A kind of ladle refining furnace refining slag recycling method

A technology for ladle refining furnace and refining slag, applied in the field of iron and steel metallurgy, can solve the problems of high cost of synthetic slag, LF refining slag cannot be reused, etc., and achieve the effect of high production stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

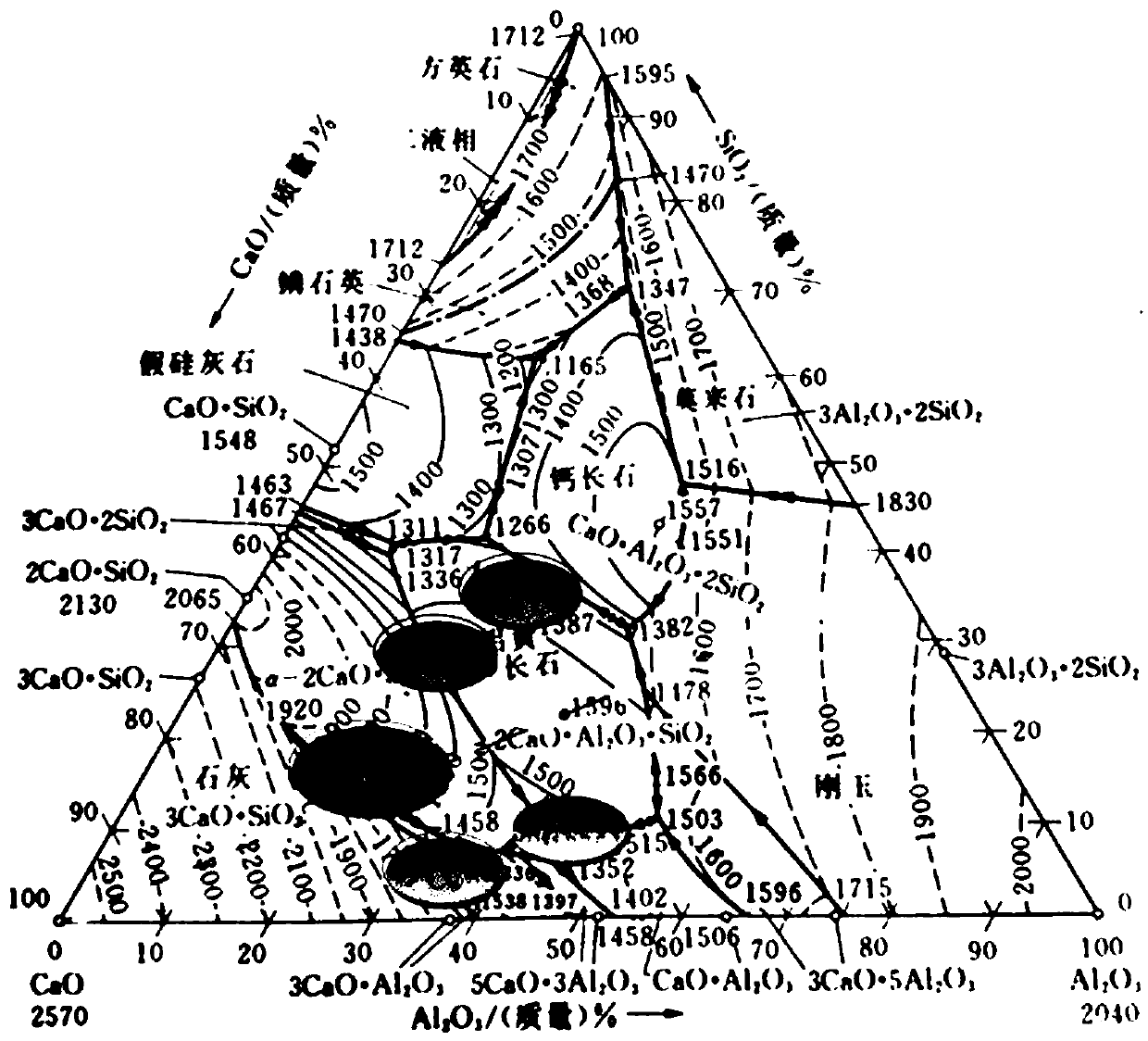

[0035] The following examples are combined with figure 1 A method for recycling refining slag is further described.

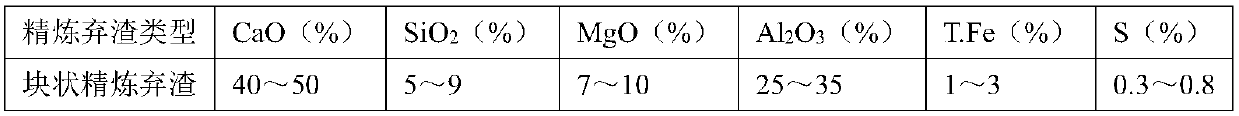

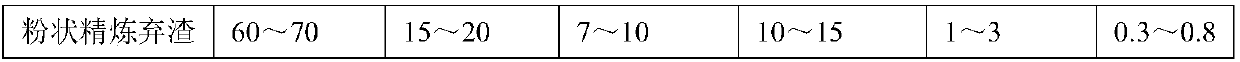

[0036] Select the refining waste slag of aluminum-killed steel, and pour the refining slag into the slag basin through the following procedures—recover the refining slag in the slag yard—natural cooling—crushing to a particle size less than 100mm—magnetic separation—sieving—recovering blocks Shaped refining waste residue (≥10mm)——Recover powdery refining waste residue (﹤10mm)

[0037] Mix the massive refining waste slag and lime as synthetic slag. The mixing ratio of massive refining waste slag and lime is 1:2. It is added with the steel flow during the process of converter tapping, and the amount of addition is 6kg. slag / ton of steel, and aluminum deoxidizer is added during the tapping process, the addition amount is about 1kg aluminum / ton of steel, and the aluminum deoxidizer reacts to form Al 2 o 3 , the resulting deoxidation product Al 2 o 3 The amount...

Embodiment 2

[0040] The following examples are shown together with the device figure 1 A method for recycling refining slag is further described.

[0041] Select the refining waste slag of aluminum-killed steel, and pour the refining slag into the slag basin through the following procedures—recover the refining slag in the slag yard—natural cooling—crushing to a particle size less than 100mm—magnetic separation—sieving—recovering blocks Shaped refining waste residue (≥3mm)——Recover powdery refining waste residue (﹤3mm)

[0042] Mix the massive refining waste slag and lime as synthetic slag, the mixing ratio of massive refining waste slag and lime is 1:4, and add it with the steel stream during the process of converter tapping, and the addition amount is 8kg synthetic slag slag / ton of steel, and aluminum deoxidizer is added during the tapping process, the addition amount is about 1kg aluminum / ton of steel, and the aluminum deoxidizer reacts to form Al 2 o 3 , the resulting deoxidation pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com