Method for precisely controlling boundary dimension of hollow single-crystal turbine moving blade

A technology of precise control of the shape and size, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of airfoil profile, torsion angle, and position tolerance, so as to avoid damage, Avoid multiple size measurements and repeated grinding and polishing, and improve the effect of development and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

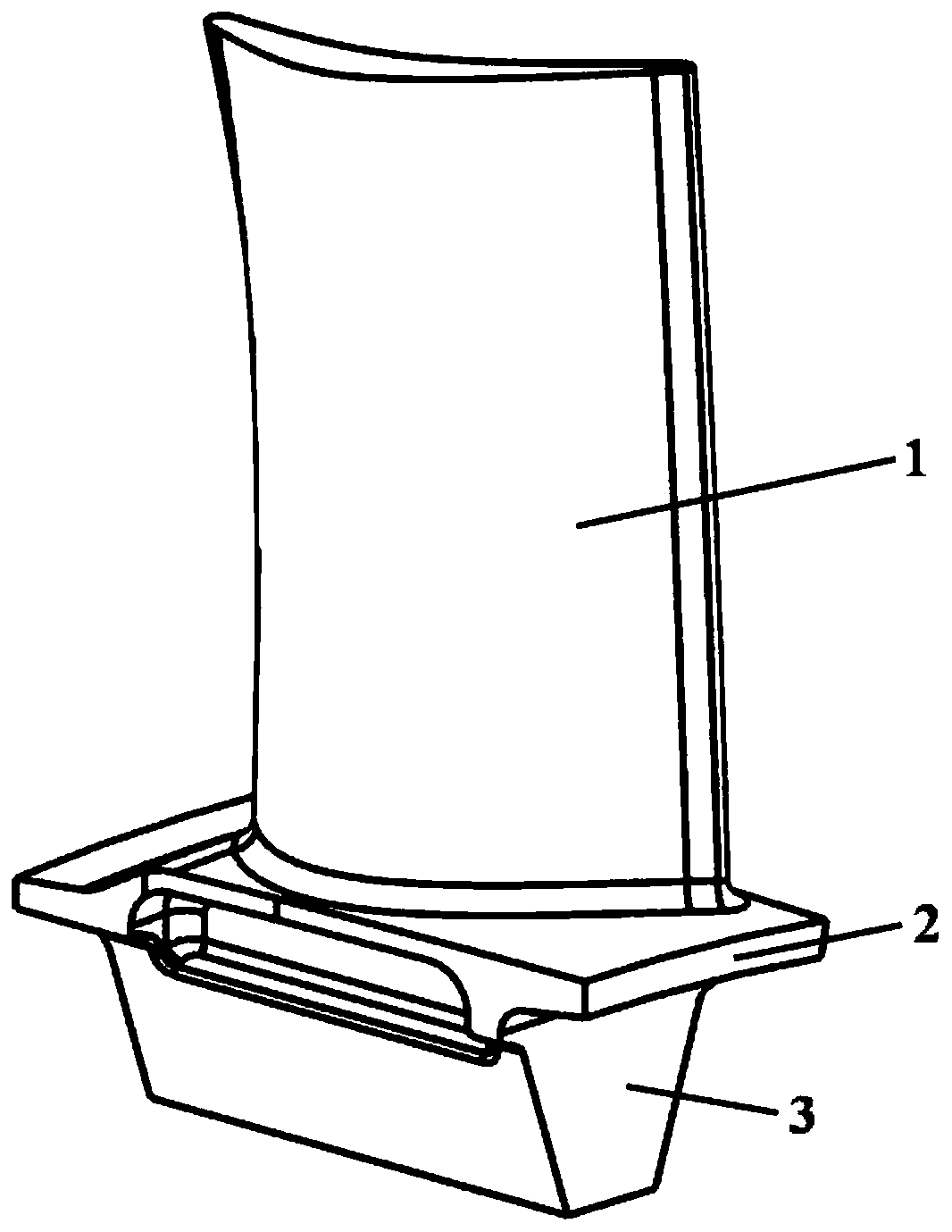

[0025] See attached figure 1 As shown, in this implementation, the hollow single crystal turbine working blade is taken as an example. The casting has the characteristics of compound bending and twisting of the blade body 1, and the wall thickness is thin, and the blade edge plate 2 and tenon 3 are thick. According to the requirements of the drawing, when designing the shape mold of the working blade of a single crystal turbine, the blade body is taken as one part, and the blade edge plate and tenon are taken as the other part, and the shrinkage coefficients are set respectively, specifically: the blade body 1 shrinks in the direction of the stacking axis The coefficient is 1.4%, the shrinkage coefficient of blade edge plate 2 and tenon 3 in the direction of stacking axis is 1.8%, the shrinkage coefficient of blade edge plate 2 and tenon 3 in the direction of stacking axis-the shrinkage coefficient of blade body 1 in the direction of stacking axis= 0.4%.

[0026] Using the sh...

Embodiment 2

[0028] See attached figure 1 As shown, in this implementation, the hollow single crystal turbine working blade is taken as an example. The casting has the characteristics of compound bending and twisting of the blade body 1, and the wall thickness is thin, and the blade edge plate 2 and tenon 3 are thick. According to the requirements of the drawing, when designing the shape mold of the working blade of a single crystal turbine, the blade body is taken as one part, and the blade edge plate and tenon are taken as the other part, and the shrinkage coefficients are set respectively.

[0029] Specifically: the shrinkage coefficient of the blade body 1 in the stacking axis direction is 1.6%, the shrinkage coefficient of the blade edge plate 2 and the tenon 3 in the stacking axis direction is 1.6%, and the positions of the blade edge plate and the tenon are along the blade stacking axis The direction of blade body moves 0.15mm.

[0030] Adopting the method for precise control of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage factor | aaaaa | aaaaa |

| shrinkage factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com