Method for detecting quality of conductive tube based on relative motion

A relative motion, conductive tube technology, applied in measuring devices, material analysis by electromagnetic means, instruments, etc., can solve problems such as inapplicability, not involving information collection and analysis, and limitations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Testing material: T2 red copper rod, diameter 7.92mm, length 305mm, Figure 6 Photos of samples for testing;

[0062] Binding post interval / information collection area length: 30mm;

[0063] Input constant current: 1.3A;

[0064] Movement mode: the detection device is stationary, and the sample moves;

[0065] Sample movement speed: 30mm / s;

[0066] Signal acquisition frequency: 20 times / s;

[0067] Standard conductivity: 99.8%IACS;

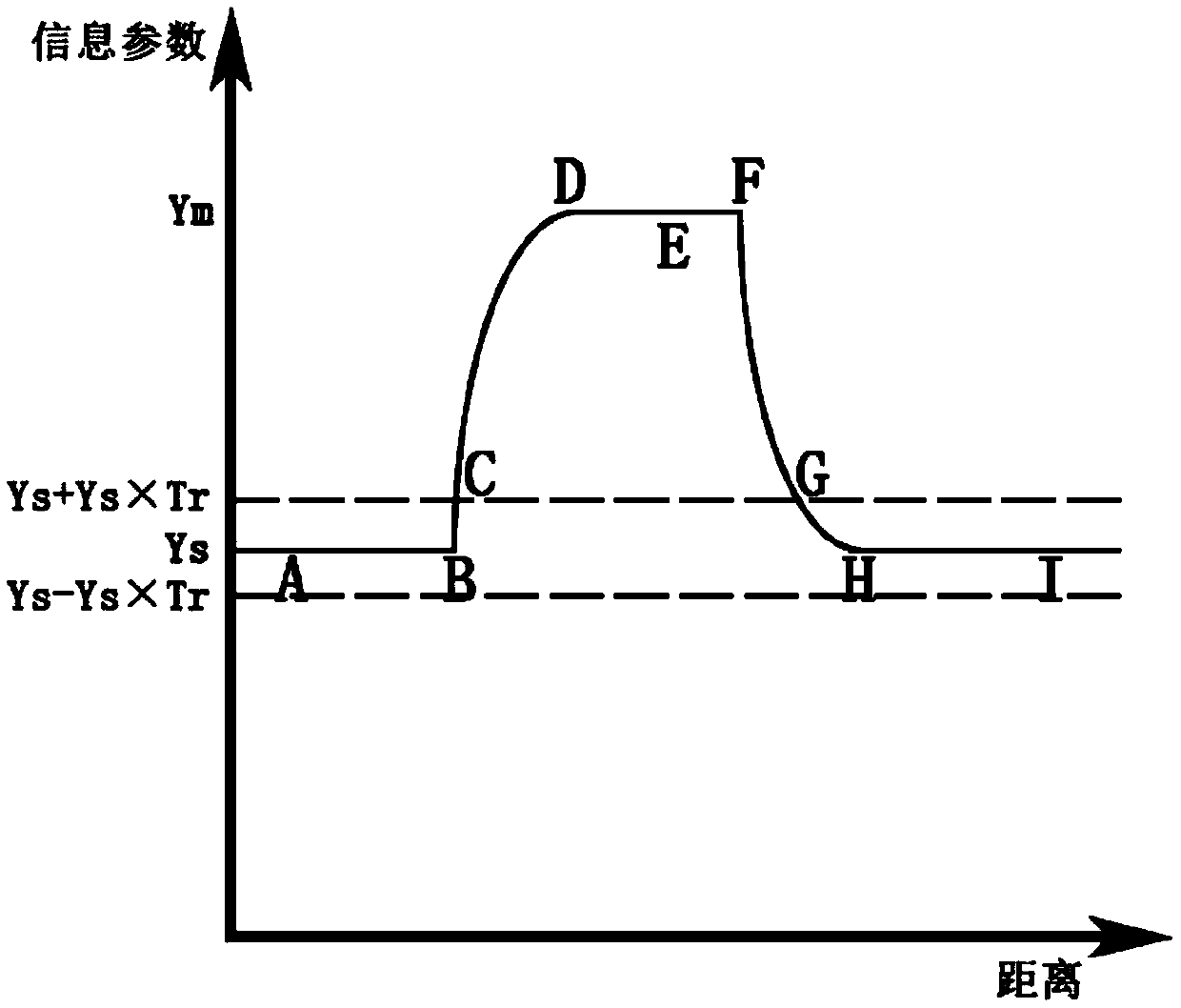

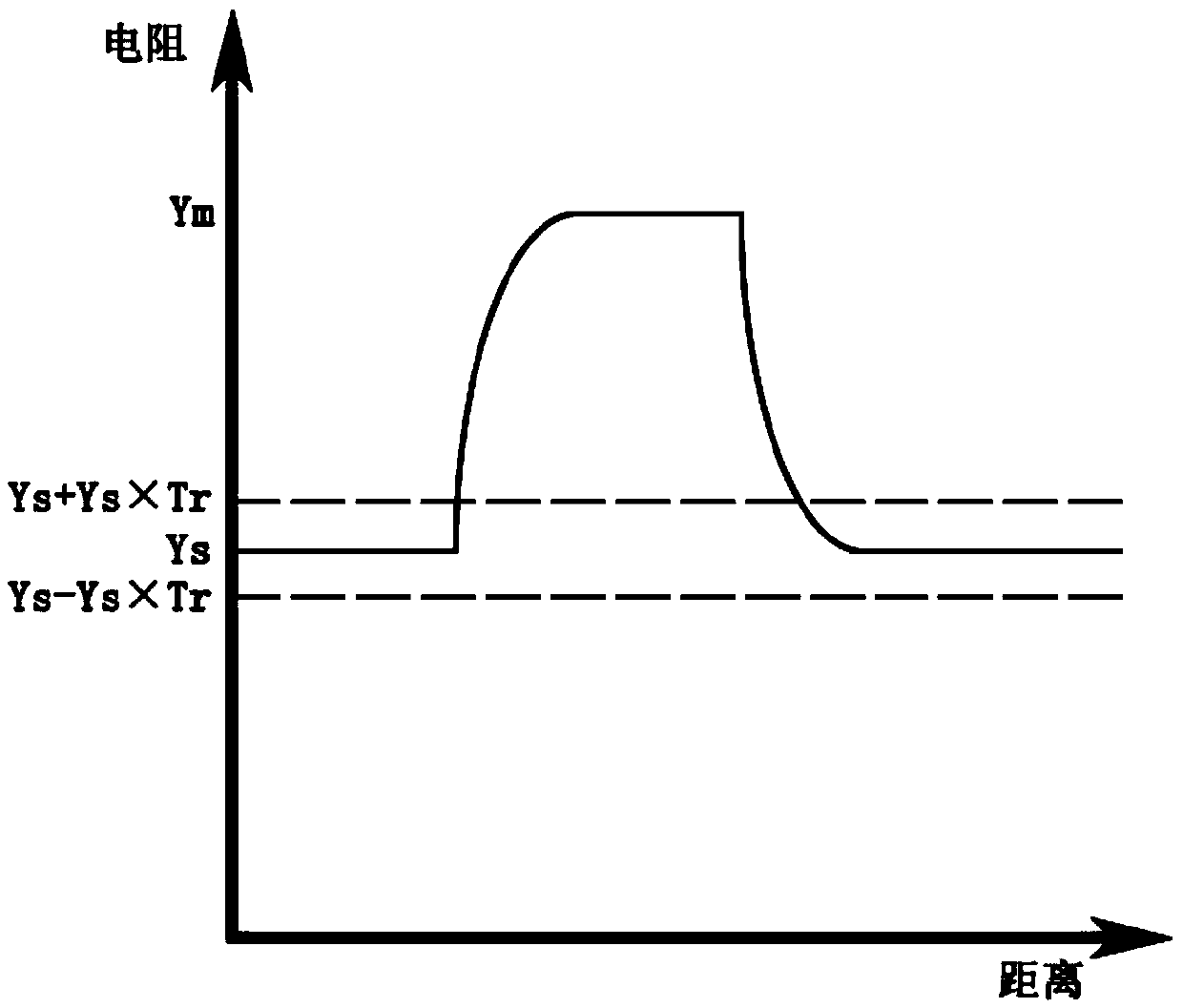

[0068] Figure 7 is the obtained conductivity-distance curve, T r =0.003, according to |actual conductivity-standard conductivity| / standard conductivityr , it is judged that there is no defect, and the sample is qualified.

Embodiment 2

[0070] Detection material: stainless steel pipe, outer diameter 20mm, inner diameter 18mm, length about 23cm, Figure 8 Photos of samples for testing;

[0071] Binding post interval / information collection area length: 50mm;

[0072] Input constant current: 2.3A;

[0073] Movement mode: the detection device is stationary, and the sample moves;

[0074] Sample movement speed: 30mm / s;

[0075] Signal collection frequency: 30 times / s;

[0076] Standard conductivity: 0.139MS / m;

