Hybrid power coupling system and vehicle

A hybrid and coupling system technology, applied in hybrid vehicles, motor vehicles, power units, etc., can solve problems such as insufficient power and economy, and achieve the effects of simple structure, high transmission efficiency, and reduced number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

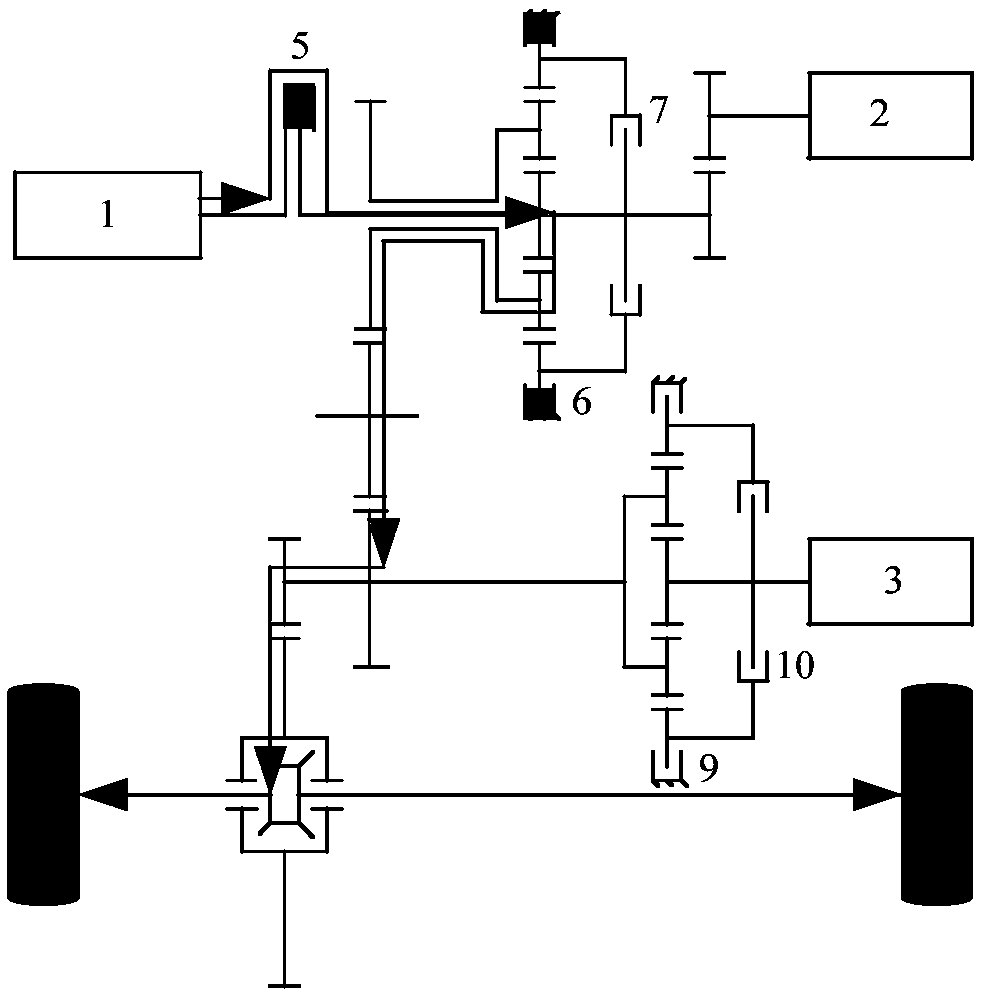

[0086] When the generator 2 is connected to the first sun gear shaft 41 and provided with the second planetary gear mechanism 8 and the first clutch 5, the hybrid power coupling system has an engine direct drive mode (with two gears: the first engine direct drive mode, the second Two-engine direct drive mode), hybrid drive mode (with four types: the first hybrid drive mode, the second hybrid drive mode, the third hybrid drive mode, and the fourth hybrid drive mode), dual-motor pure electric drive mode (with four gears : The first dual-motor pure electric mode, the second dual-motor pure electric mode, the third dual-motor pure electric mode, the fourth dual-motor pure electric mode), single-motor pure electric mode (with two gears: the first single-motor pure electric mode mode, the second single-motor pure electric mode), and series range-extending mode (with two gears: the first series-extending mode and the second series-extending mode) and other five working modes;

[0087...

