Tube-type approximation and imaging unit mechanical tandem type scanning tunneling microscope body

An imaging unit and scanning tunneling technology, which is applied in the field of scanning probe microscopes, can solve the problems of high vibration intensity, loss of atomic-level imaging, and no low temperature conditions, etc., and achieve low starting voltage, simple structure, and strong rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

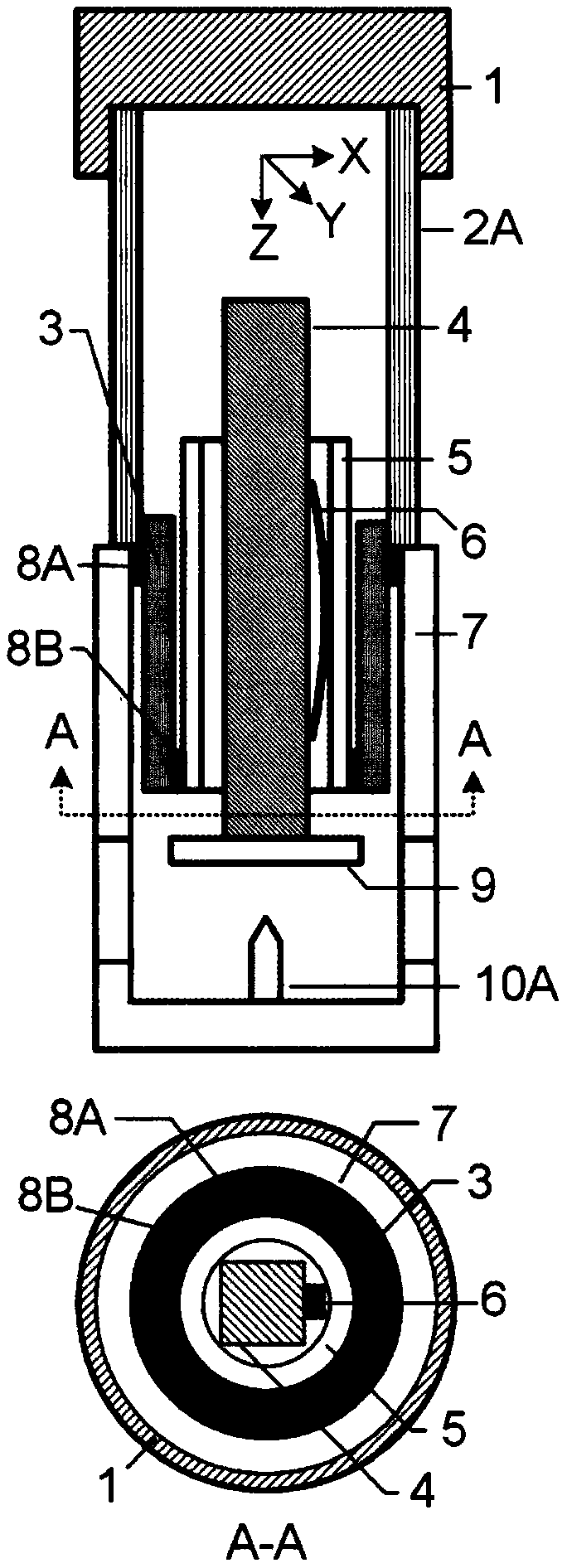

[0028] Embodiment 1: See for details figure 1 , a tubular approaching and imaging unit mechanical tandem scanning tunneling microscope mirror body, including a base 1, a slide bar 4, a sleeve 5 and a spring leaf 6, and is characterized in that it also includes a first piezoelectric tube 2A, a second piezoelectric tube An electric tube 3 and a probe holder 7, one end of the first piezoelectric tube 2A is fixed on the base 1, and the other end is a free end for deformation, and one end of the second piezoelectric tube 3 is in common with the free end of the first piezoelectric tube 2A. The shaft is fixed, the other end of the second piezoelectric tube 3 is a free end for deformation, the second piezoelectric tube 3 is a four-quadrant split piezoelectric tube, and the sleeve 5 is fixed concentrically and coaxially on the second piezoelectric tube 3 Deformation of the free end, the spring piece 6 exerts pressure along the radial direction of the casing 5 to elastically clamp the s...

