A low carbon monoxide miniature hydrogen generation device using methanol steam reforming

A technology of steam reforming and carbon monoxide, applied in hydrogen/synthesis gas production, hydrogen, inorganic chemistry, etc., can solve the problems of insufficient portability and poor hydrogen production effect, and achieve easy integration, compact structure, and high methanol conversion rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

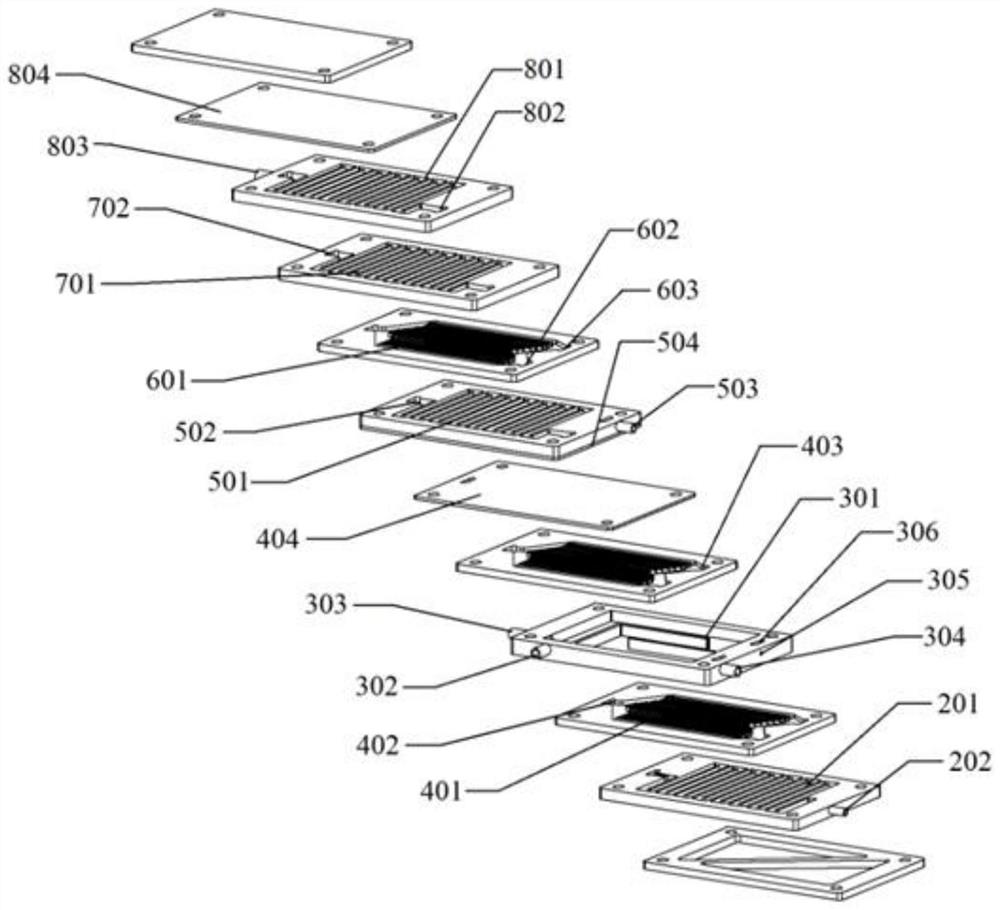

[0021] Specific implementation mode one: combine Figure 1 to Figure 8 Describe this embodiment mode, a kind of low-carbon monoxide micro-hydrogen generation device utilizing methanol steam reforming described in this embodiment mode includes lower end plate 1, gasification layer 2, combustion layer 3, two reforming layers 4, cooling layer 5, CO oxidation layer 6, drying layer 7, CO adsorption layer 8 and upper end plate 9, said lower end plate 1, gasification layer 2, two reforming layers 4, cooling layer 5, CO oxidation layer 6, drying layer 7, CO The adsorption layer 8 and the upper end plate 9 are sequentially stacked and connected from bottom to top, and the combustion layer 3 is arranged horizontally between the two reforming layers 4 .

specific Embodiment approach 2

[0022] Specific implementation mode two: combination Figure 1 to Figure 2 Describe this embodiment, the lower end plate 1, the gasification layer 2, the combustion layer 3, the two reforming layers 4, the cooling layer 5, the CO oxidation layer 6, the drying layer 7, the CO adsorption layer 8 and the upper end plate described in this embodiment Plates 9 are all rectangular plates with the same length and width. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

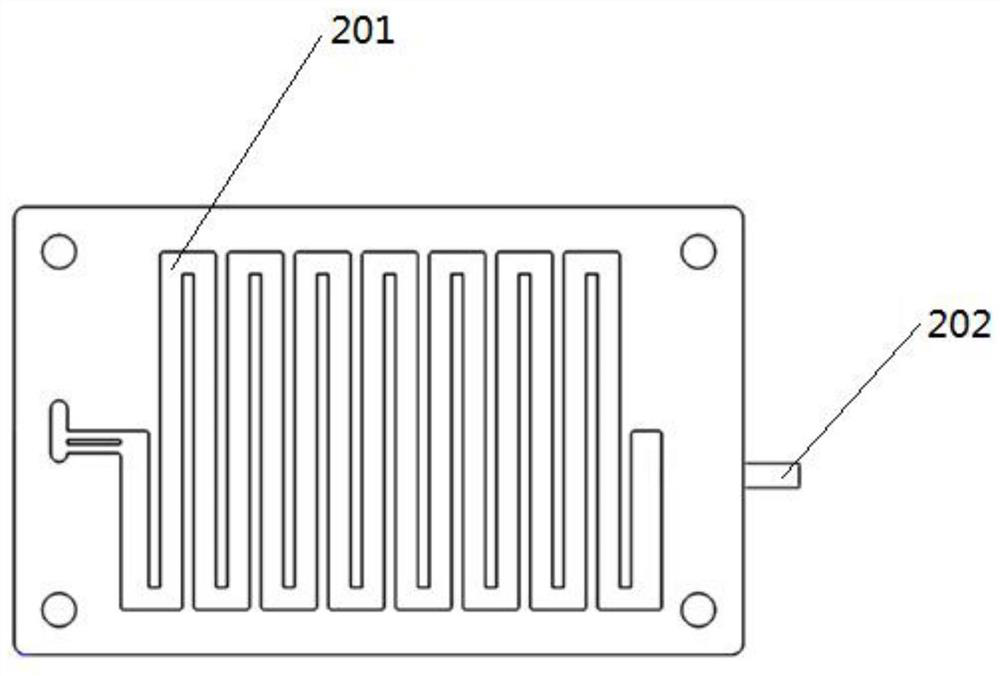

[0023] Specific implementation mode three: combination figure 2 and image 3 To describe this embodiment, the upper surface of the gasification layer 2 in this embodiment is provided with a gasification channel 201 , and one side wall of the gasification layer 2 is provided with a reforming raw material inlet hole 202 . The other components are the same as those in Embodiment 1 or 2 in terms of connections.

[0024] Specific implementation mode four: combination figure 2 and Figure 4 Describe this embodiment, the upper surface of combustion layer 3 described in this embodiment is provided with combustion cavity 301, and the outer wall of combustion layer 3 length direction is provided with fuel liquid inlet hole 302, and one side wall of combustion layer 3 width direction is provided with combustion-supporting chamber. The agent inlet 303, the other side wall of the combustion layer 3 in the width direction is provided with a combustion chamber fluid outlet 304 and a tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com