Efficient grain-saving flavor-type fermented compound feed for fattening pigs and preparation method thereof

A technology for compound feed and fattening pigs, which is applied in the field of high-efficiency, grain-saving and flavored fermented compound feed for fattening pigs and its preparation. It can solve the problems of resource waste, unscientific utilization, and insufficient use, and achieve enhanced immune function and reduced natural toxicity. , the effect of reducing environmental emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

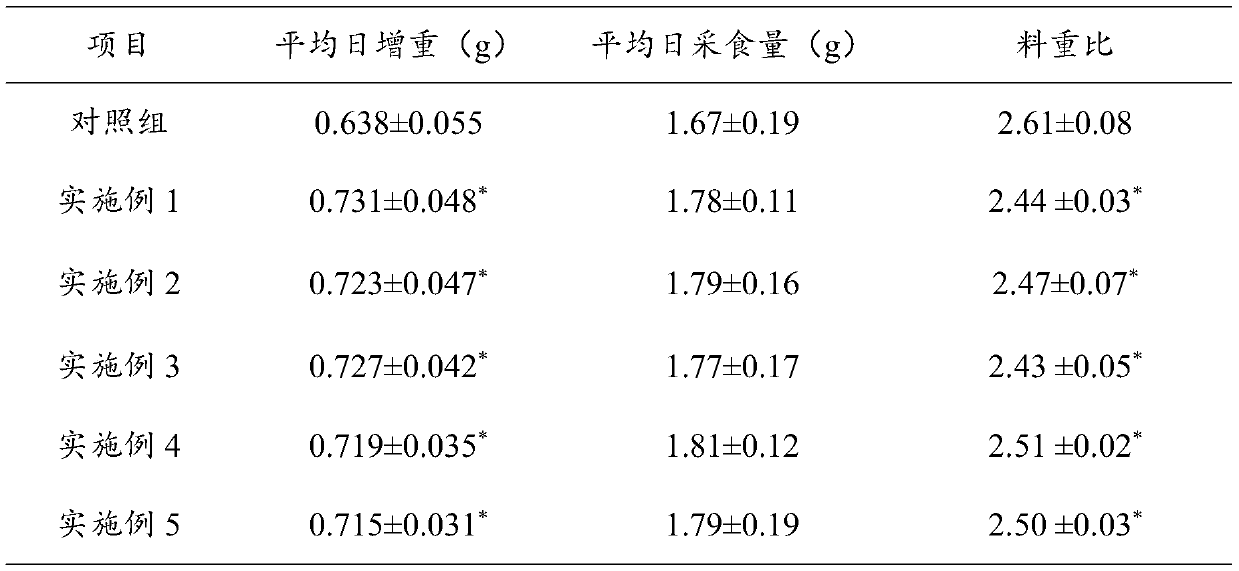

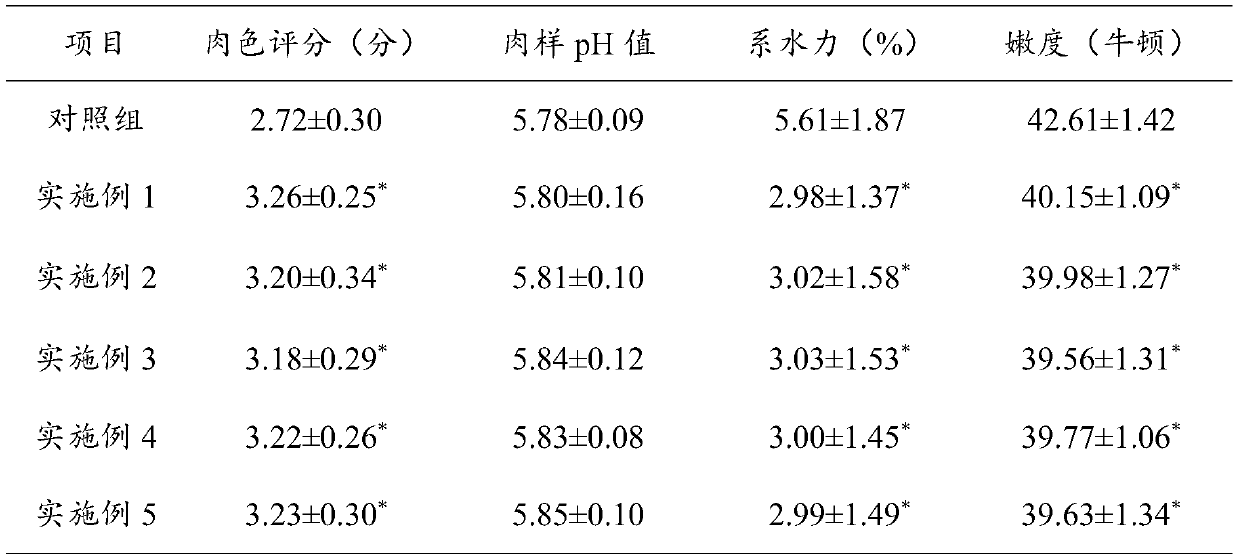

Embodiment 1

[0029] A high-efficiency, grain-saving and flavor-type fermented compound feed for fattening pigs is prepared by solid-state fermentation of the following raw materials: 25.00 parts of water, 8.92 parts of puffed soybean meal, 3.96 parts of steam-exploded peanut seedling powder, and 3.71 parts of steam-exploded bean curd residue 11.78 parts of puffed brown rice flour, 1.27 parts of puffed peanut kernel meal, 56.51 parts of corn, 3.58 parts of puffed soybean meal, 3.38 parts of soybean oil, 0.16 part of calcium carbonate, 1.40 part of calcium hydrogen phosphate, 0.20 part of table salt, 0.50 part of sodium bicarbonate, 0.15 parts of trace element compound premix, 0.15 parts of vitamin compound premix, 0.37 parts of L-lysine, 0.01 part of DL-methionine, 0.04 parts of L-threonine, 0.41 parts of glucose, 0.45 parts of fermented bacteria preparation, plant 0.40 parts of extract, 0.02 parts of phytase, 0.03 parts of compound enzyme preparation, 0.10 parts of lactic acid, 0.55 parts o...

Embodiment 2

