Seal-type cable sheath, manufacturing method thereof and temperature sensor sealing lead-out assembly

A technology of temperature sensor and manufacturing method, applied in cable/conductor manufacturing, thermometer, sealed casing, etc., can solve problems such as cooling oil leakage, and achieve the effect of avoiding leakage, long service life, and maintaining sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

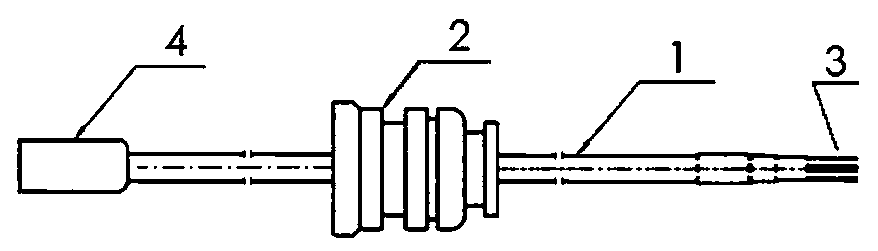

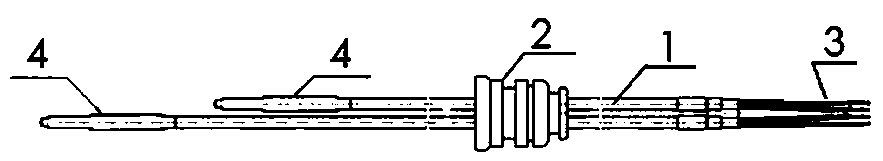

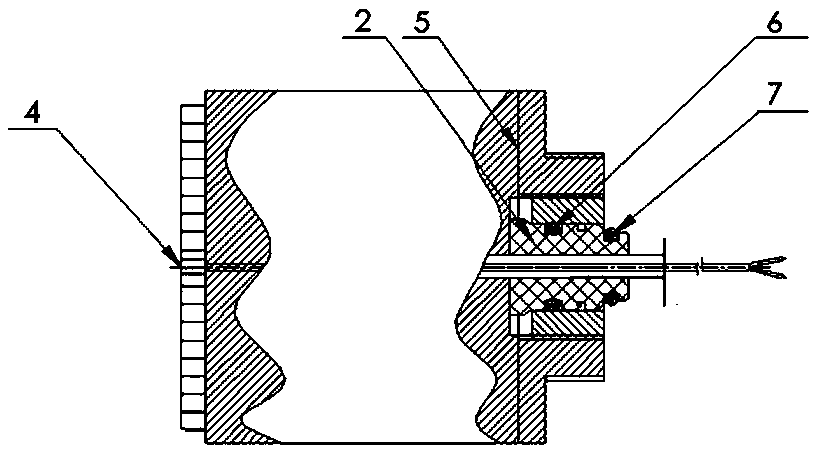

[0017] The sealed lead-out assembly of the temperature sensor disclosed in this patent application is realized based on a sealed cable sheath.

[0018] Taking the application of oil-cooled motors as an example, the temperature-sensing front end of the temperature sensor sealing lead-out assembly is set in the cooling oil circuit of the motor winding, and its signal cable is led out of the cooling oil cavity to transmit the temperature-sensing transmission signal to the signal acquisition and processing system. In its actual installation, the sealing between the signal cable and the oil cavity is realized by the sealed cable sheath of the present application. The sealed cable sheath of this patent application is not only the outer insulation protection layer of the signal transmission inner core cable 3, but also a sealing entity that ensures that the signal cable does not affect the sealing of the oil chamber after the temperature sensor is installed.

[0019] The sealed cable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com