Spline tension positioning device for gear machining and detection and installation method thereof

A positioning device and spline technology, applied in the field of gear processing, can solve problems such as unfavorable processing efficiency, and achieve the effect of simple structure, convenient clamping and fewer components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the drawings and specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

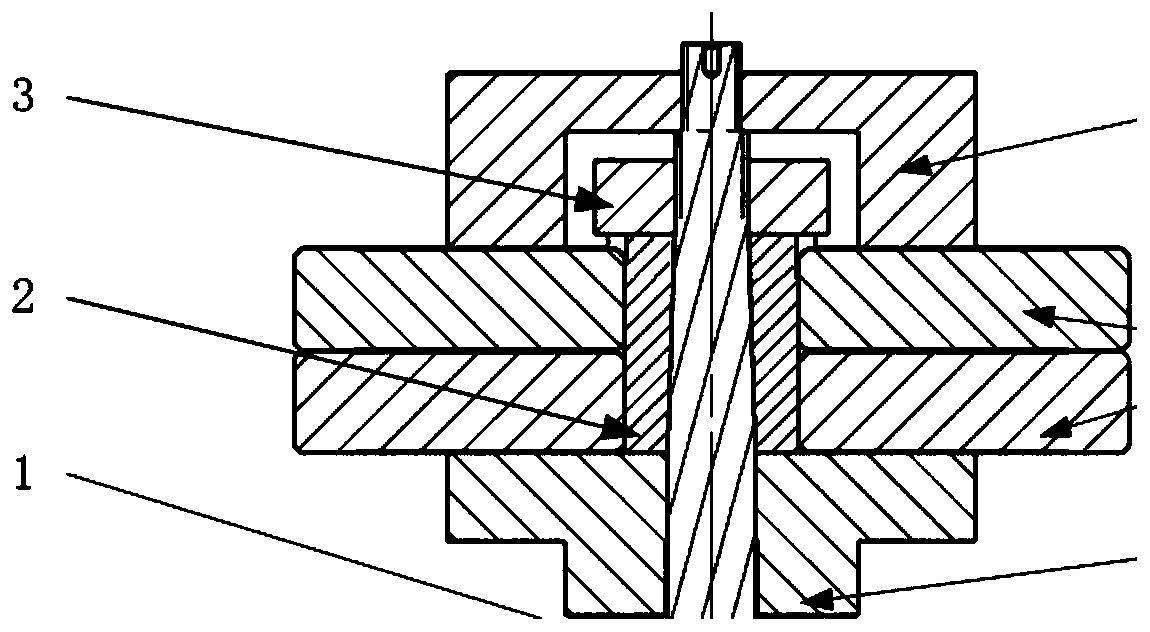

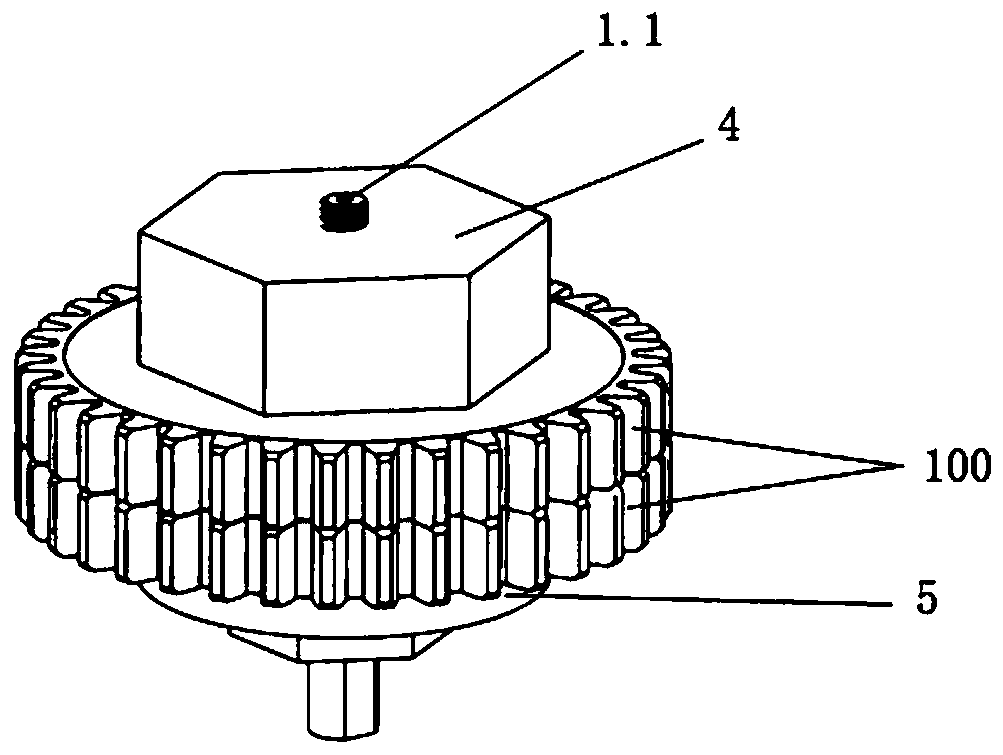

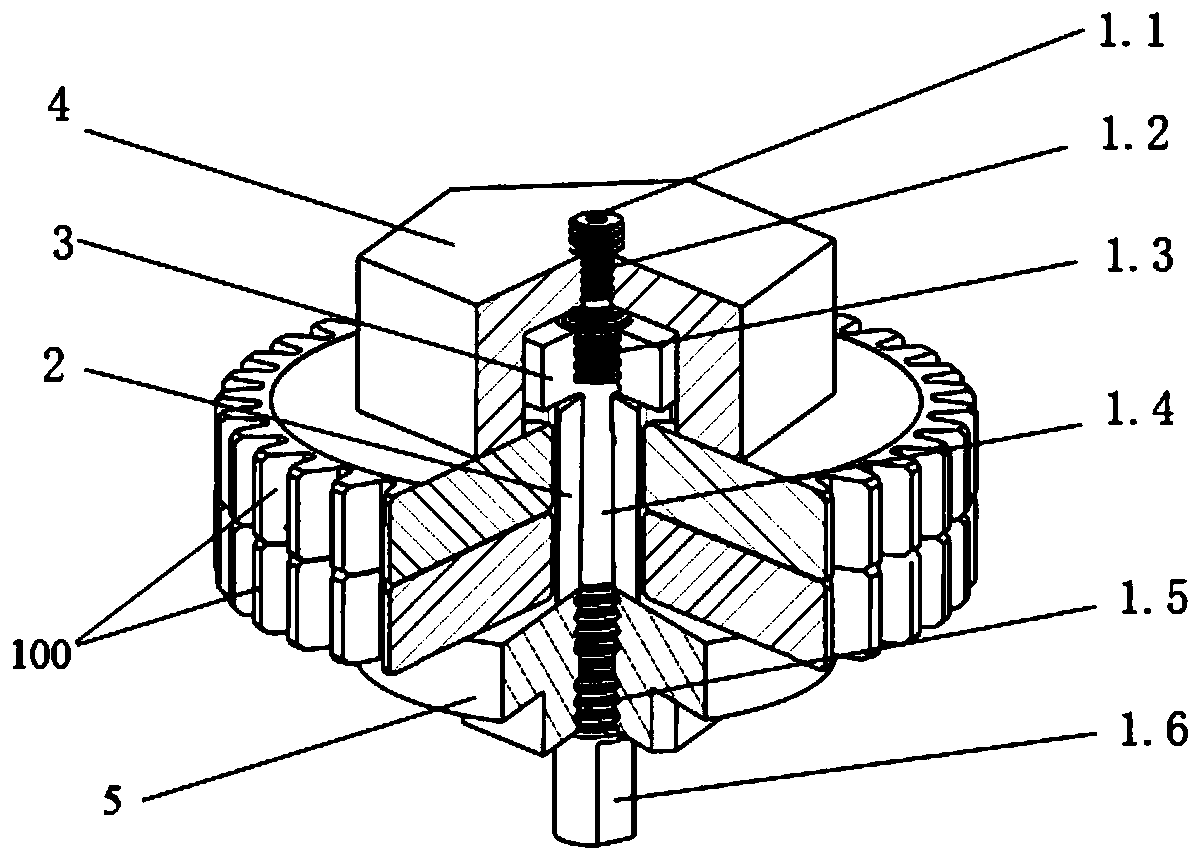

[0021] A spline tightening and positioning device for gear processing and testing, see Figure 1-3 , The device is composed of a mandrel 1, a supporting plate 5, a spline tensioner 2, a set nut 3, a compression nut 4 and other components. It can be realized that the external tooth shape of the part and the center and phase of the internal spline can be clamped at one time, and jointly defined, so as to achieve the purpose of precise positioning and pressing.

[0022] The upper and lower ends of the mandrel are provided with a central positioning hole 1.1, which can cooperate with the double tops of the machine tool and the measuring instrument to perform precise positioning. The upper, middle and lower parts of the mandrel ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com