Fuel cell and bipolar plate and bipolar plate assembly for fuel cell

A fuel cell and membrane electrode assembly technology, which is applied to fuel cell parts, fuel cells, electrical components, etc., can solve the problems of high processing and testing equipment requirements, difficult processing, and high manufacturing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

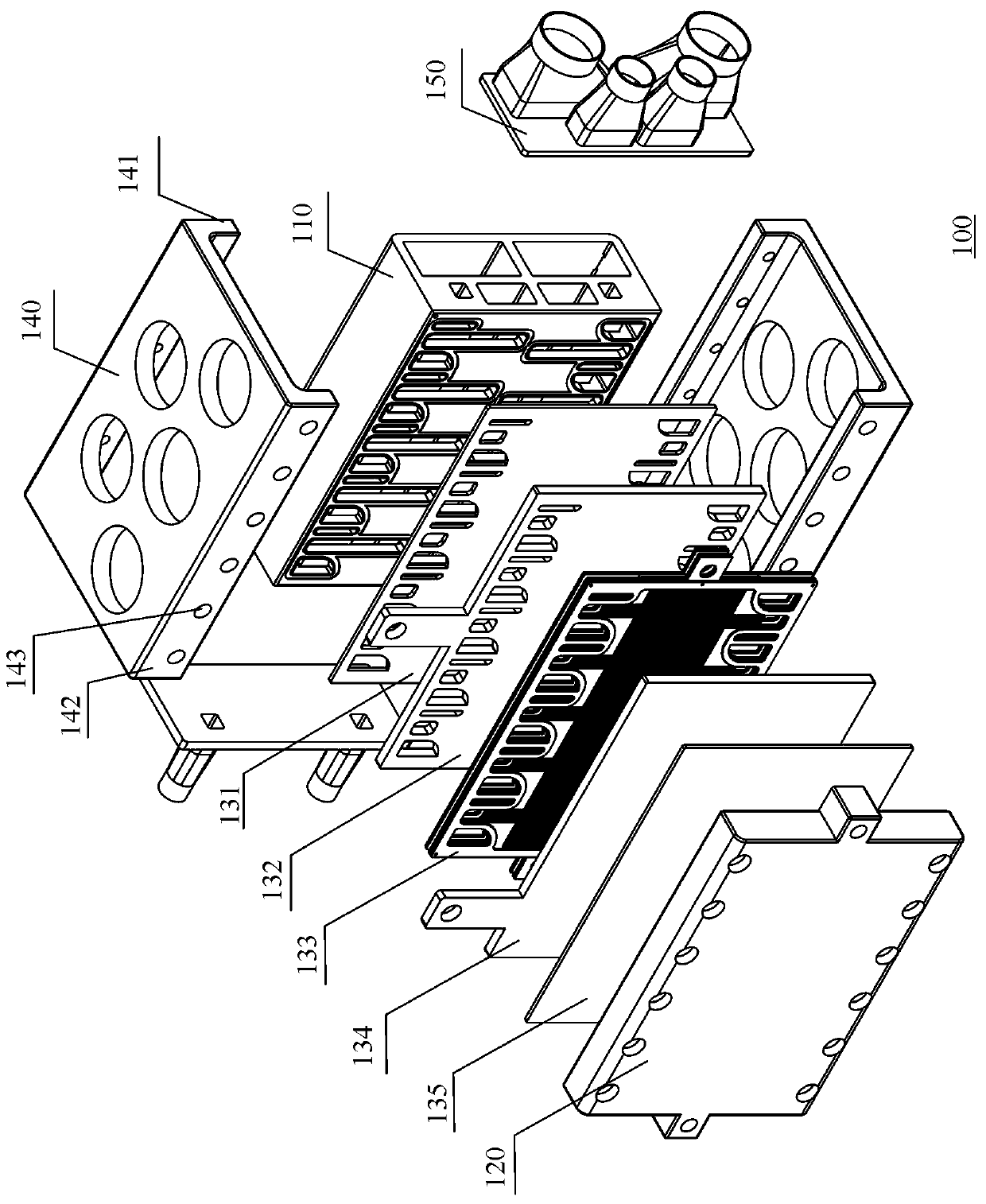

[0141] figure 1 A schematic perspective view showing a disassembled state of the fuel cell according to the first embodiment of the present invention. The fuel cell 100 includes a first end plate 110 and a second end plate 120 facing each other, between which a first insulating plate 131 , a first current collector 132 , a repeat part 133 , a second current collector are sequentially stacked. The current collector 134 and the second insulating plate 135 . The first end plate 110 doubles as a flow distribution device for distributing fuel fluid, oxidizing gas and cooling medium to the bipolar plates in the repeating member 133 .

[0142] The fuel fluid includes gaseous hydrogen, or a fluid composed of fuel such as liquid methanol or methanol solution. The oxidizing gas can be air or pure oxygen, and the cooling medium can be liquid or gas.