Embodiment 2

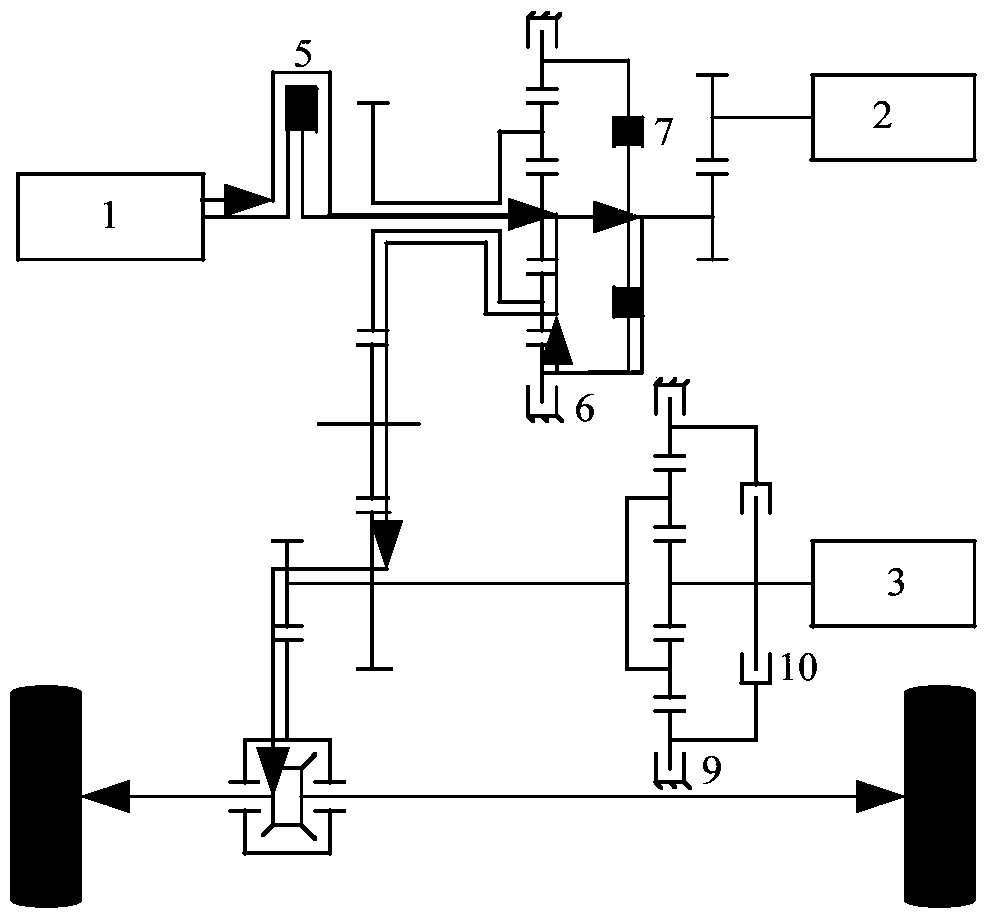

[0173] When the generator 2 is connected with the first ring gear 45 and provided with the second planetary gear mechanism 8 and the first clutch 5, the hybrid power coupling system has an engine direct drive mode (with two gears: the first engine direct drive mode, the second Two-engine direct drive mode), hybrid drive mode (with two gears: the third hybrid drive mode, the fourth hybrid drive mode), dual-motor pure electric drive mode (with two gears: the third dual-motor pure electric mode, the fourth dual-motor Motor pure electric mode), single motor pure electric mode (with two gears: the first single motor pure electric mode, the second single motor pure electric mode), and series range-extended mode (with two gears: first series range-extended mode and The second series extended range mode) and other five working modes;

[0174] Among them, the aforementioned five working modes are shown in Table 2.

[0175] Table 2

[0176]

[0177] The accompanying drawings of thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com