Flue gas desulfurization system and flue gas desulfurization method

A desulfurization system and flue gas technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as process pipeline blockage accidents, high energy consumption, and low competitiveness of sodium sulfite, so as to achieve economic benefits and reduce Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

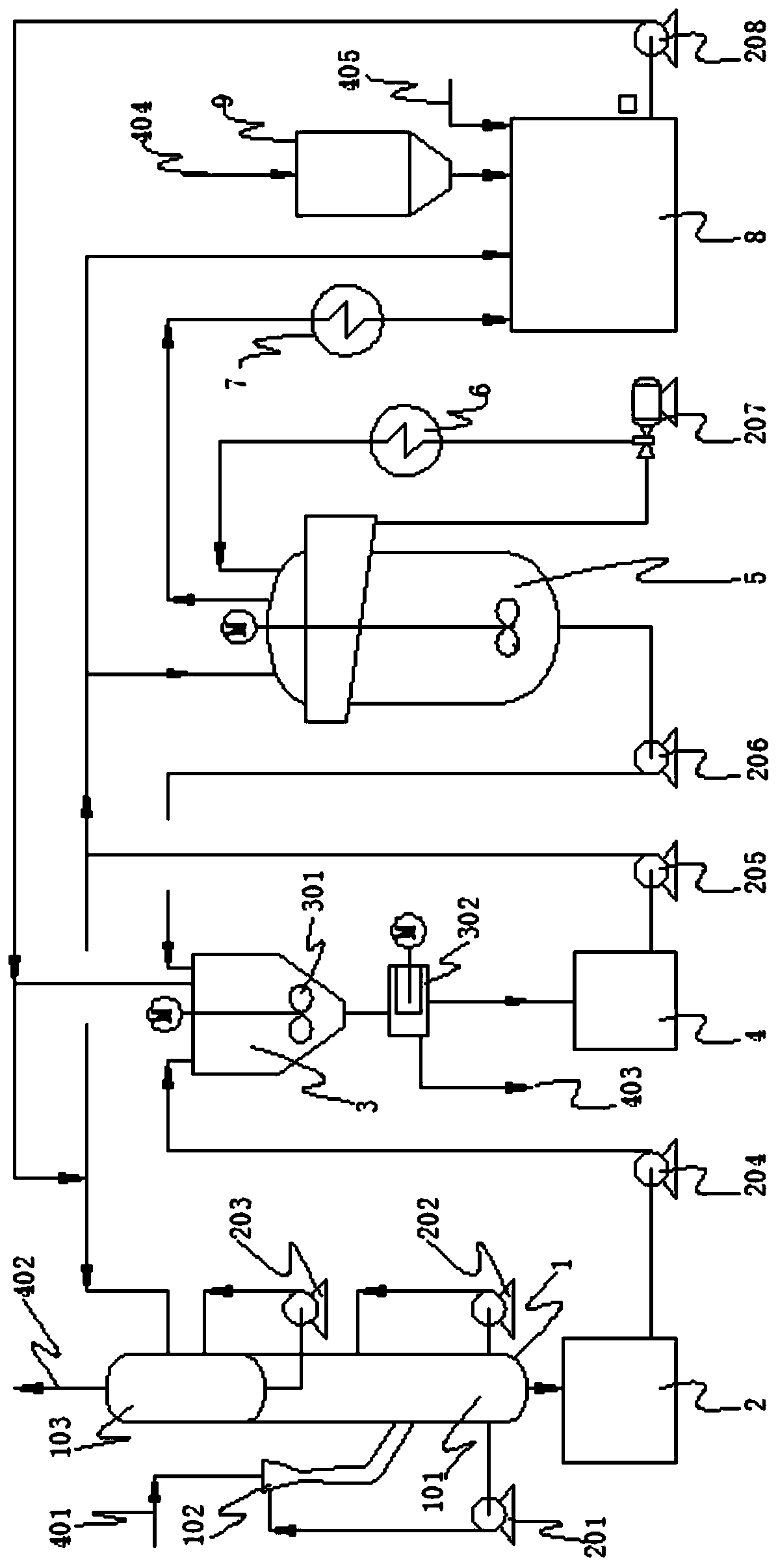

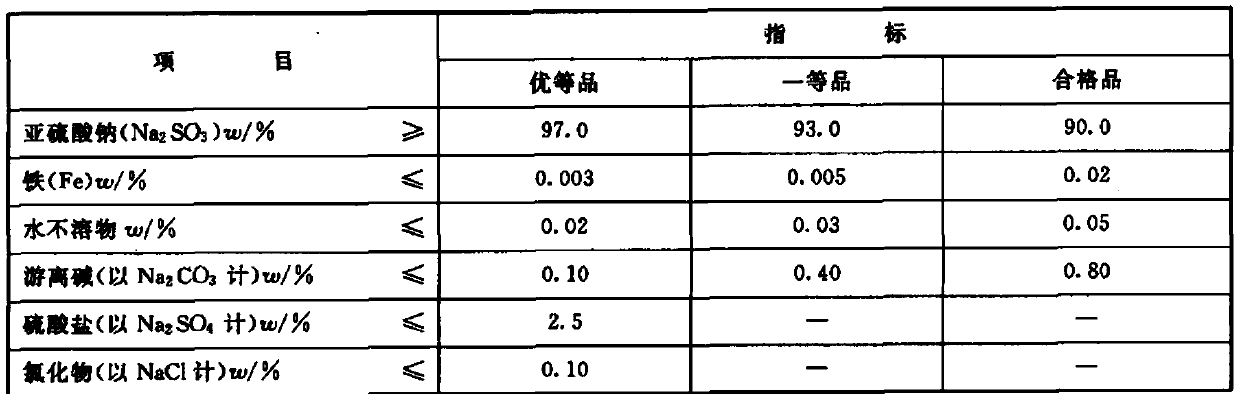

[0048] Flue gas desulfurization by-product sodium sulfite system using solid soda ash as sodium source. The main steps are as follows:

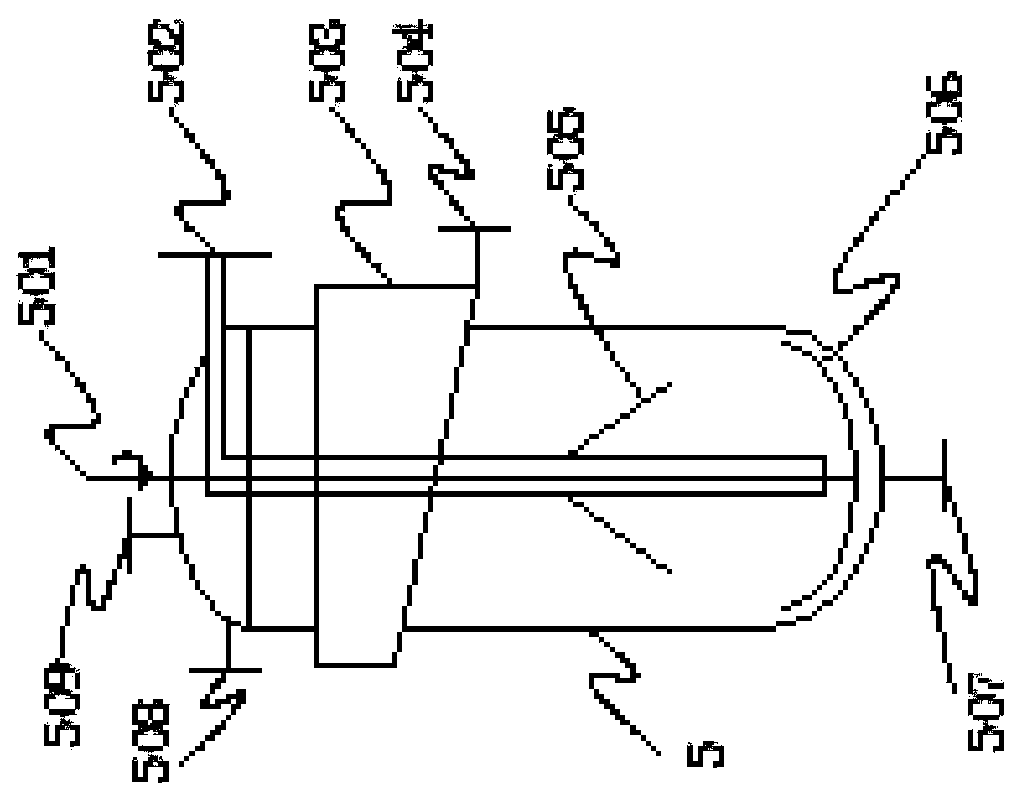

[0049] ① Alkali configuration and gas absorption. The sulfur-containing flue gas enters the lower part of the absorption tower (1) after being absorbed in the Venturi absorber (102) with the absorption liquid conveyed from the lower end of the absorption tower (101), and then flows between the lower end of the absorption tower (101) and the upper section of the absorption tower ( 103) Continue countercurrent absorption, and the absorbed tail gas (402) leaves the system from the top of the absorption tower; the lye in the lye tank is transported to the upper section of the absorption section (103), and the upper section of the absorption section (103) absorbs the absorption of the flue gas The liquid is transported to the lower part of the absorption tower (101), and the absorption liquid after the lower part of the absorption tower (101) abs...

Embodiment 2

[0063] Flue gas desulfurization by-product sodium sulfite system using solid caustic soda or sodium hydroxide powder as sodium source. The main steps are as follows:

[0064] ①Alkaline configuration. The sulfur-containing flue gas enters the lower part of the absorption tower (1) after being absorbed in the Venturi absorber (102) with the absorption liquid conveyed from the lower end of the absorption tower (101), and then flows between the lower end of the absorption tower (101) and the upper section of the absorption tower ( 103) Continue countercurrent absorption, and the absorbed tail gas (402) leaves the system from the top of the absorption tower; the lye in the lye tank is transported to the upper section of the absorption section (103), and the upper section of the absorption section (103) absorbs the absorption of the flue gas The liquid is transported to the lower part of the absorption tower (101), and the absorption liquid after the lower part of the absorption to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com