Embodiment 2

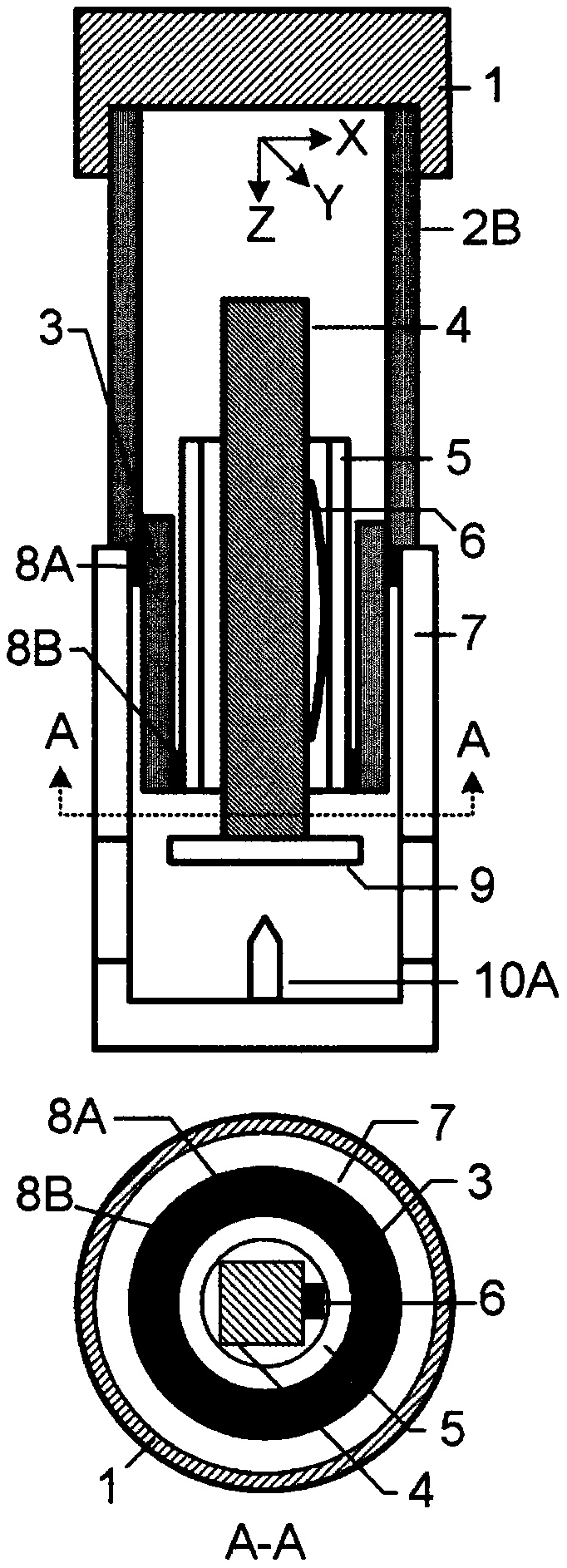

[0029] Embodiment 2: See for details figure 2 , a tubular approaching and imaging unit mechanical tandem scanning tunneling microscope mirror body, characterized in that: the first piezoelectric tube 2A external electrode is 2B of XYZ piezoelectric tubes arranged in four quadrants along the axial direction, the second piezoelectric tube The tube 3 and the first piezoelectric tube 2B are also arranged in four quadrants with external electrodes, and the external electrodes can be short-circuited one by one in the axial direction and share electrodes, thereby effectively reducing control signals and control lines.

Embodiment 3

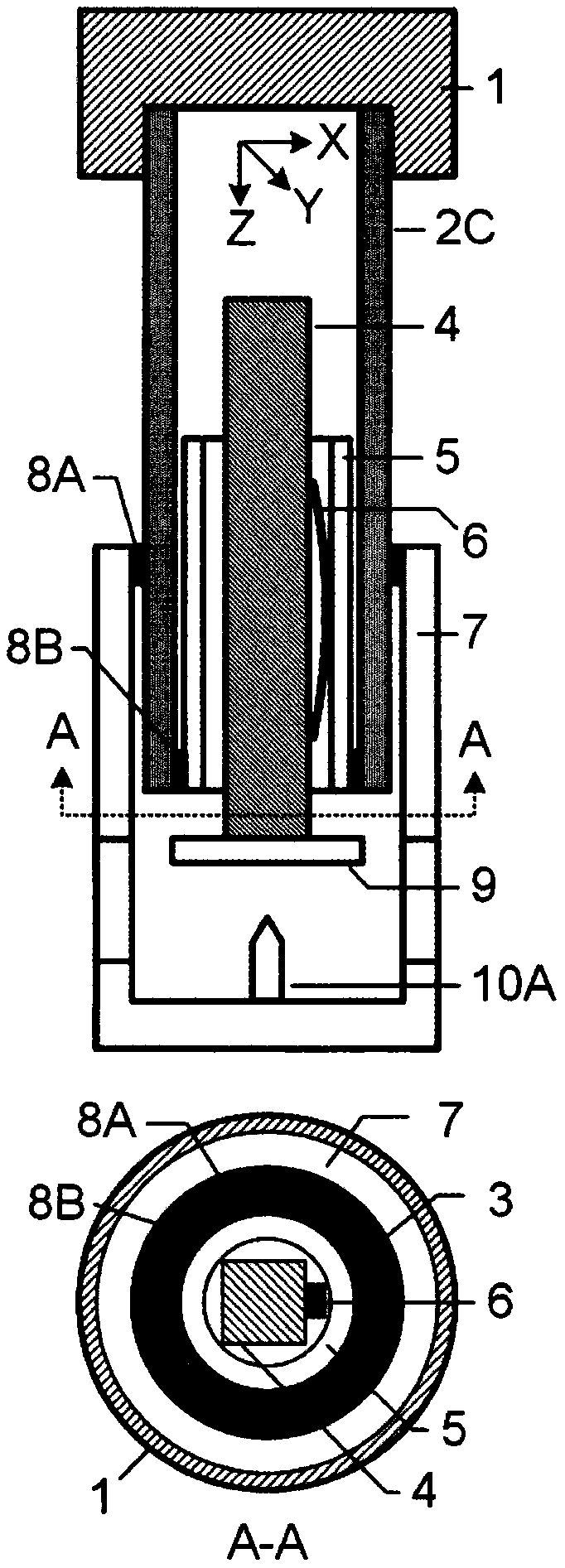

[0030] Embodiment 3: See for details image 3 , a tubular approximation and imaging unit mechanical tandem scanning tunneling microscope mirror body, characterized in that: the first piezoelectric tube 2B and the second piezoelectric tube 2C are integrally arranged to simplify the mirror body structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com