A method for laser additive manufacturing of titanium alloy monolithic components with gradient structure

A technology of gradient structure and integral components, which is applied in the preparation of gradient structure titanium alloy integral components and the field of laser additive manufacturing of gradient structure titanium alloy integral components, can solve the problems of complex laser additive manufacturing process and many influencing factors, and achieve mechanical The effect of controllable performance, simple process and low-cost manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment specifically discloses a method for laser additively manufacturing a titanium alloy integral component with a gradient structure, and the implementation steps are as follows:

[0032] Step 1: Given any amount of powder feeding (5g / min), conduct preliminary process optimization on the sample of the single deposition layer to obtain laser power (1000W), spot diameter (3mm), scanning speed (10mm / s), etc. other process parameters.

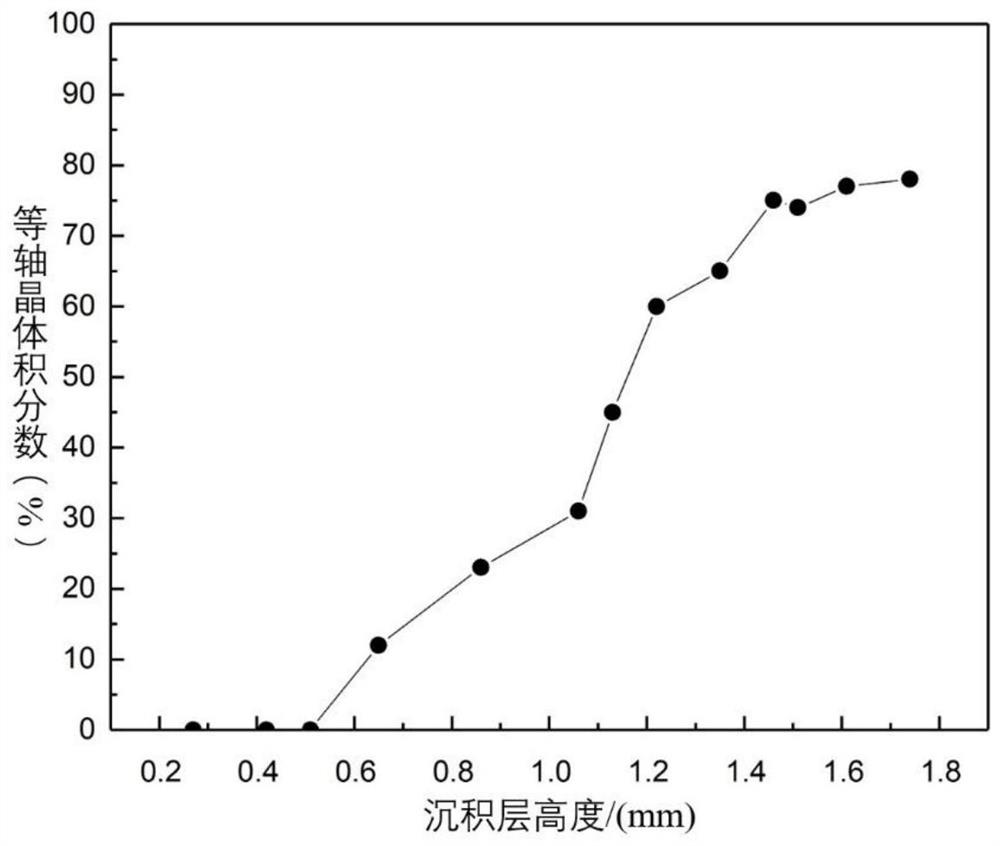

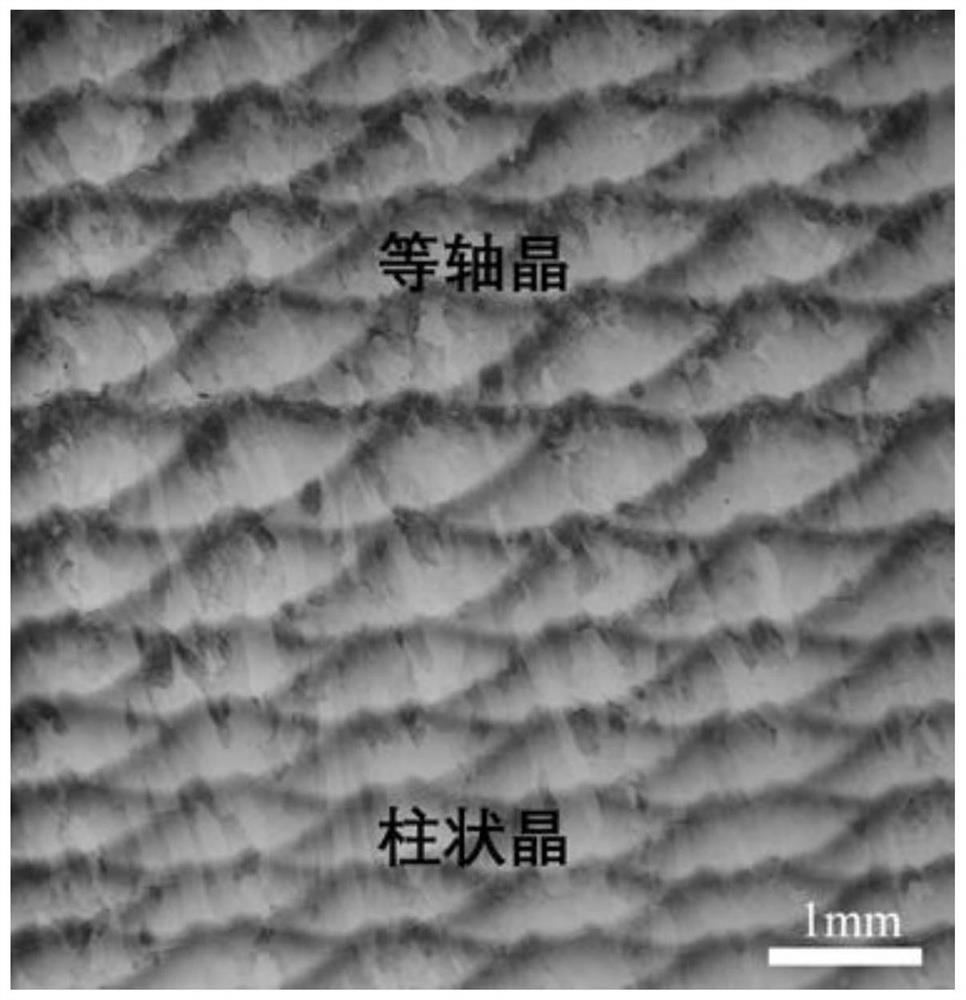

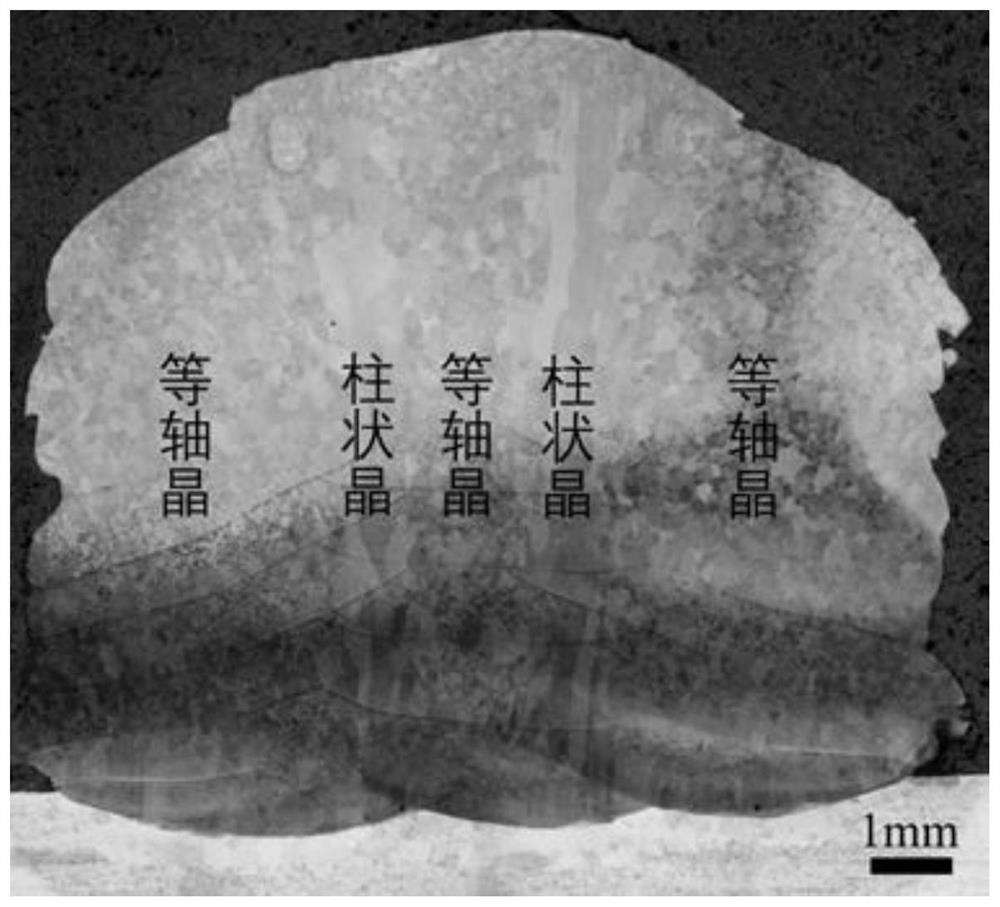

[0033] The second step: further adjust the powder feeding amount on the basis of the primary selection process parameters. The adjustment range is from 1g / min to 25g / min, and different powder feeding rates are selected for the preparation of single-pass deposition layer samples. Measure the height of a single deposition layer under different process parameters and carry out metallographic inspection, and establish a relationship curve between the height of the deposition layer and the integral fraction of equiaxed crystals, such...

Embodiment 2

[0037] This embodiment specifically discloses another method for laser additively manufacturing a titanium alloy integral component with a gradient structure, and the implementation steps are as follows:

[0038] Step 1: Given any amount of powder feeding (5g / min), conduct preliminary process optimization on the sample of the single deposition layer to obtain laser power (1000W), spot diameter (3mm), scanning speed (10mm / s), etc. other process parameters.

[0039] The second step: further adjust the powder feeding amount on the basis of the primary selection process parameters. The adjustment range is from 1g / min to 25g / min, and different powder feeding rates are selected for the preparation of single-pass deposition layer samples. Measure the height of a single deposition layer under different process parameters and carry out metallographic inspection, and establish a relationship curve between the height of the deposition layer and the integral fraction of equiaxed crystals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com