Biological organic fertilizer produced by using household garbage buried for years

A bio-organic fertilizer and domestic garbage technology, applied in the field of solid waste treatment, can solve the problems of acute landfill re-construction and reuse, failure to find suitable sites, and difficulties in site selection for landfills, and achieve favorable results Sustainable development and utilization, improvement of quality and taste, and effects of controlling pests and diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

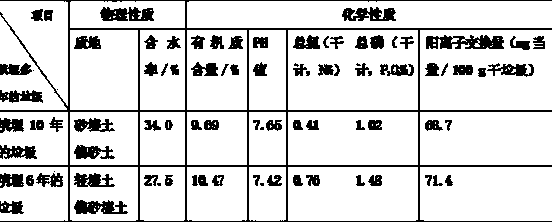

Image

Examples

Embodiment 1

[0023] Example 1: Stir 5kg Japanese enzyme bacteria expansion bacteria, 4kg modified zeolite powder, 10kg dried chicken manure, 16kg rice bran, 8kg phosphate rock powder, and 1000kg garbage nutrient soil for fermentation, and turn over every day according to the fermentation temperature Throwing, keep the temperature between 60-70°C on the first and second days, keep the temperature between 40-50°C on the third and fourth days, keep the normal temperature on the fifth and sixth days, and then you can get powdery bioorganic Fat.

Embodiment 2

[0024] Embodiment 2: Preparation of garbage nutrient soil: ① Sorting domestic garbage that has been buried for many years on the spot: metals, construction waste, and plastic products are sorted out; ② Air-dry or dry the remaining domestic garbage after sorting; ③ Vibrate and sieve out the granular and powdery garbage nutrient soil, and pull the garbage nutrient soil to the production plant for standby. Mix 1000kg of the waste nutrient soil obtained above and 10kg of Japanese enzyme bacteria expansion bacteria, 6kg of modified zeolite powder, 18kg of dried chicken manure, 12kg of phosphate rock powder, and 22kg of rice bran. Turn over and throw, keep the temperature between 60-70°C on the first and second days, keep the temperature between 40-50°C on the third and fourth days, keep the normal temperature on the fifth and sixth days, and then you can get powdery organisms Organic Fertilizer.

Embodiment 3

[0025] Embodiment 3: Preparation of garbage nutrient soil: ① Sorting domestic garbage that has been buried for many years on the spot: metal, construction waste, and plastic products are sorted out; ② Air-dry or dry the remaining domestic garbage after sorting; ③ Vibrate and sieve out the granular and powdery garbage nutrient soil, and pull the garbage nutrient soil to the production plant for standby. Preparation of modified zeolite powder: Grinding zeolite into a powder with a particle size of 180 mesh, and fermenting at 280° C. for 6 hours to obtain modified zeolite powder. Mix 1000kg of the waste nutrient soil above, 5kg of modified zeolite powder and 7kg of Japanese enzyme bacteria expansion bacteria, 14kg of dried duck manure, 9kg of phosphate rock powder, and 19kg of rice bran. Turn over and throw, keep the temperature between 60-70°C on the first and second days, keep the temperature between 40-50°C on the third and fourth days, keep the normal temperature on the fifth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com