[0143] The repeating part 133 includes bipolar plates and the membrane electrode assembly 103 sandwiched between the bipolar plates. T...

no. 2 example

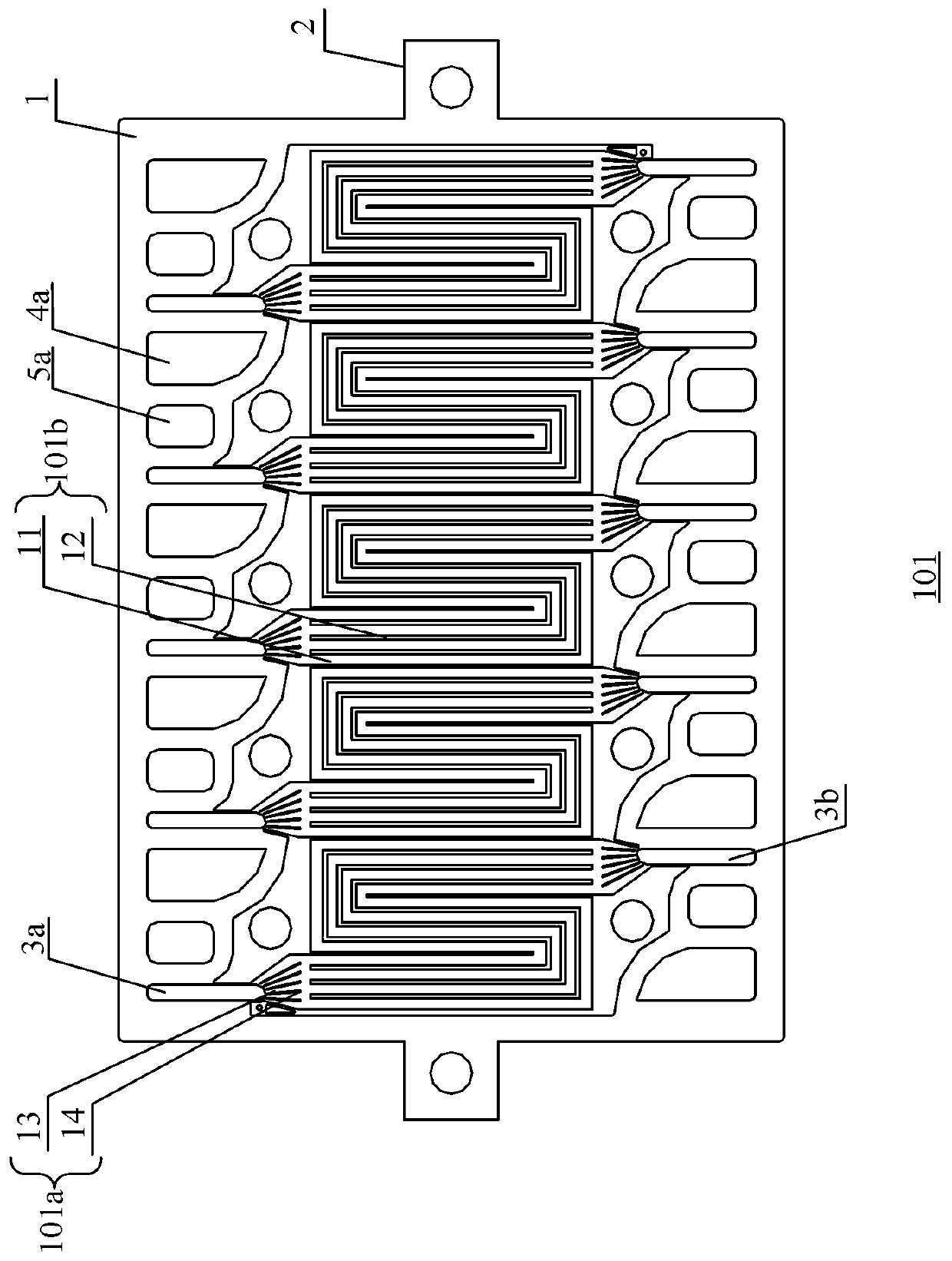

[0163] Figure 3a with 3b A bottom view and a top view of the anode plate according to the second embodiment of the present invention are respectively shown, wherein the view viewed from below the fuel cell is a bottom view, and the view viewed from above the fuel cell is a top view.

[0164] The anode plate 101 includes a substrate 1, a flow guide structure 101a and a flow field structure 101b for delivering fuel fluid on the first surface of the substrate 1, and a flow guide structure 101c and a flow field structure for delivering cooling medium on the second surface of the substrate 1 101d. The anode plate 101 has the functions of dispersing fuel fluid and conducting electrons, and can be made of materials with high mechanical strength and excellent electrical conductivity, such as graphite, stainless steel, titanium alloy, aluminum alloy, copper alloy, etc.

[0165] The substrate 1 is roughly rectangular in shape, including a first side and a second side opposite to each...

no. 3 example

[0183] The anode plate assembly according to the third embodiment includes an anode plate, a gasket and a sealing frame on the first surface of the anode plate, and a sealing frame on the second surface of the anode plate. The anode plate is, for example, the anode plate that has been described in detail above in connection with the second embodiment. For the sake of brevity, the internal structure of the anode plate will not be described in detail below. exist Figure 4 with 5 ,as well as Figure 12 Only the top view of the gasket on the first surface of the anode plate, the sealing frame on the first surface of the anode plate, and the sealing frame on the second surface of the anode plate in the anode plate assembly is shown.

[0184] Such as Figure 4 As shown, the gasket 136 in the anode plate assembly includes a first sub-piece 1361 and a second sub-piece 1362 . Near the first side of the substrate of the anode plate 101 , the first sub-sheet 1361 covers the top sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ridge width | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com