[0039] A high-efficiency, grain-saving and flavor-type fermented compound feed for fattening pigs is prepared by solid-state fermentation of the following raw materials: 25.20 parts of water, 9.36 parts of puffed soybean meal, 4.26 parts of steam-exploded peanut seedling powder, and 3.83 parts of steam-exploded bean curd residue 10.94 parts of puffed brown rice flour, 1.82 parts of puffed peanut kernel meal, 56.67 parts of corn, 2.80 parts of puffed soybean meal, 3.53 parts of soybean oil, 0.35 part of calcium carbonate, 1.05 part of calcium hydrogen phosphate, 0.25 part of table salt, 0.45 part of sodium bicarbonate, Trace element compound premix 0.15 parts, vitamin compound premix 0.15 parts, L-lysine 0.39 parts, DL-methionine 0.02 parts, L-tryptophan 0.01 parts, L-threonine 0.05 parts, glucose 0.42 parts , 0.45 parts of fermented bacteria preparations, 0.35 parts of plant extracts, 0.03 parts of phytase, 0.03 parts of compound enzyme preparations, 0.10 parts of lactic acid, ...

Embodiment 3

[0049] A high-efficiency, grain-saving and flavor-type fermented compound feed for fattening pigs is prepared by solid-state fermentation of the following raw materials: 25.40 parts of water, 9.79 parts of puffed soybean meal, 4.57 parts of steam-exploded peanut seedling powder, and 3.95 parts of steam-exploded bean curd residue 10.09 parts of puffed brown rice flour, 2.38 parts of puffed peanut kernel meal, 56.83 parts of corn, 2.03 parts of puffed soybean meal, 3.69 parts of soybean oil, 0.53 part of calcium carbonate, 0.70 part of calcium hydrogen phosphate, 0.30 part of table salt, 0.40 part of sodium bicarbonate, Trace element compound premix 0.15 parts, vitamin compound premix 0.15 parts, L-lysine 0.40 parts, DL-methionine 0.02 parts, L-tryptophan 0.01 parts, L-threonine 0.06 parts, glucose 0.43 parts , 0.45 parts of fermented bacteria preparations, 0.30 parts of plant extracts, 0.03 parts of phytase, 0.03 parts of compound enzyme preparations, 0.10 parts of lactic acid, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com