Online steel wire rod cold heading test recording method and system

A technology of recording system and recording method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

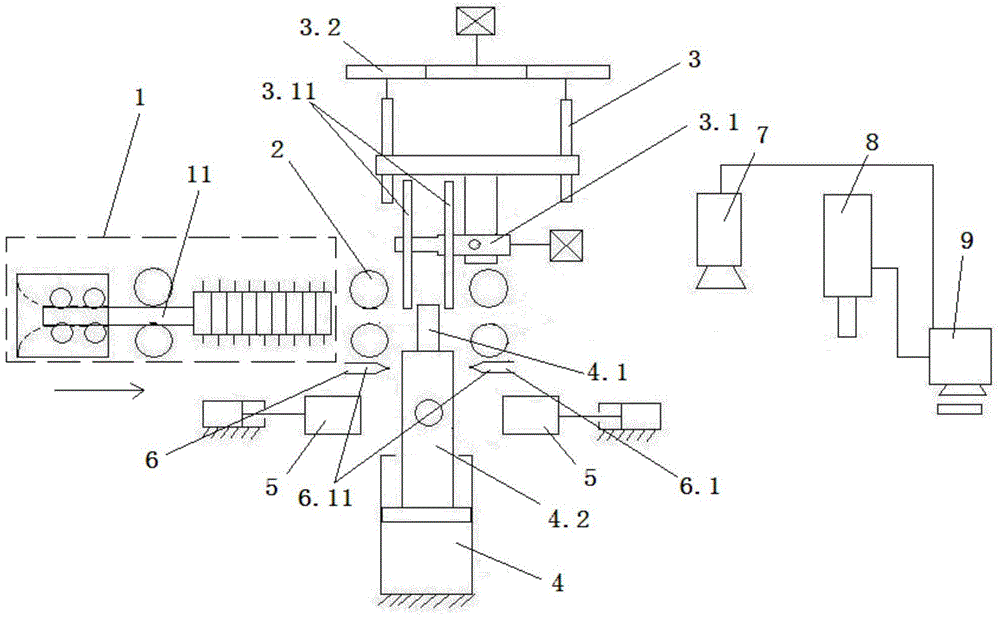

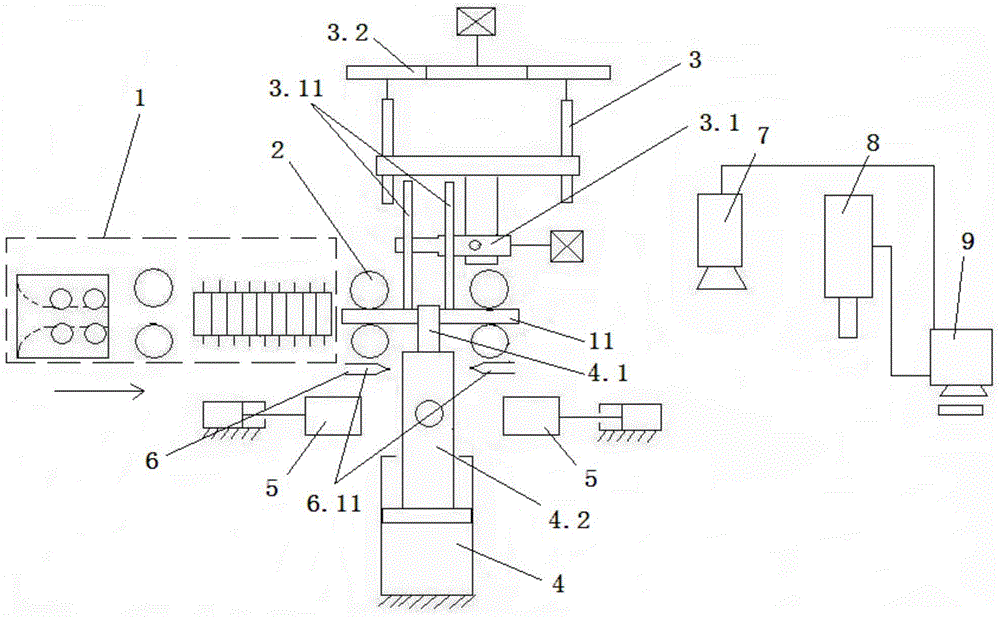

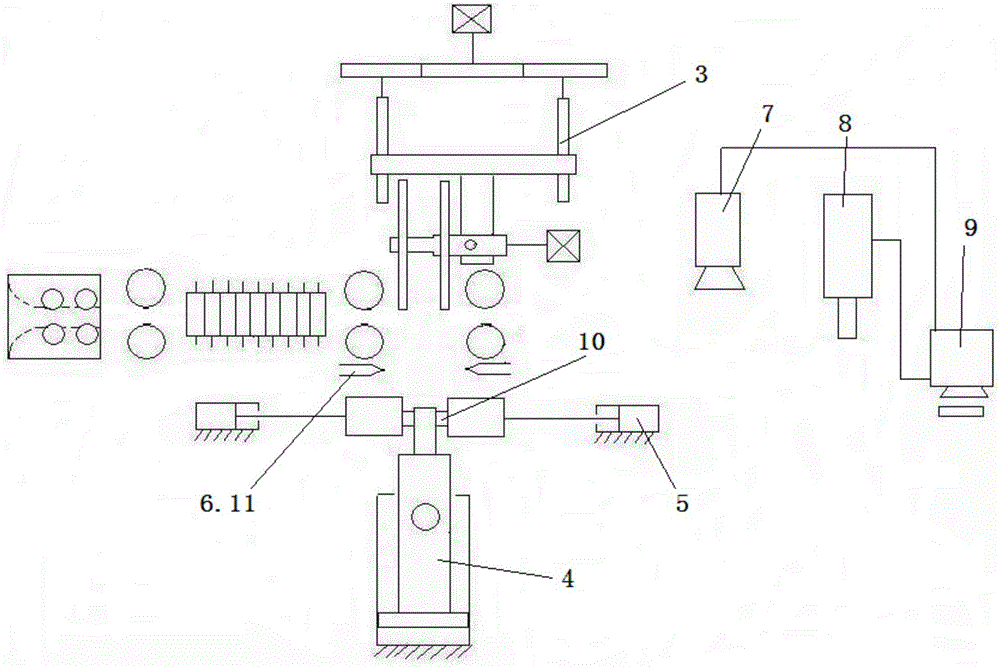

[0052] see Figure 1-Figure 6 , taking the cold heading steel wire rod of φ5.5mm as an example, the method of the present invention is further explained.

[0053] 1) The 300mm wire rod 11 intercepted from the wire rod production line is sent to the straightening system 1 for straightening, and the straightening system 1 includes a rough leveler and a fine leveler;

[0054] 2) Send the straightened wire rod 11 to the first clamping device 4 through the conveying system 2 (in this embodiment, pinch rollers are used);

[0055] 3) The first clamping device 4 includes a first driving device 4.2 and a first sample holder 4.1, and drives the two U-shaped chucks 4.11 of the first sample holder 4.1 under the drive of the first driving device 5.2 by radial clamping Tighten the wire rod 11;

[0056] 4) After the first sample holder 4.1 clamps the wire rod, the cutting system 3 is started, and the third driving device 3.2 of the cutting system 3 drives the two cutting wheels 3.11 of the...

Embodiment 2

[0063] see Figure 1-Figure 6 , taking the cold heading steel wire rod of φ6.5mm as an example, the method of the present invention is further explained.

[0064] 1) The 300mm wire rod 11 intercepted from the wire rod production line is sent to the straightening system 1 for straightening, and the straightening system 1 includes a rough leveler and a fine leveler;

