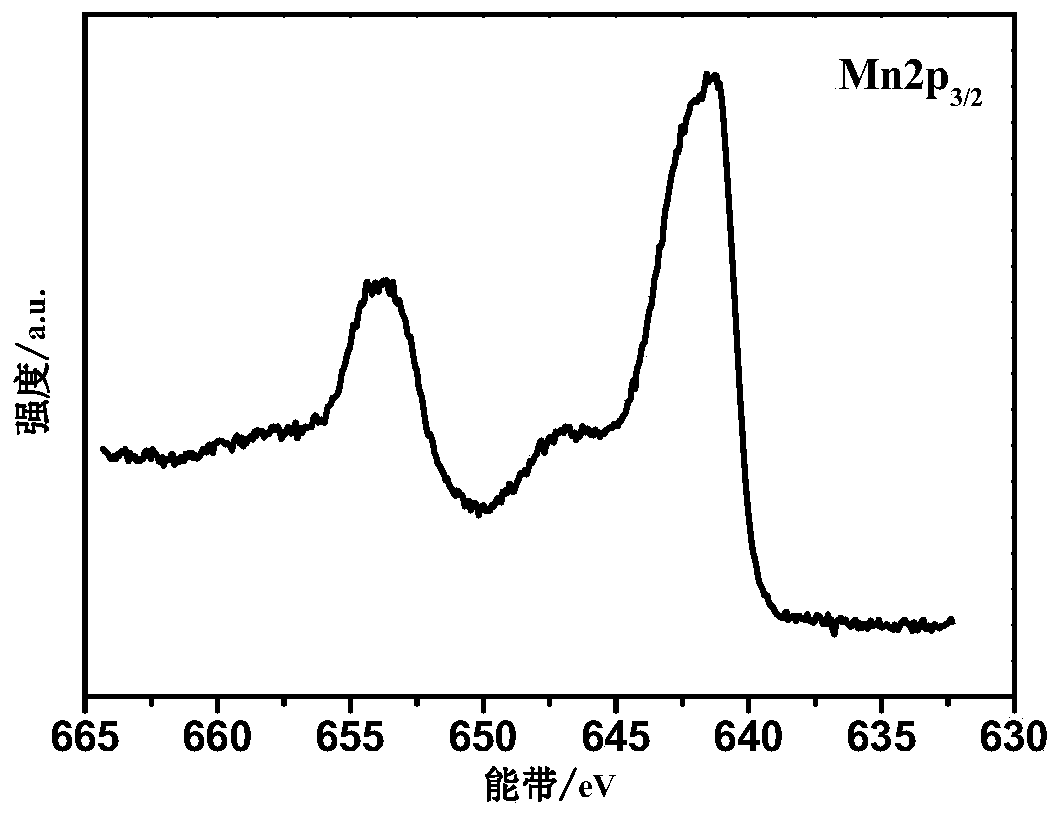

[0058] A manganese dioxide / manganese oxide / carbon composite material is a coating structure, wherein the inner layer material is manganese dioxide material, and the outer layer material is manganese oxide / carbon material.

[0059] A preparation method of manganese dioxide / manganese oxide / carbon composite material, comprising the steps of:

[0060] S1. Cetyltrimethylammonium bromide, n-propanol, and n-hexane are continuously stirred to form solution A, and the mass ratio of cetyltrimethylammonium bromide, n-propanol, and n-hexane is 1 :0.5:0.5;

[0061] S2. Manganese sulfate, aerosol OT, ethanol aqueous solution are formed solution B under continuous stirring, and the mass ratio of the ethanol in manganese sulfate, aerosol OT, ethanol aqueous solution is 5.0 * 10 -4 : 6.2×10 -4 : 0.094, add solution B dropwise to solution A, mix until clear, continue to stir until the second time clear to form microemulsion C, the concentration of manganese sulfate in solution B is 0.0065mol / ...

Embodiment 2

[0065] A manganese dioxide / manganese oxide / carbon composite material is a coating structure, wherein the inner layer material is manganese dioxide material, and the outer layer material is manganese oxide / carbon material.

[0066] The preparation method of this example is the same as that of Example 1, except that the ratio of manganese dioxide, potassium permanganate and glucose in step S4 is 1:0.76:1.90.

Embodiment 3

[0068] A manganese dioxide / manganese oxide / carbon composite material is a coating structure, wherein the inner layer material is manganese dioxide material, and the outer layer material is manganese oxide / carbon material.

[0069] The preparation method of this example is the same as that of Example 1, except that the ratio of manganese dioxide, potassium permanganate and glucose in step S4 is 1:0.46:1.69.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com