[0077] Figure 9 is the obtained conductivity-distance curve, T r =0.0144, according to |actual conductivity-standard conductivity| / standard conductivity≥T r , it is determined that there are 2 defects. The conductivity drops abnormally within the range of 19mm-20mm, corresponding to the first defect entering the information collection area, Y m1 =0.132mMS / m, the electrical conductivity within the position range of 69mm-70mm returns to normal, and the corresponding defect leaves the information co...

Embodiment 3

[0080] Testing material: aluminum alloy bar, diameter 5mm, length 800mm;

[0081] Binding post interval / information collection area length: 100mm;

[0082] Input constant current: 1.0A;

[0083] Movement mode: the detection device is stationary, and the sample moves;

[0084] Sample movement speed: 30mm / s;

[0085] Signal acquisition frequency: 60 times / s;

[0086] Standard voltage: 0.14418mV;

[0087] Figure 11 is the obtained voltage-distance curve, T r =0.001645, according to|actually measured voltage signal-standard voltage signal| / standard voltage signal≥T r , it is determined that there is 1 defect. The voltage rises abnormally within the range of 310mm-364mm, and the corresponding defect enters the information collection area, Y m =0.14635mV, the voltage within the range of 410mm-464mm returns to normal, the corresponding defect leaves the information collection area, the distances between the start point and end point of the defect and the start point of infor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Movement speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com