[0065] 2) Send the straightened wire rod 11 to the first clamping device 4 through the conveying system 2 (in this embodiment, pinch rollers are used);

[0066] 3) The first clamping device 4 includes a first driving device 4.2 and a first sample holder 4.1, and drives the two U-shaped chucks 4.11 of the first sample holder 4.1 under the drive of the first driving device 5.2 by radial clamping Tighten the wire rod 11;

[0067] 4) After the first sample holder 4.1 clamps the wire rod, the cutting system 3 is started, and the third driving device 3.2 of the cutting system 3 drives the two cutting wheels 3.11 of the...

Embodiment 3

[0074] see Figure 1-Figure 6 , taking the cold heading steel wire rod of φ8.5mm as an example, the method of the present invention is further explained.

[0075] 1) The 300mm wire rod 11 intercepted from the wire rod production line is sent to the straightening system 1 for straightening, and the straightening system 1 includes a rough leveler and a fine leveler;

[0076] 2) Send the straightened wire rod 11 to the first clamping device 4 through the conveying system 2 (in this embodiment, pinch rollers are used);

[0077] 3) The first clamping device 4 includes a first driving device 4.2 and a first sample holder 4.1, and drives the two U-shaped chucks 4.11 of the first sample holder 4.1 under the drive of the first driving device 5.2 by radial clamping Tighten the wire rod 11;

[0078] 4) After the first sample holder 4.1 clamps the wire rod, the cutting system 3 is started, and the third driving device 3.2 of the cutting system 3 drives the two cutting wheels 3.11 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com