Method for preparing controlled-release culture soil based on garbage soil

A technology of waste soil and aquaculture soil, applied in the fields of botanical equipment and methods, planting substrates, culture medium, etc., can solve the problems of landfill site selection, inability to find suitable sites, re-construction and reuse of landfills Accurate and other problems, to achieve the effect of being conducive to sustainable development and utilization, low cost of raw materials, and easy large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

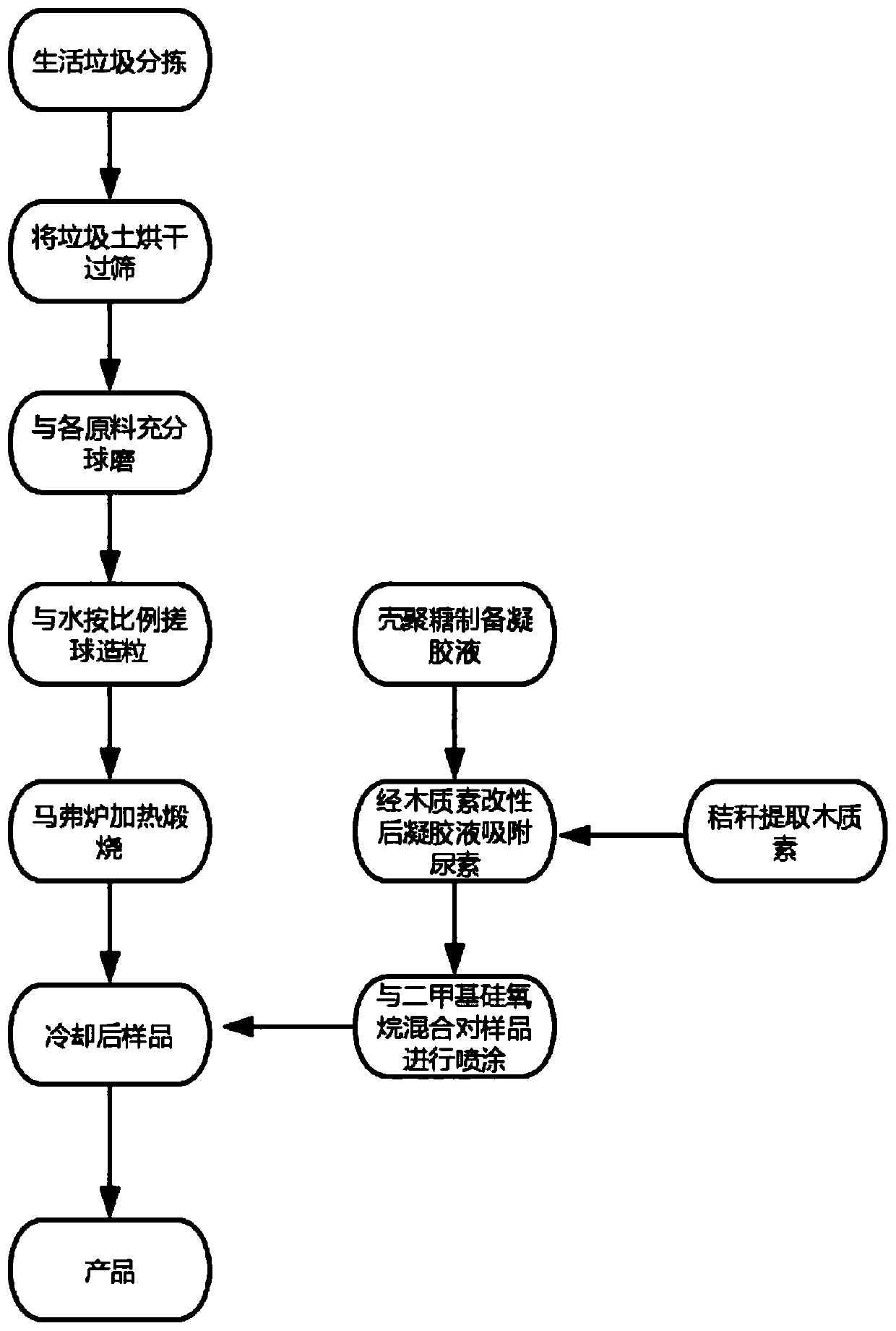

[0029] The following embodiments will further describe the present invention in detail in conjunction with the flow chart.

[0030] The raw garbage soil of the present invention is obtained from domestic garbage treatment stations, and the garbage soil contains nitrogen, phosphorus, potassium and organic matter components effective for farmland, and its heavy metal content is lower than the fertilizer standard.

[0031] specific process

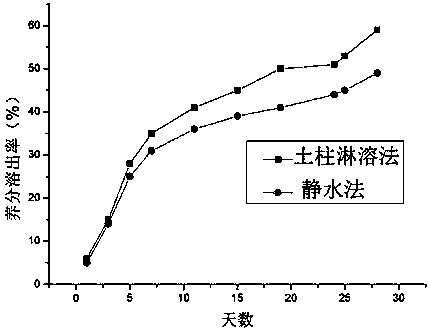

[0032] according to figure 1 As shown in the flow chart, dry the garbage soil and pass it through a 200-mesh sieve. Put 10g of the prepared garbage soil, 4g of bentonite, 3g of plant ash, and 2g of phosphate rock powder into a ball mill at 90r / min for 2 hours. Stir at 1.25g / ml, then granulate, the particle size is 3-6mm, put it into the muffle furnace to heat up, first preheat 400°C, keep it warm for 1h, then continue heating to 800°C, hold it for 1h, and then lower it to room temperature taking out, and then spraying the lignin-modified c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com